|

Crankshaft drive bearing

Remove Remove

| 2. |

Remove manual transmission from engine

|

| 4. |

Detach thrust plate and clutch disk

|

|

|

| 6. |

Attach engine to suitable engine overhaul stand

| • |

Attach KM-2358 to 3x engine transport

shackle

|

| • |

Raise using engine crane

|

| • |

Attach engine to engine overhaul stand

|

| • |

Detach KM-2358 from 3x engine

transport shackle

|

|

| 7. |

Drain engine oil

| • |

Place collecting basin underneath.

|

| • |

Remove oil filter housing cover

|

| • |

Remove oil filter element

|

|

| 8. |

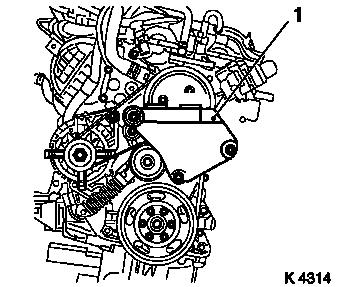

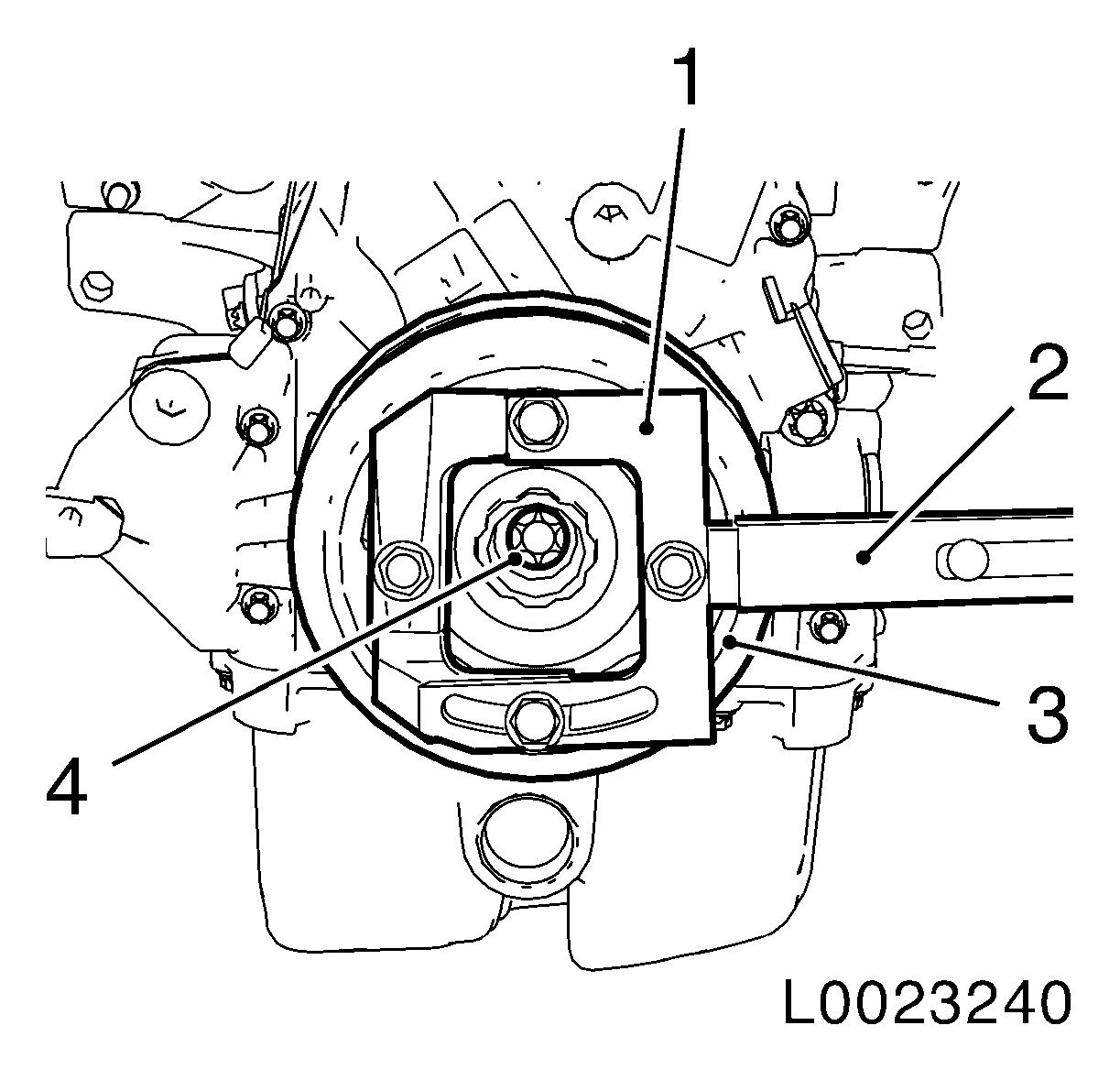

Remove engine bracket right (1)

|

| 9. |

Screw in oil drain bolt

|

|

|

| 10. |

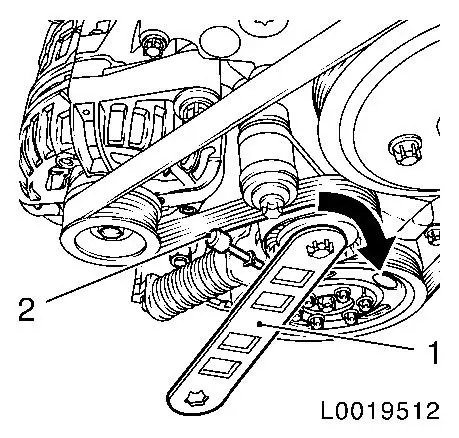

Detach ribbed V-belt

| • |

Mark direction of rotation

|

| • |

Tension the ribbed V-belt tensioner using KM-6131 (1) in the direction of the arrow

|

| • |

Release ribbed V-belt tensioner

|

|

|

|

| 11. |

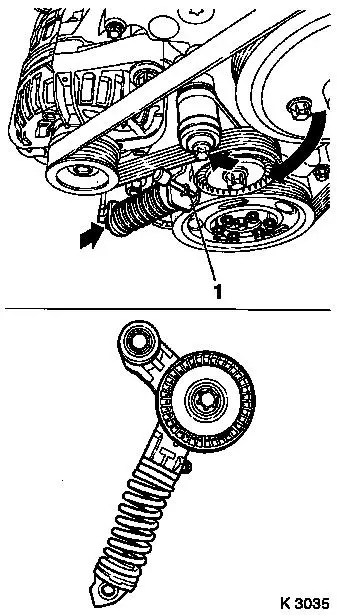

Remove ribbed V-belt tensioner

| • |

Unscrew 2 bolts (arrows)

|

| • |

Remove ribbed V-belt tensioner

|

|

|

|

| 12. |

Detach coolant pump ribbed V-belt pulley

| • |

Unscrew 3x bolts

Note: Counterhold with

open-end wrench

|

|

| 13. |

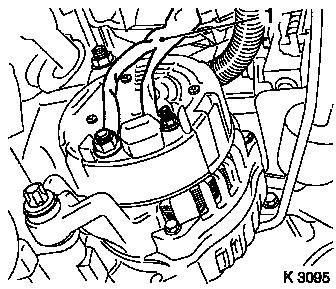

Detach alternator

| • |

Detach alternator wiring harness (1)

|

| • |

Detach 2x bolted connections

|

|

|

|

| 14. |

Detach 3x coolant hoses from coolant pump

|

| 15. |

Unclip engine management wiring harness from cylinder head

cover

| • |

Disconnect 3 wiring harness plugs

| – |

Camshaft sensor, coolant temperature sensor, oil pressure

sensor

|

|

|

| 16. |

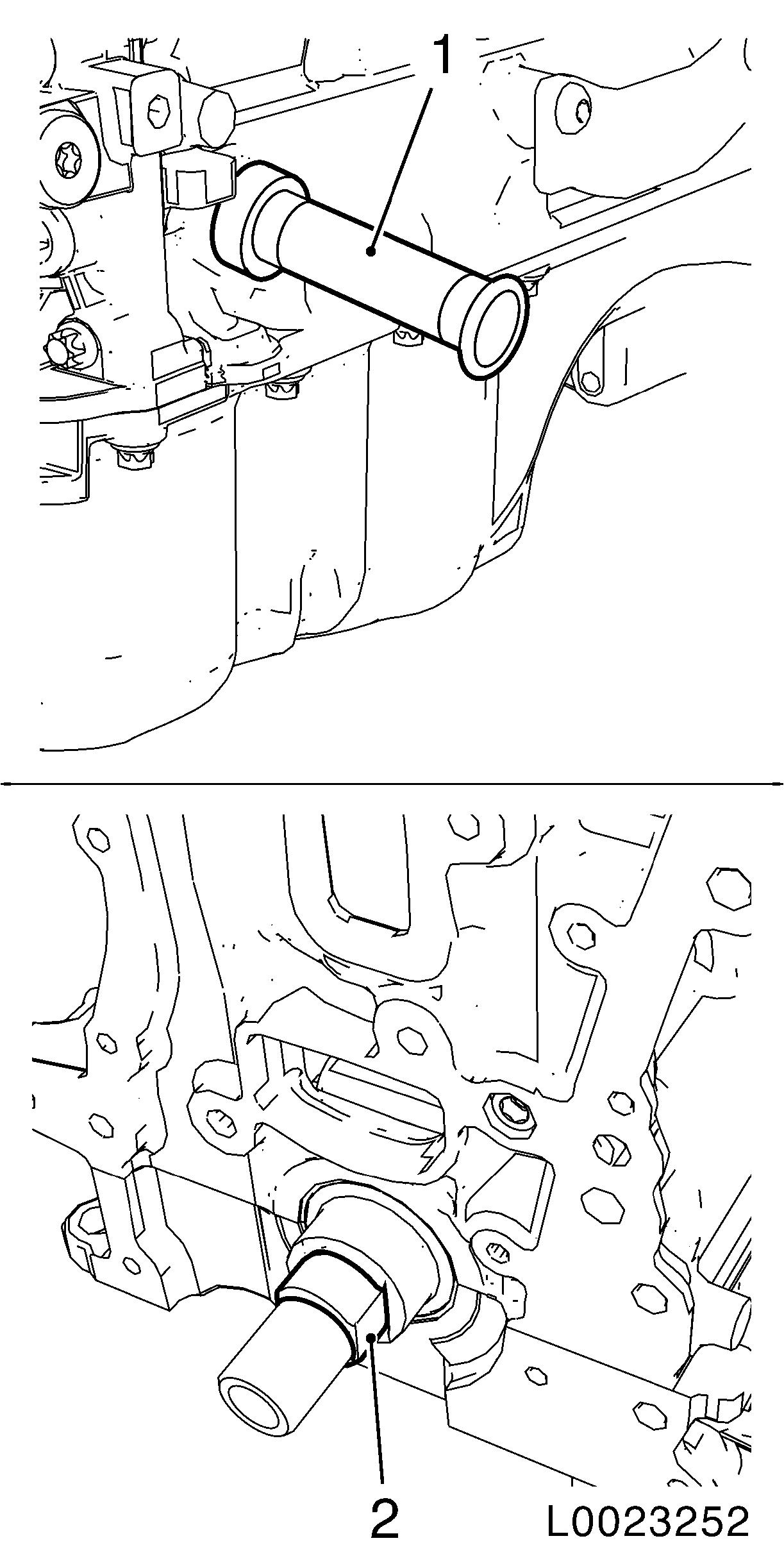

Detach coolant pump (1) together with thermostat housing

Note: When removing

guide sleeves, please note

| • |

Place collecting basin underneath.

|

| • |

Unscrew 9x bolts

Note: Note differing

bolt lengths (arrows = short bolts)

|

|

|

|

| 17. |

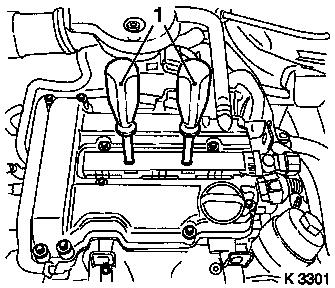

Detach ignition module

| • |

Detach ignition module cover

|

| • |

Disconnect ignition module wiring harness plug

|

| • |

Pull out using KM-6009 (1)

Note: Do not tilt

|

|

|

|

| 18. |

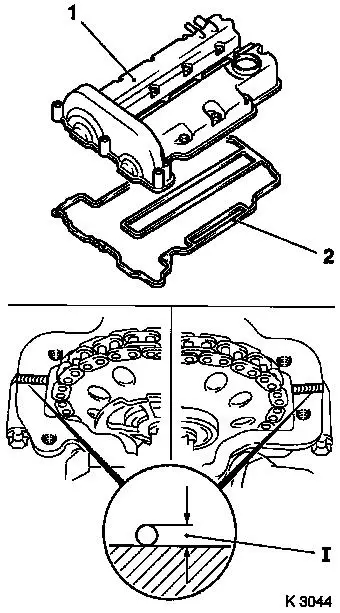

Remove cylinder head cover

| • |

Detach 2 engine vent hoses

|

|

|

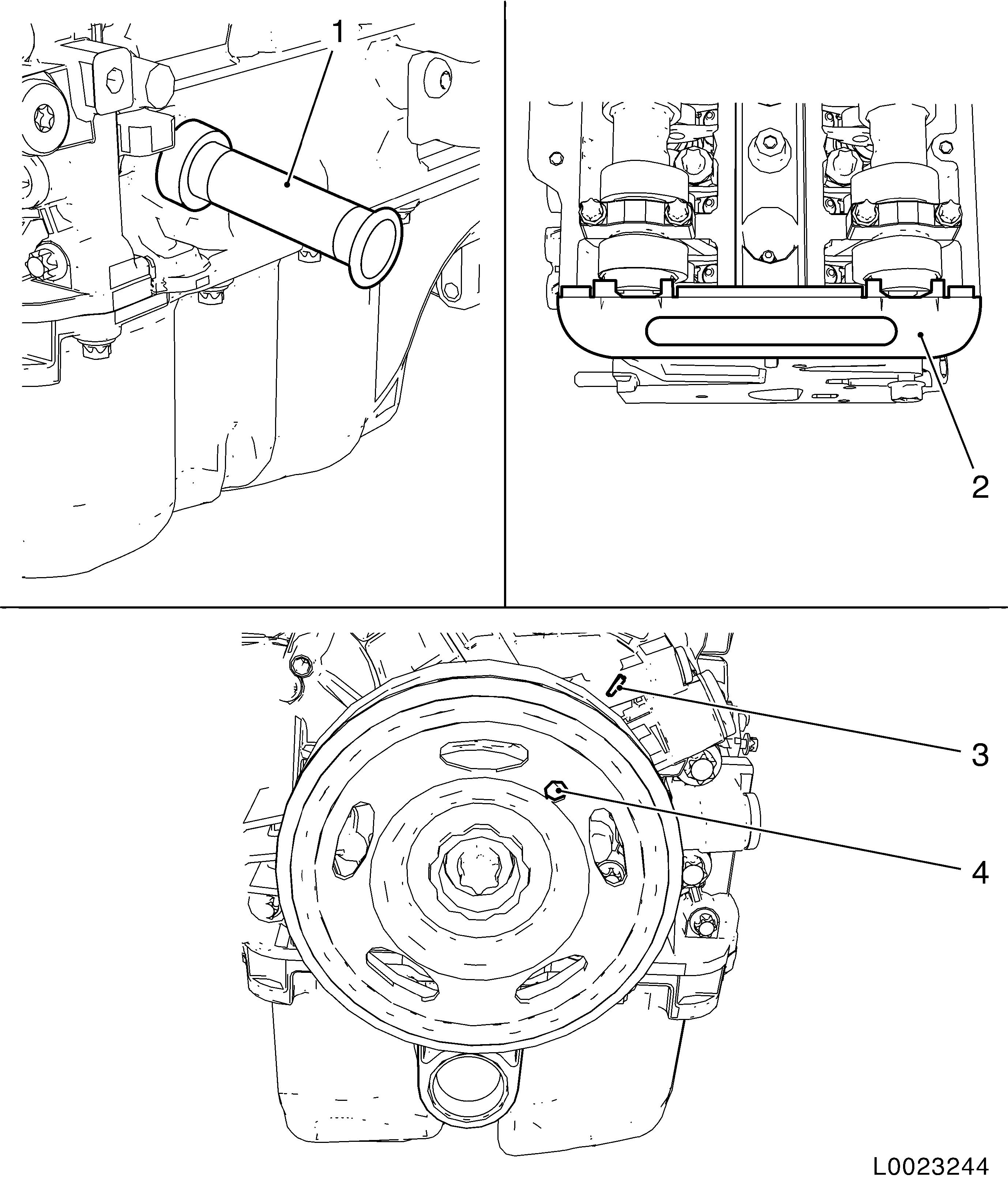

| 19. |

Set engine to TDC of combustion stroke of cylinder 1

| • |

Unscrew crankshaft closure bolt

|

| • |

Rotate crankshaft in direction of engine rotation to the

marking (4) on the torsional vibration damper and align with

marking (3) on timing case

|

Important: It must be possible to

insert EN-953 smoothly and without major

effort into the camshaft grooves.

|

| • |

Lock camshafts with EN-953 (2)

|

Important: It must be possible to

insert KM-952 smoothly and without major

effort into the crankshaft recess.

|

| • |

Fix crankshaft with KM-952 (1)

|

|

|

| 20. |

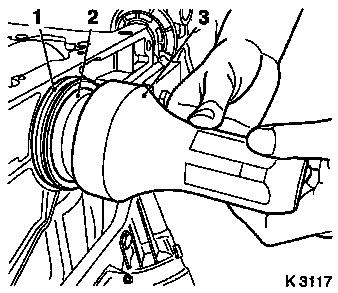

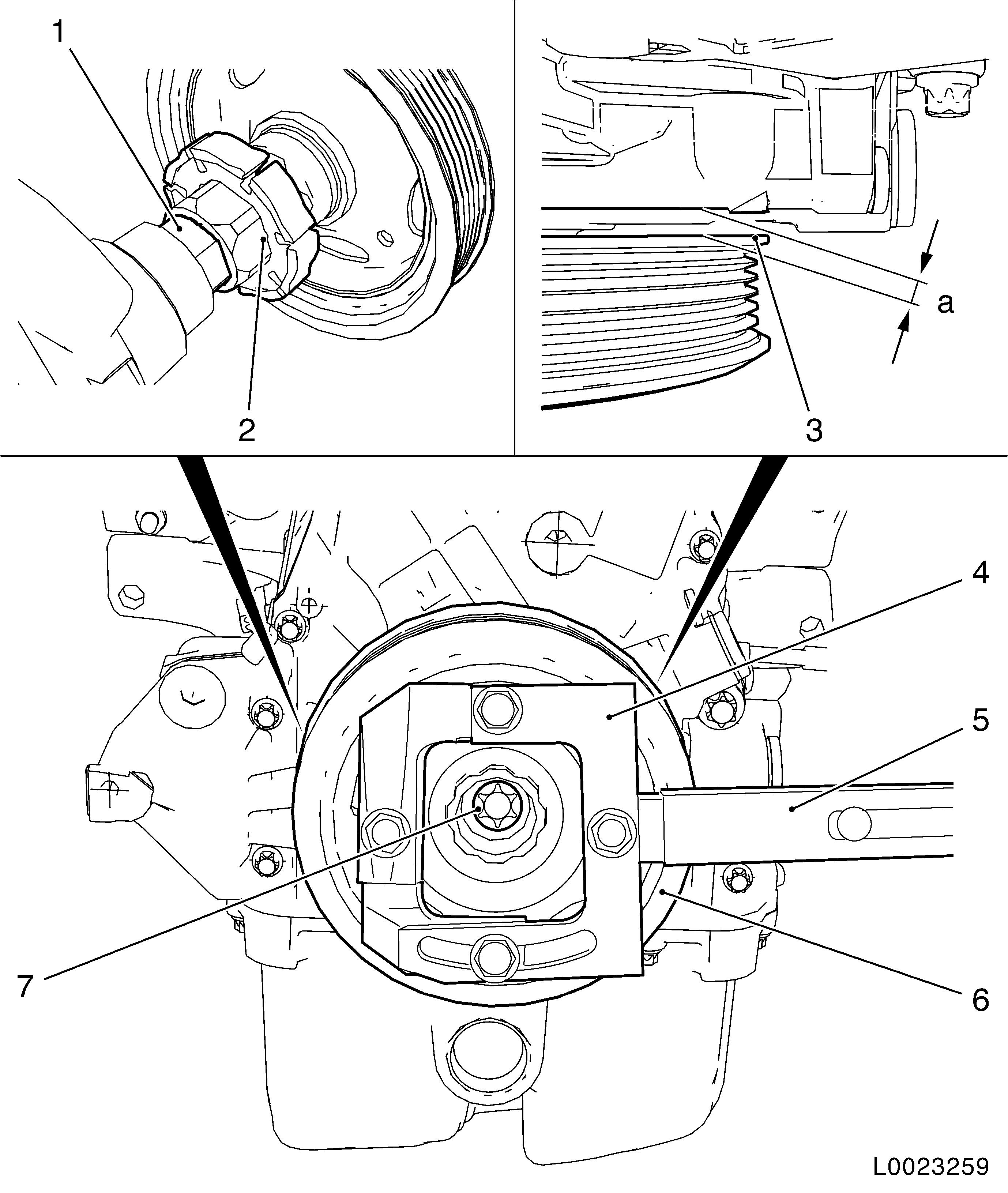

Detach torsional vibration damper (3)

| • |

Counterhold it with EN-49979 (1)

together with KM-956-1 (2)

|

|

|

|

| 21. |

Rotate engine on engine overhaul stand through 180°

|

| 22. |

Remove oil pan

Important: Do not damage oil pan

and base place seal surfaces when prising off

|

| • |

Detach oil pan by carefully prising out to position (1)

|

|

|

|

| 23. |

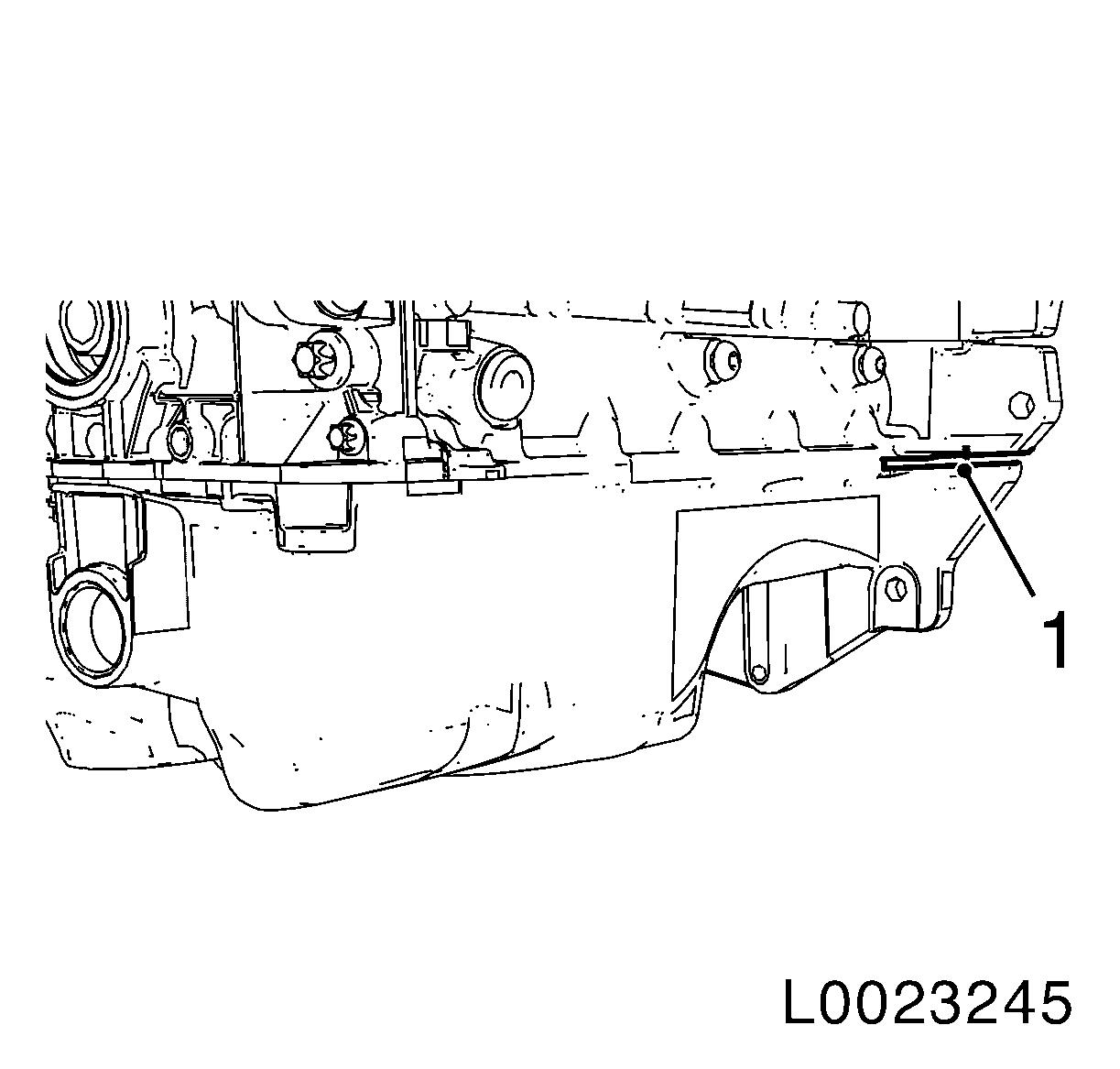

Detach oil baffle plate

|

| 24. |

Rotate engine on engine overhaul stand through 180°

|

|

| 25. |

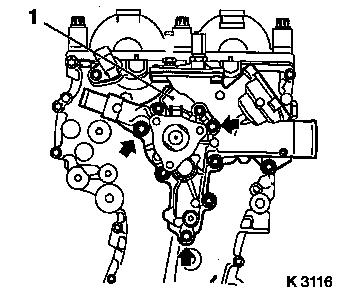

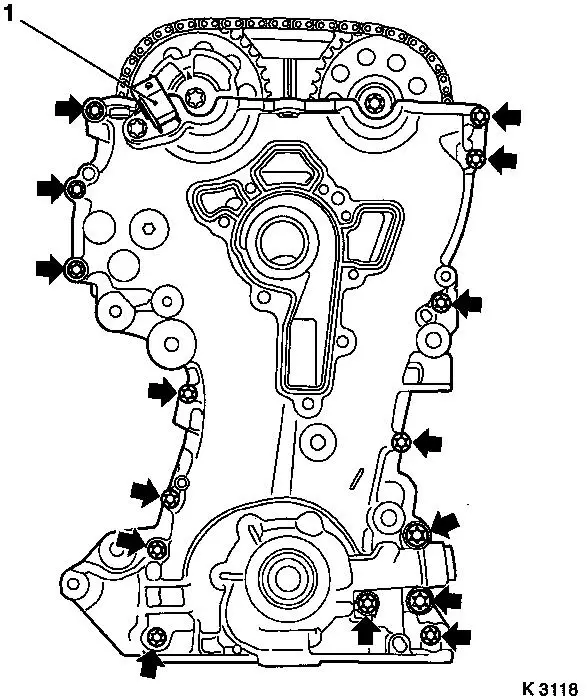

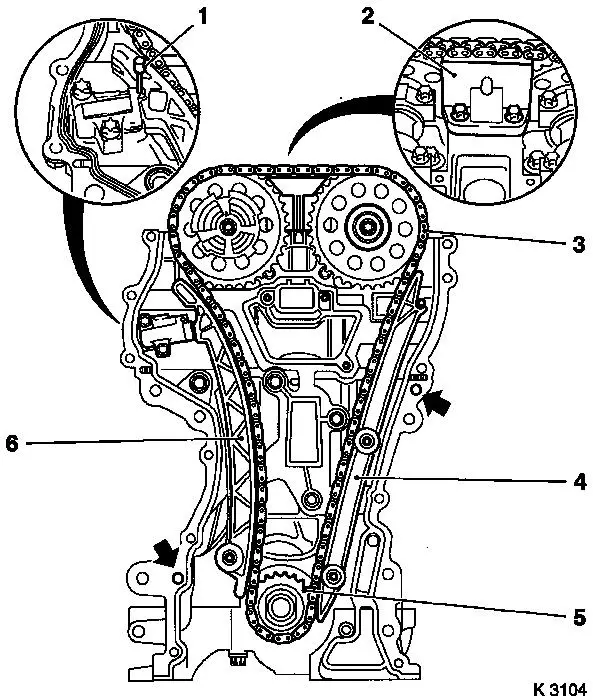

Remove timing case

| • |

Unscrew 15x bolts (arrows)

| – |

Do not damage camshaft sensor (1)

|

|

| • |

Prise out timing case seal ring

Note: Do not damage

sealing surface

|

|

|

|

| 26. |

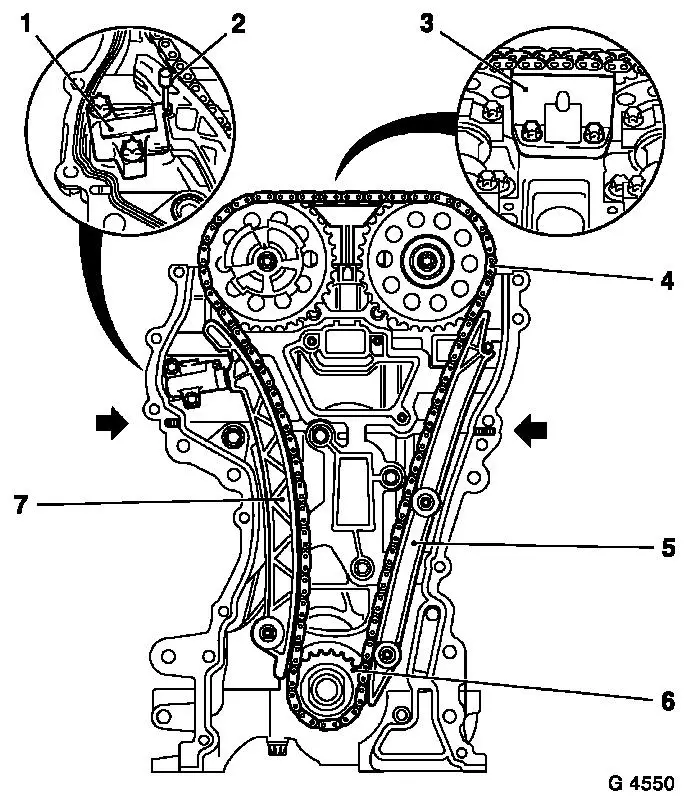

Detach chain drive

| • |

Slacken bolts, camshaft sprockets

| – |

Counterhold the camshafts on the hexagon

|

|

| • |

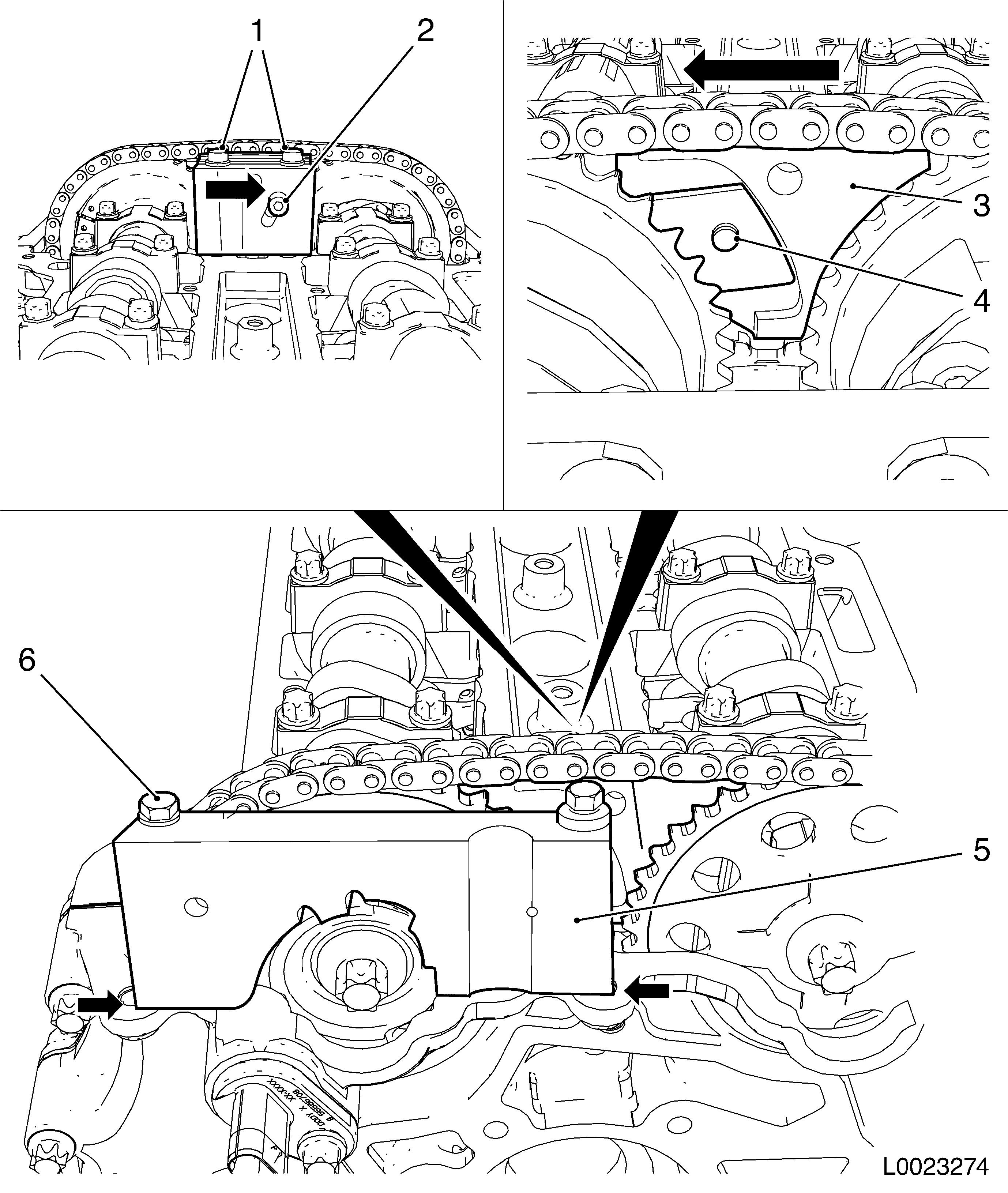

Lock chain tensioner (1)

|

|

| 27. |

Turn back chain tensioner (1) and lock with KM-955-1 (2)

|

| 28. |

Remove sliding rail (3)

|

| 29. |

Remove guide rail (5)

|

| 30. |

Remove guide rail (7)

|

| 31. |

Remove timing chain (4), drive gear (6) and timing case

gasket

|

|

| 32. |

Rotate engine on engine overhaul stand through 180°

|

| 34. |

Remove crankshaft sensor

Note: Note seal

ring

|

| 35. |

Detach cylinder block base plate

|

| 36. |

Remove con-rod bearing cover

Note: The shear

surfaces of the con-rod and the con-rod bearing cover form a unique

fit and must not be swapped or damaged. Do not lay down on the

shear surfaces

| • |

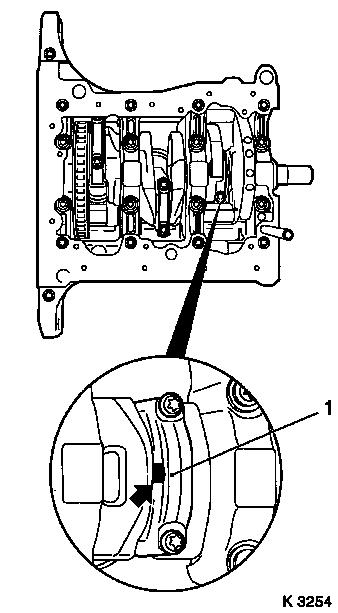

Mark con-rod bearing cap (1)

|

| • |

Remove con-rod bearing cap

|

|

|

|

| 37. |

Detach crankshaft

| • |

Remove rear crankshaft seal ring

|

| • |

Take out crankshaft and place on wooden blocks

|

|

| 38. |

Remove crankshaft bearing clips

| • |

Mark crankshaft bearing shells

Note: Observe the

correct sequence

|

|

| 39. |

Remove con-rod bearing shells

| • |

Identify con-rod bearing shells

Note: Observe the

correct sequence

|

|

| 40. |

Check all parts for wear, replace if necessary

|

| 41. |

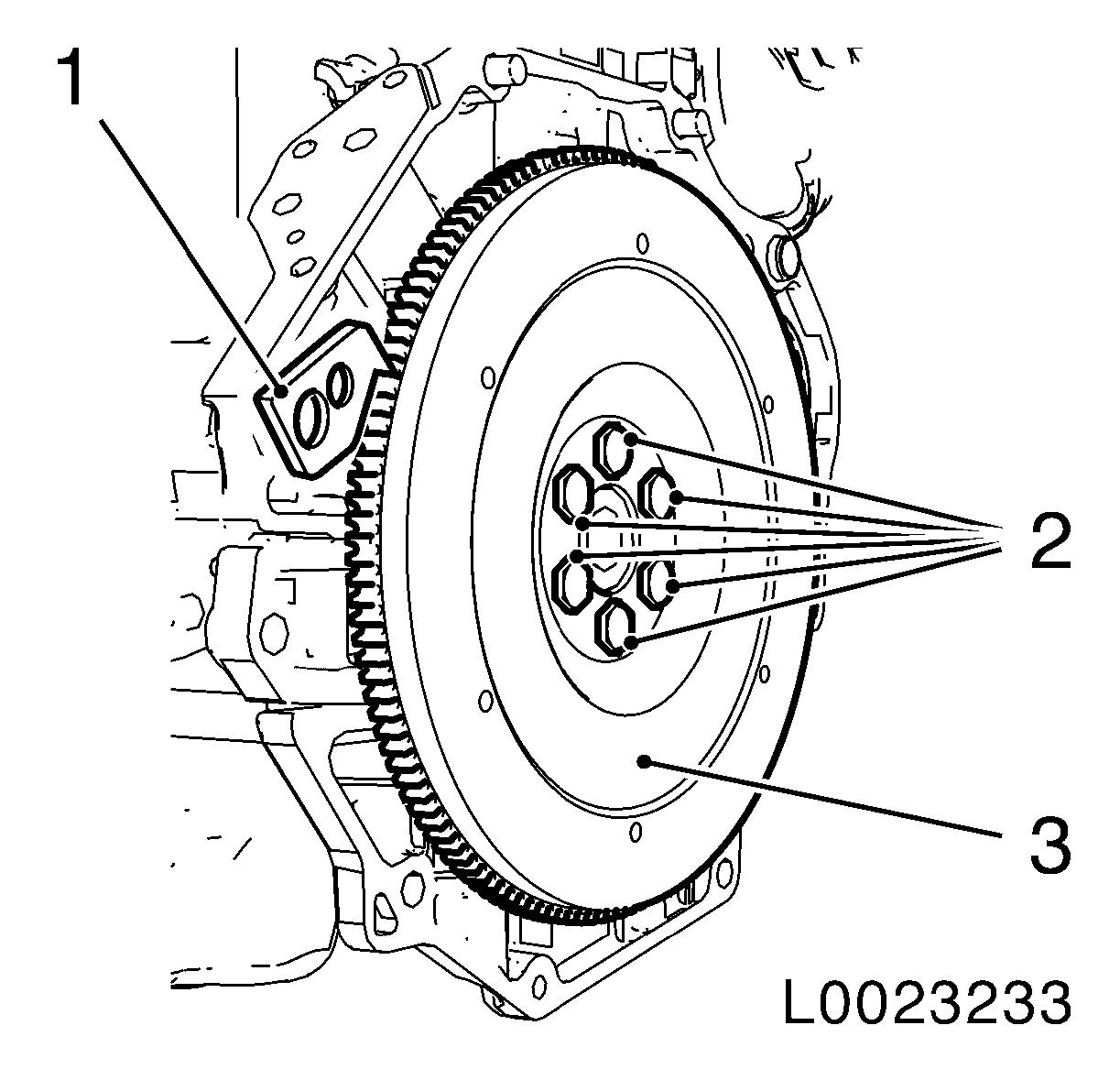

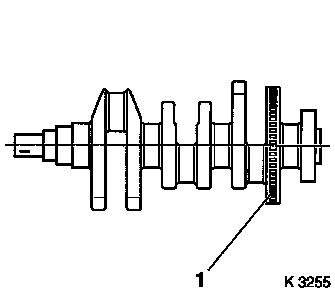

Detach crankshaft pulse sensor disk (1)

|

|

|

Install

Install

| 42. |

Attach crankshaft pulse pick-up disc

|

| 43. |

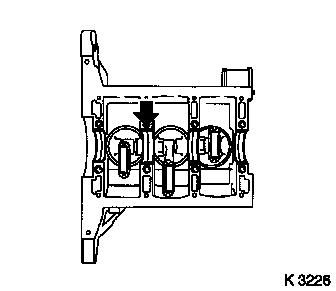

Insert crankshaft bearing shells in cylinder block and in

cylinder block base plate

| • |

Note position of axial bearing (arrow)

|

|

|

|

| 44. |

Insert con-rod bearing shells into con-rods and con-rod bearing

caps

|

| 45. |

Insert crankshaft carefully into cylinder block

Note: The position of

the crankshaft can be corrected by hammering gently on the crank

webs with a rubber mallet

| • |

Coat crankshaft journal with engine oil

|

|

| 46. |

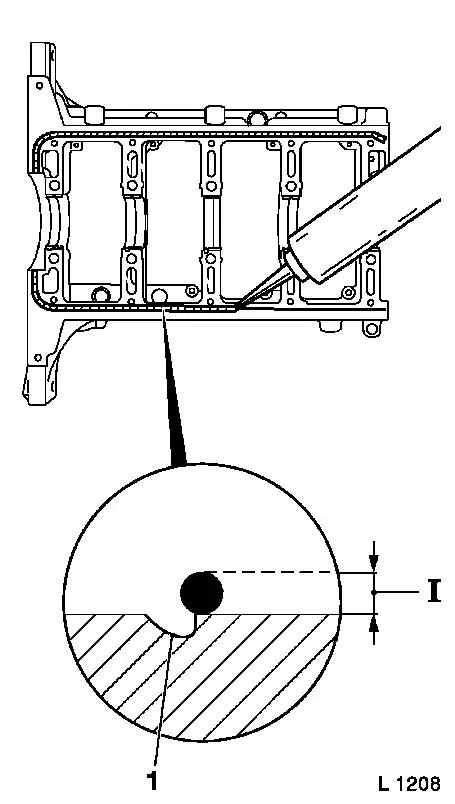

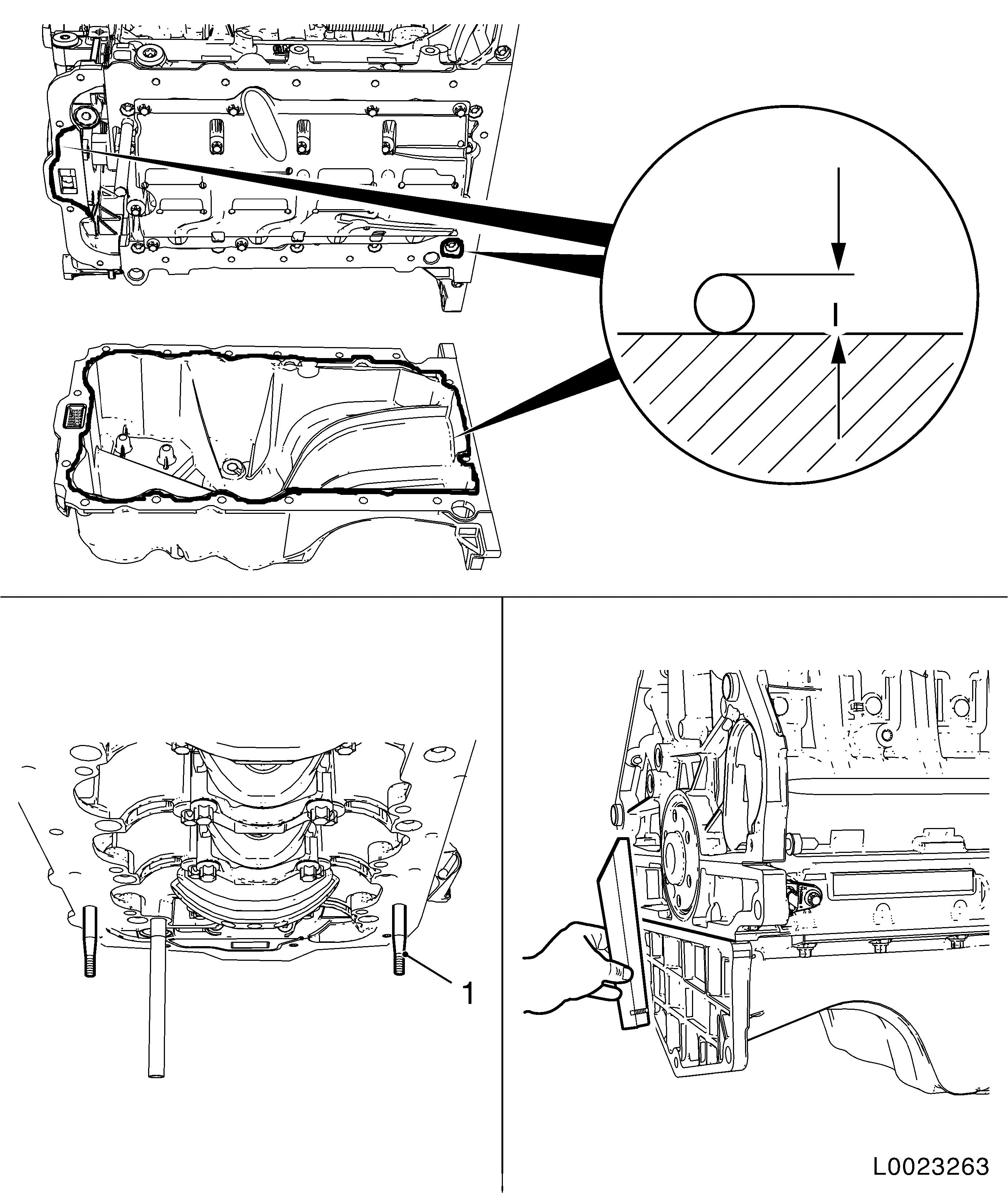

Attach cylinder block base plate to cylinder block with new

bolts

Note: Complete assembly

work within 10 minutes

| • |

Apply sealant to the outer edge of the groove (dimension I = 2

mm)

Note: Do not apply

sealant in groove

|

Important: Observe tightening

sequence

|

| • |

Tighten 8 M8 bolts inside 25 Nm +

60° + 15°

|

| • |

Tighten 10 M6 bolts outside 10 Nm +

60° + 15°

|

| • |

Remove superfluous sealant

|

|

|

|

| 47. |

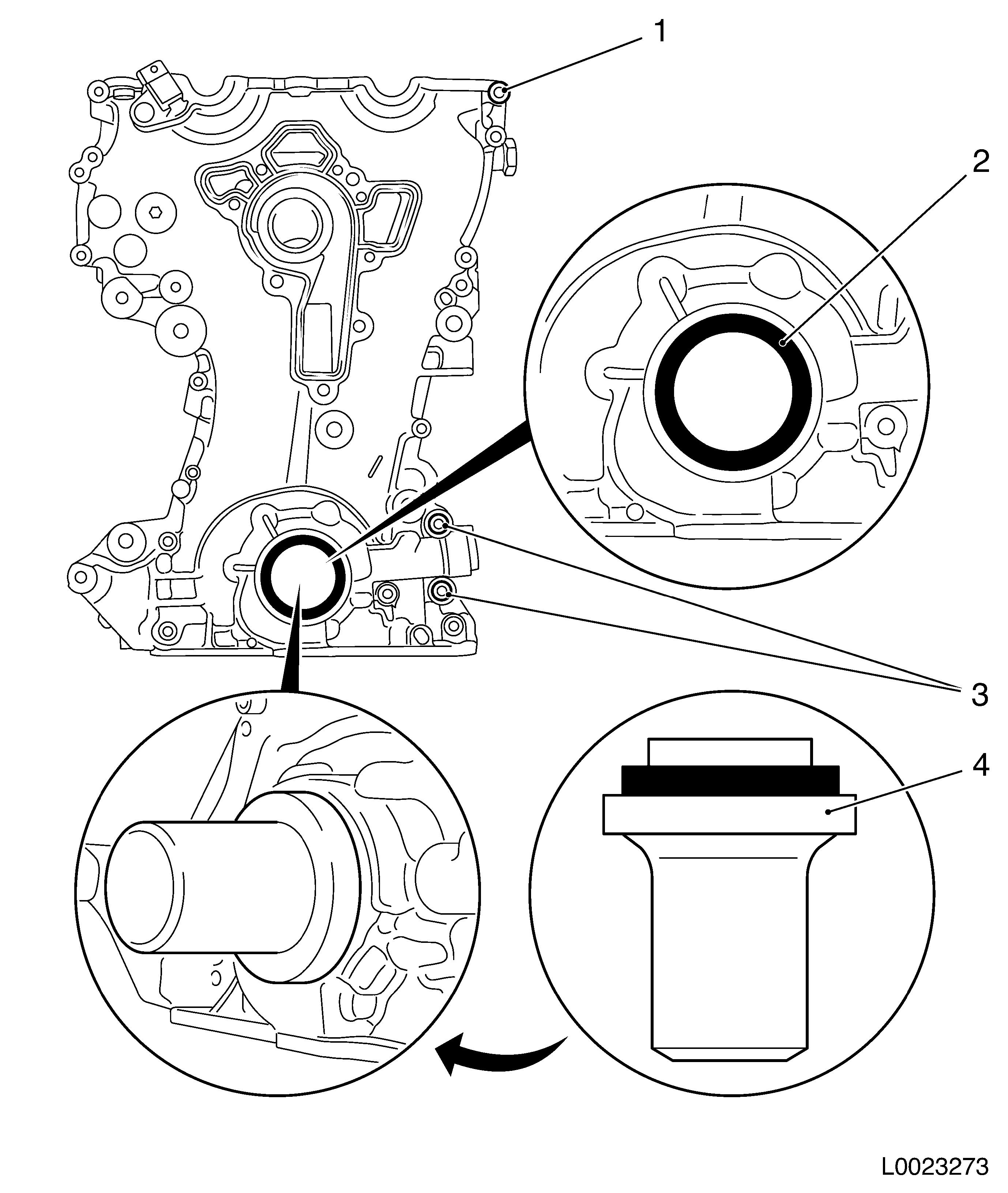

Install crankshaft rear seal ring (1)

| • |

Position KM-235-6 (2) on crankshaft

journal

|

| • |

Slide seal ring onto KM-235-6

|

| • |

Drive in flush using KM-658-1 (3)

|

|

|

|

| 48. |

Attach con-rod bearing cap to con-rod with new bolts

Note: Note installation

position, bead (arrow) on the con-rod bearing cap points towards

the transmission side

| • |

Tighten 6 bolts 13 Nm + 60° +

15°

Note: Only use screws

of size M6.5

|

|

|

| 49. |

Lock crankshaft

| • |

Unscrew crankshaft closure bolt

|

Important: It must be possible to

insert KM-952 smoothly and without major

effort into the crankshaft recess.

|

| • |

Insert KM-952 (1)

| – |

Rotate smoothly on crankshaft dihedral (2) in direction of

engine rotation until KM-952 engages

|

|

|

|

| 50. |

Attach crankshaft sensor

Note: Use new seal

ring

| • |

Fix wiring harness plug

|

|

|

| 51. |

Replace timing case gasket

| • |

Apply 2x sealing bead as shown (2 mm)

Note: After application

of the sealant, the chain drive and timing case must be fitted

within 10 minutes

|

| • |

Place new gasket in position

Note: Note guide

bushings (arrows)

|

|

| 52. |

Attach timing chain

| • |

Insert KM-953 into camshafts

Note: If necessary,

gently adjust camshafts by the hex

|

| • |

Apply timing chain (3) together with drive gear (5)

|

|

| 53. |

Attach timing chain tension rail (6)

| • |

Tighten bolt 20 Nm

Note: Ensure correct

seat of timing chain

|

|

| 54. |

Attach timing chain guide rail (4)

| • |

Tighten 2x bolt 8 Nm

Note: Ensure correct

seat of timing chain

|

|

| 55. |

Attach timing chain sliding rail (2)

|

| 56. |

Relieve tension on chain tensioner

|

|

|

| 57. |

Attach timing case.

Note: Note guide

bushings and camshaft sensor

| • |

Tighten 13x bolt M6 (1) 8 Nm

|

| • |

Tighten 2x M10 bolt (3) 35 Nm

|

|

| 58. |

Replace front crankshaft sealing ring (2)

| • |

Drive in flush using KM-960

|

|

|

|

| 59. |

Fit torsional vibration damper (6)

| • |

Insert torsional vibration damper in oil pump rotor hex head

(2) and crankshaft dihedral (1)

Note: Marking on the

torsional vibration damper must align with the marking on the

timing case

|

| • |

Check for correct torsional vibration damper seating

| – |

Measure distance between torsional vibration damper and edge of

timing case (dimension a = 5,5 mm)

|

|

| • |

Screw in torsional vibration damper bolt (7)

|

| • |

Tighten torsional vibration damper bolt 150 Nm

| – |

Counterhold it with EN-49979 (4)

together with KM-956-1 (5)

|

|

|

|

| 60. |

Fix 2x camshaft sprocket

| • |

Attach EN-49977-200 (3)

Note: Press EN-49977-200 in direction of arrow so that the

teeth (4) engage in the teeth of the intake camshaft sprocket

without play

| – |

Tighten 2x fastening bolt (1)

|

| – |

Tighten adjusting bolt (2)

Note: Press EN-49977-200 in direction of arrow when

tightening

|

|

|

| 61. |

Adjust and fix phase sensor disc

| • |

Rotate phase sensor disc until EN-49978 (5) can be inserted

Note: EN-49978 must rest on the surfaces shown (arrows)

without play

|

| • |

Tighten 2x fastening bolt (6)

|

|

| 62. |

Tighten 2x camshaft sprocket 50 Nm +

60°

| • |

Counterhold with open-end wrench against the hexagon of the

camshafts

|

|

| 63. |

Remove all special tools: KM-952 ,

EN-953 , EN-49977-200 , EN-49978

|

|

|

| 65. |

Repeat adjustment procedure if necessary

|

| 66. |

Remove locking tool

| • |

KM-952 , KM-953 , EN-49978

|

|

| 67. |

Insert crankshaft sealing plug and tighten 50 Nm

Note: Use new seal

ring

|

| 68. |

Attach coolant pump together with thermostat housing

| • |

Insert 9x bolt 8 Nm

Note: Note different

bolt lengths

|

|

| 69. |

Attach 3 coolant hoses to coolant pump

|

| 70. |

Clip engine management wiring harness into cylinder head

cover

| • |

Connect 3 wiring harness plugs

| – |

Camshaft sensor, coolant temperature sensor, oil pressure

sensor

|

|

|

| 71. |

Attach coolant pump belt pulley

| • |

Insert 3x bolt and tighten 22 Nm

Note: Counterhold with

open-end wrench on flange

|

|

| 72. |

Rotate engine on engine overhaul stand through 180°

|

| 73. |

Attach oil baffle plate

|

|

| 74. |

67. Install oil pan

| • |

Apply sealant (dimension I = 2 mm)

Note: Oil pan

installation must take place within 10 minutes

| – |

For the bolt hole shown

|

|

| • |

Rotate 2x EN-49980 (1) into the

positions shown

|

Important: When positioning the

oil pan, it is necessary to ensure that the sealing bead is not

wiped away.

|

| • |

Carefully apply the oil pan

Note: Pass EN-49980 through corresponding bolt holes

|

| • |

Insert 4x bolt, offset diagonally

|

| • |

Adjust oil pan with rubber mallet and straightedge

Note: Straightedge must

rest on the oil pan and cylinder block without play

|

|

|

| 75. |

Rotate engine on engine overhaul stand through 180°

|

| 76. |

Attach cylinder head cover (1)

| • |

Apply sealant (dimension I = 2 mm)

Note: Complete assembly

work within 10 minutes

|

| • |

Attach 2x engine vent hose

|

|

| 77. |

Attach ignition module

| • |

Connect ignition module wiring harness

|

|

|

|

| 78. |

Install alternator

| • |

Insert alternator into bracket

|

| • |

Attach 2x screwed connection 35

Nm

|

| • |

Attach alternator wiring harness

|

|

| 79. |

Attach ribbed V-belt tensioner -

| • |

Tighten bolt (M8) 20 Nm

|

| • |

Tighten bolt (M10) 55 Nm

|

|

| 80. |

Insert ribbed V-belt

Note: Ensure correct

running direction and installation position

| • |

Release ribbed V-belt tensioner

|

|

| 81. |

Attach engine bracket right

|

| 82. |

Top up engine oil.

| • |

Observe specified engine oil quantity

|

|

| 83. |

Detach engine from engine overhaul stand

| • |

Attach KM-2358 to 3x engine transport

shackle

|

| • |

Hitch engine up to workshop crane.

|

| • |

Lower engine onto wooden pallet

|

| • |

Detach KM-2358 from 3x engine

transport shackle

|

|

| 84. |

Fit flywheel

| • |

Clean 6x thread in crankshaft

|

| • |

Tighten 6x new bolt 35 Nm +60

°

|

|

| 85. |

Attach clutch and thrust plate

|

| 86. |

Attach manual transmission to engine

|

|