Subject:

Removal

and Installation of Directly Adhered Glass Screens in Service

Vehicles:

All

except Frontera, Monterey, Campo

General:

The

adhesive technology in production has been developed with the use of the most

modern adhesive and glass installation systems.

At

the same time, the number of glass screens with PU trim strips in the

Vectra/Cavalier, Calibra and Tigra has been increased.

In

the Service sphere, the oscillating cutter, the protective hose and the insert

awl for the wire cutter set have been introduced into the delivery range.

This Technical Information

Bulletin offers a recap of the most important points for guaranteeing

non-destructive removal of glass screens. This Technical Information Bulletin

does not replace the information in the Service Instructions which must also be

observed.

|

Operations - Quick Overview

Areas

of Application

Service

Literature

Service

Instructions,

Technical

Information Bulletins

Materials,

Products, Tools

Positioning

(Cutting Wires)

Wire

Lengths/Application/Cutting

Application

of Protective Hose

Application

of Thermoknife

Application

of Oscillating Cutter

PU

Activator

Application

of Adhesive

Bond

Parts

Tensioning

Belts

Waiting

Periods

Environmental

Protection/Disposal

|

|

|

Operations - Details

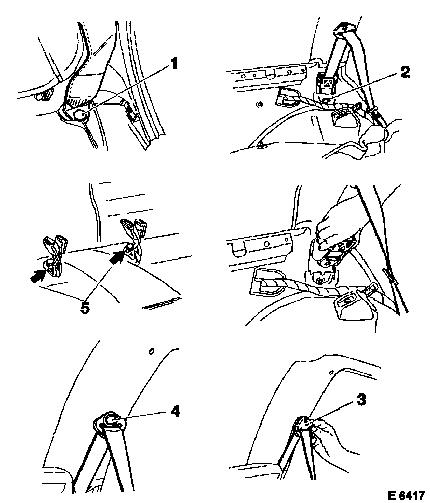

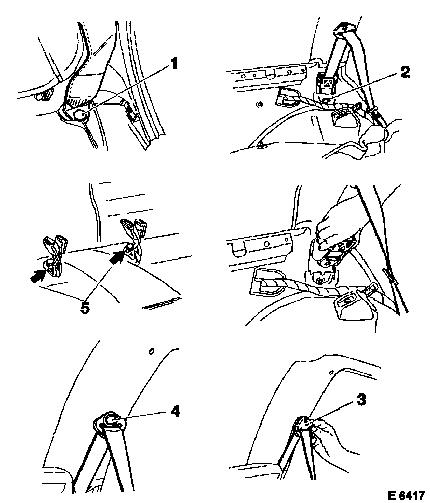

Areas of Application

All

directly adhered glass screens (example: Corsa-B, Tigra)

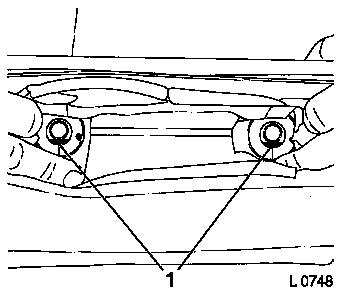

Windscreen

(1)

Rear

screen / tailgate screen (2)

Side

windows (3)

Does

not apply for bolted or rail-mounted screens

|

|

|

Service-Literatur

Service Literature

1 Existing

Technical Information Bulletins

2 Brochures

(e.g. New Technical Features for new product features)

3 Service

Instructions

Vehicle-specific

operations and instructions

|

|

|

Materials, Products, Tools

From

the "Special Service Tools" catalogue:

Wire

Cutter Set MKM-589-B (with protective hose and insert awl)

Thermoknife

Set MKM-590-B

Tensioning

Belts MKM-591

Window

Screen Suction Lifter MKM-641

Oscillating

Cutter1)

MKM-846-1E

(electric) or

MKM-846-1P

(pneumatic)

Knife

Set, Tailgate Screen, Tigra2)

MKM-846-50

Knife

Set, Windscreen, Tigra2)

MKM-846-60

Scraper

Set2) MKM-846-70

Assembly

Tool Set, Tigra MKM-848

1) Always specify when ordering

E = electric P = pneumatic

2) Suitable for MKM-846-1E and MKM-846-1P

|

|

|

|

|

Allocation

of permissible special service tools to individual screens and vehicle types

|

Type

|

Windscreen

|

Rear screen

|

Tailgate screen

|

Side screens

|

|

Kadett-D/

Astra-D

|

-

|

-

|

Wire

|

-

|

|

Ascona-C

|

-

|

-

|

Wire/osc. cutter*)

|

-

|

|

Kadett-E/

Astra/ Belmont

|

Wire/thermoknife/ osc. cutter*)

|

Wire1)/thermoknife1)/ osc. cutter*)1)

|

Wire1)/thermoknife1)/ osc. cutter*)1)

|

Wire1)/thermoknife1)/ osc. cutter*)1)

|

|

Astra-F

|

Wire/thermoknife/ osc. cutter*)

|

Wire2)/thermoknife2)/ osc. cutter*)2)

|

Wire/thermoknife/ osc. cutter*)

|

-

|

|

Corsa-B

|

thermoknife/ osc. cutter*)

|

-

|

Wire/thermoknife/ osc. cutter*)

|

Wire3)/thermoknife3)

|

|

Vectra/

Cavalier

|

Wire/thermoknife/ osc. cutter*)

|

Wire/thermoknife/ osc. cutter*)

|

Wire4)/thermoknife/

osc. cutter*)

|

-

|

|

Calibra

|

thermoknife/ osc. cutter*)

|

-

|

Wire4)/osc.

cutter*)

|

-

|

|

Omega/

Carlton

|

thermoknife/ osc. cutter*)

|

Wire/thermoknife/ osc. cutter*)

|

Wire/thermoknife/ osc. cutter*)

|

-

|

|

Senator-B

|

thermoknife/ osc. cutter*)

|

Wire/thermoknife/ osc. cutter*)

|

Wire/thermoknife/ osc. cutter*)

|

-

|

|

Omega-B

|

thermoknife/ osc. cutter*)

|

Wire/thermoknife/ osc. cutter*)

|

thermoknife/ osc. cutter*)

|

-

|

|

Tigra

|

osc. cutter*)

|

-

|

osc. cutter*)

|

-

|

*) Oscillating cutter (electric or pneumatic)

1) Does not apply for Models 37, 38, 47, 48

(rubber-mounted glass screens)

2) Does not apply for Model 53-B

(rubber-mounted glass screens)

3) Does not apply for Models 71 (bolted

swing-out window), 78, 79 (bolted window)

4) Use only with protective hose (Wire Cutter

Set MKM - 589 - B)

Adhesives

(Parts and Accessories Delivery Range)

1-component

Screen Adhesive - 310 ml

2-component

Screen Adhesive Set - 310 ml

Processing

with mixer rod.

2-component

Screen Adhesive Set - 2 x 225 ml

Processing

with electric pistol Betagun 2000 and forced mixture.

Note:

The

adhesives are based on polyurethane (PU).

1-component

screen adhesives cure physically on application of oxygen and air

humidity.

2-component

screen adhesives are fast-reacting chemical systems. Curing occurs without

the influence of air humidity.

Always

check the date of expiry before using adhesives.

|

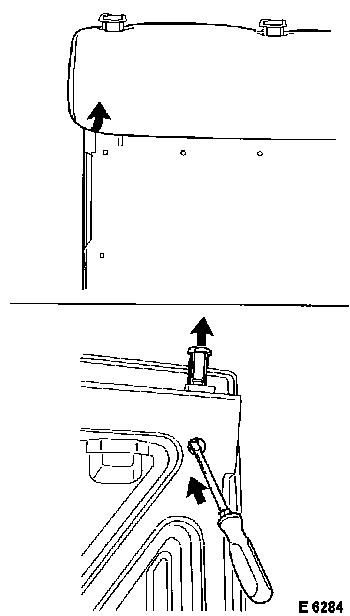

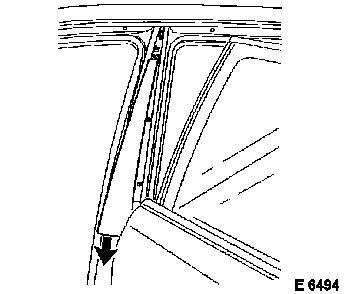

Positioning (Cutting Wire)

General

Two

technicians are required (to avoid damage)

Wear

protective gloves and goggles.

Do

not use cutting agents and/or lubricants.

Cutting

agents and/or lubricants always lead to a loss of adhesion when the screen is

installed.

Remove

attaching parts as specified in Service Instructions.

|

|

|

Screens without PU Trim Strips

All

screens approved for wire (table, see page 7), except tailgate screen for

Vectra/Cavalier and Calibra

Use

square wire (MKM - 589 - 1)

Wear

protective goggles

Wear

safety gloves

Maximum

wire length 600 mm/24 in.

Guide

cutting wire through adhesive bed from inside outwards Use protective

hose to avoid damage

|

|

|

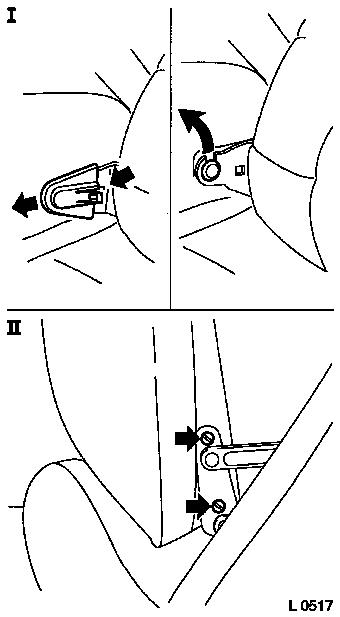

Screens with PU Trim Strips

Vectra/Cavalier

and Calibra

Tailgate

screen

Construct

ad hoc tool for drill bit:

welding

rod Ø 3 mm/0.12 in., 90 mm/3.5 in. long, grind to a point

Slide

ad hoc tool under trim strip from outside at point shown (A), tilt drill by

90° (parallel to glass surface)

Drill

wire application hole from outside inwards (B)

Use

protective hose from MKM-589-B.

Pull

cutting wire through drilled hole to inside

Wire

length 600 mm/24 in.

|

|

|

Wire Lengths/Application/Cutting

General

Position: Wire length:

windscreen,

rear 600 mm/24 in.

screen

and tailgate

screen,

side

Windscreen, 1200

to

rear

screen and 1400 mm/

tailgate

screen, 48 to 55 in.

upper and lower

Side

windows 600 mm/24 in.

Always

use protective hose (MKM-589-4)

Screens without PU Trim Strips

All

screens approved for wire (see table page 7), except tailgate screen for

Calibra and Vectra/Cavalier

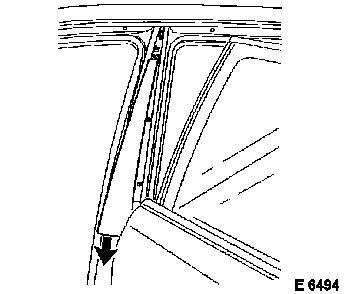

Pull

cutting wire flat to the edge of the glass on the outside and keep under

tension.

Cut

on inside.

Avoid

damage to the moulded headlining and upholstery in the interior.

Guide

handle on inside close to the screen.

Cut

to the corner of the screen, then change wire.

Apply

corrosion protection if necessary.

|

|

|

Screens with PU Trim Strips

Calibra

Tailgate

screen with PU trim strip.

Use

protective hose (MKM-589-4)

Cut

at side:

Route

cutting wire on outside under lip of trim strip (A) and guide along

adhesive bead.

Keep

cutting wire under tension on outside.

Always cut on the inside

(B).

Cut

to the corner of the screen, then change wire.

|

|

|

Cutting

at top and bottom:

Maximum

wire length 1400 mm/ 55 in.

Apply

cutting wire and protective hose at corner of screen (A) and apply under lip

of trim strip using insert awl (B).

Keep

cutting wire under tension on outside.

|

|

|

Cut

on inside.

Keep

cutting wire horizontal under tension on outside. Cut to corner of screen,

then change wire.

Apply

corrosion protection if necessary.

|

|

|

Screens with PU Trims Strips (Additional Adhesive Trim Strip Ends)

Vectra/Cavalier

Tailgate

screen with PU trim strip.

Cut

at sides:

Operation

see page 12.

Cut

at bottom:

Operation

see page 13.

Cut

at top:

Heat

up trim strip ends with foil adhesive (hot air dryer) and detach from body.

Route

cutting wire under ends of trim strip.

Wire

application and cutting see page 13.

Apply

corrosion protection if necessary.

Adhere

trim strip ends with sealing compound, alternatively with glue

|

|

|

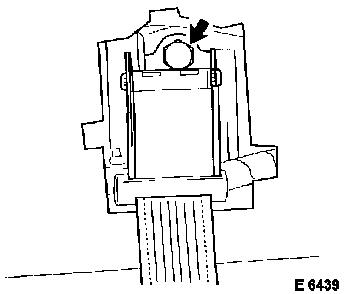

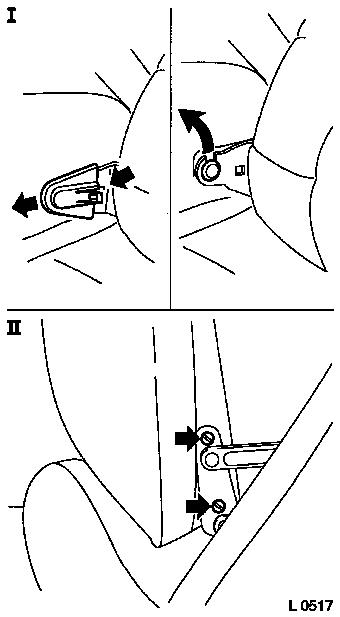

Application of Protective Hose

To

prevent paint damage and damage to the PU trim strips, use Protective Hose

MKM-589-4.

Guide

protective hose over cutting wire.

Guide

free end of cutting wire through adhesive bed

Route

protective hose with insert awl under lip of trim strip.

Cut

as described in previous section

Note:

Protective

hose will be likewise cut through and must not be reused.

|

|

|

Application of Thermoknife

All

screens approved for thermoknife (table page 7).

Ensure

adequate ventilation of workplace.

Use

prescribed cutting knife (Service Instructions).

Note

cutting direction, as specified in operating instructions.

Recut

remains of adhesive bead to thickness of approx. 1 mm/0.04 in.

Apply

corrosion protection if necessary.

|

|

|

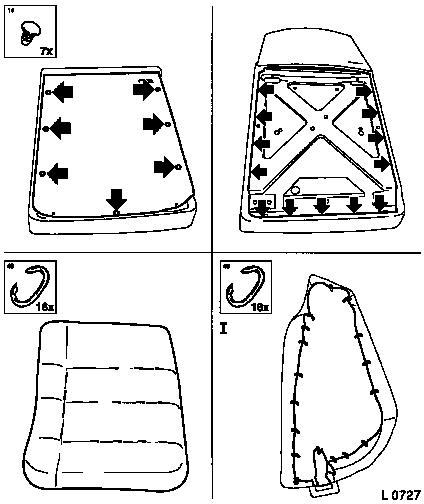

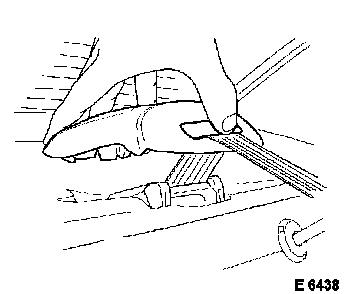

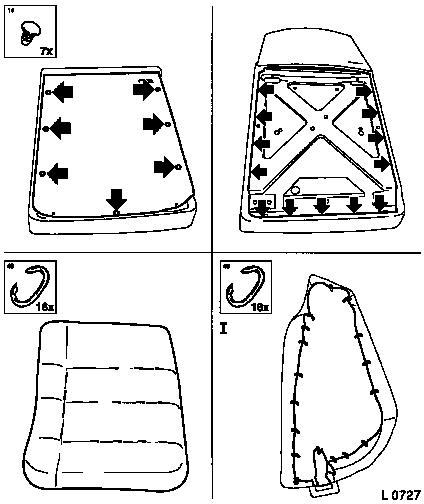

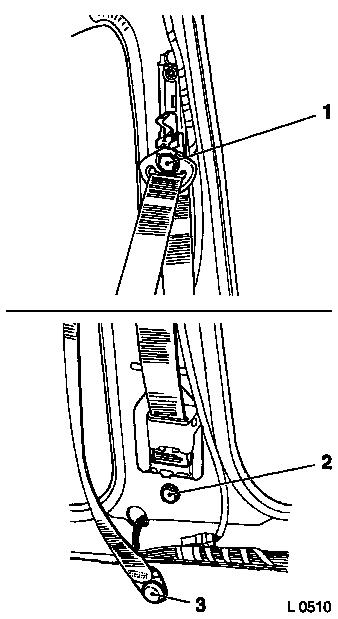

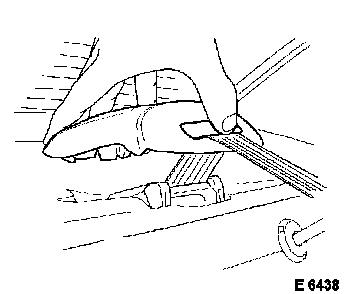

Application of Oscillating Cutter

All

screens approved for oscillating cutter (electric or pneumatic) (table page

7).

Note

instructions.

Before

starting, sharpen knife using commercially available whetting stone at low

speed.

Use

prescribed knife.

Observe

Service Instructions

Example,

Tigra tailgate screen (Knife Set MKM-846-50):

Area

1 Knife MKM-846-4

Area

2 Knife MKM-846-2

Area

3 Knife MKM-846-4

Area

4 Knife MKM-846-3

For

recutting, use Scraper Set MKM-846-70.

|

|

|

PU Activator

Only on new screens with PU

trim strips.

Sand

adhesive surface of PU trim strip with dry sandpaper grain P 80 - P 100.

Blow

off adhesive surface with compressed air.

Apply

PU activator on adhesive surface.

Allow

to dry for 10 minutes.

Apply

adhesive to activated surfaces.

Note: For Tigra tailgate

screen, do not apply PU activator to black screen print (A).

The

PU activator can cause residue to mix with the glass primer (possible

disruption of adhesion).

Use

only glass primer on screen print.

Important: Note

instructions enclosed with adhesive set.

Only

PU activator guarantees optimal adhesion of the screen adhesive.

|

|

|

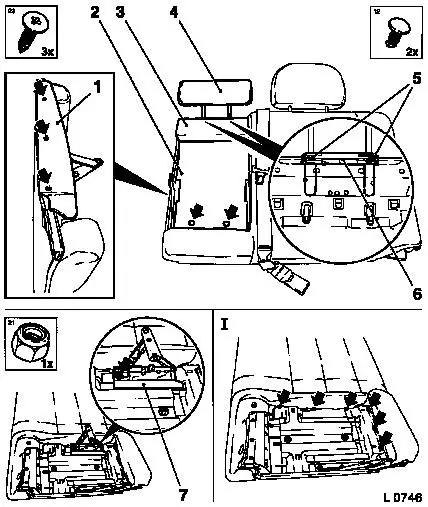

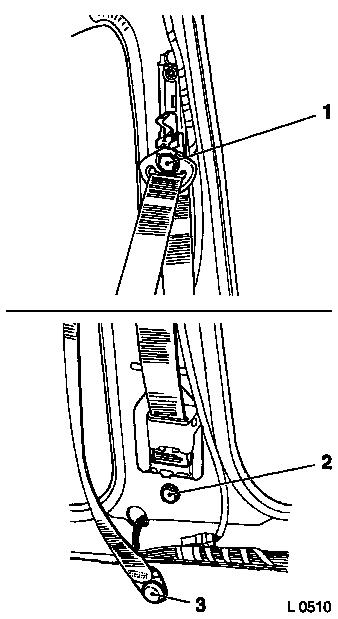

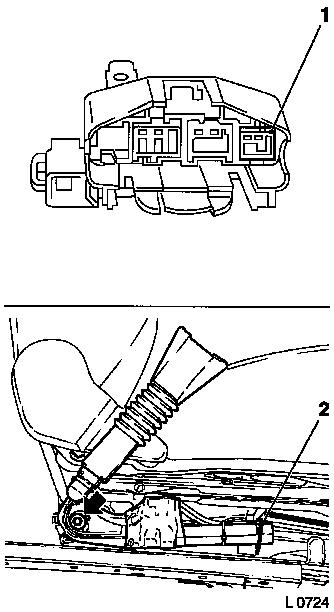

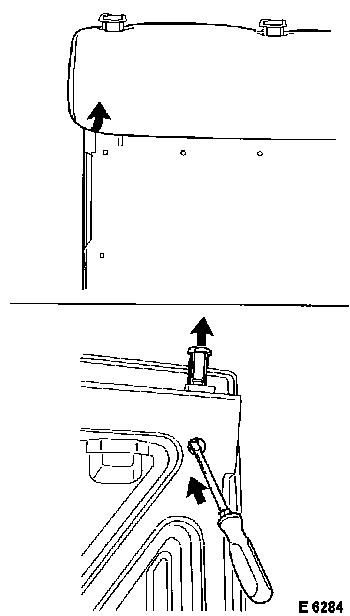

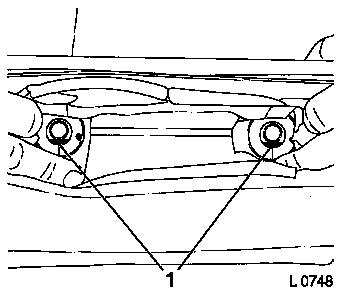

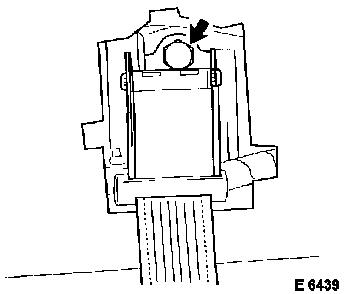

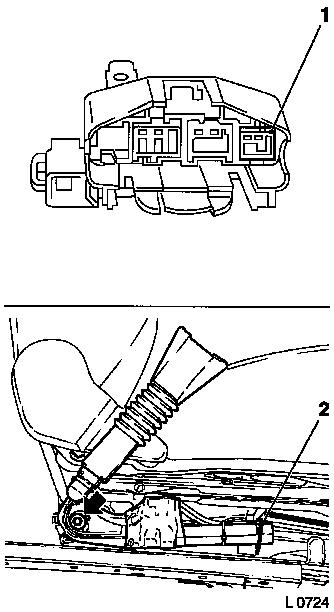

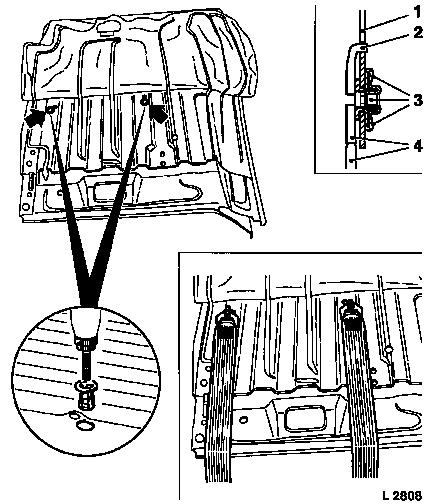

Adhesion

Place

screen on holder (1)

Alternatively,

use flat commercially available holding frame for working with Betagun

(easier application)

Prepare

screen.

Apply

adhesive using precut triangular nozzle from adhesive set (2).

Apply

adhesive only to screen

Bond Parts

Insert

screen (3).

Align

as specified in Service Instructions.

Apply

only light pressure (hand or tensioning belt).

To

prevent excessive tension and the risk of glass breakage, maintain a minimum

distance of 4 mm/0.16 in. (4).

|

|

|

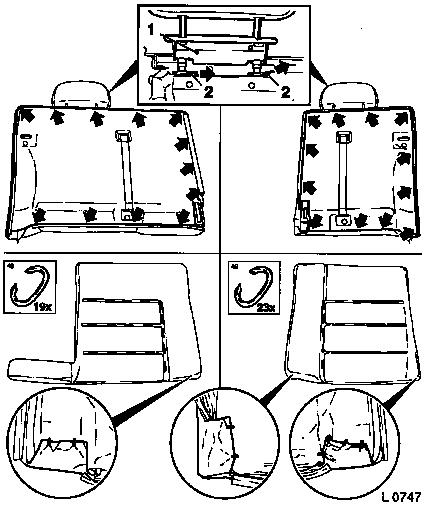

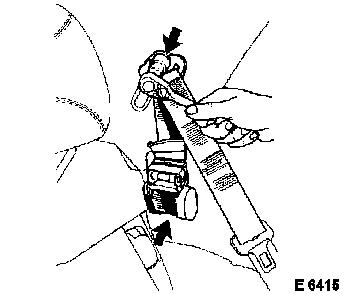

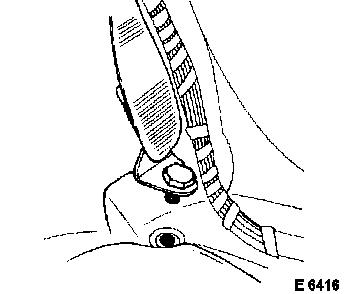

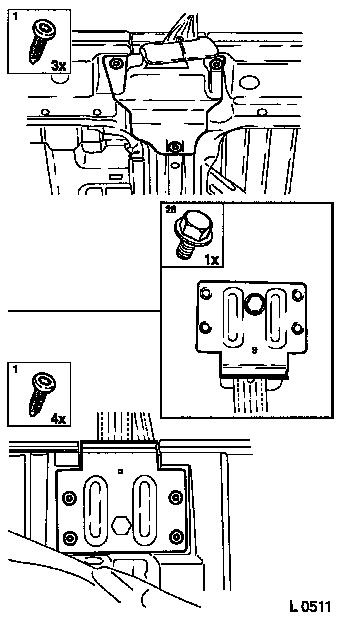

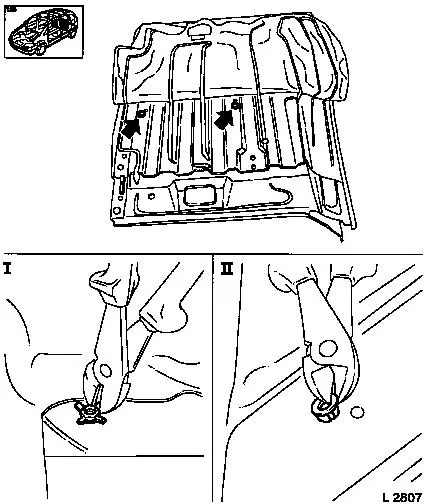

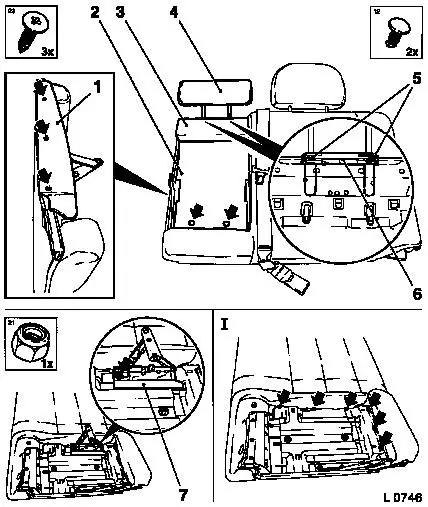

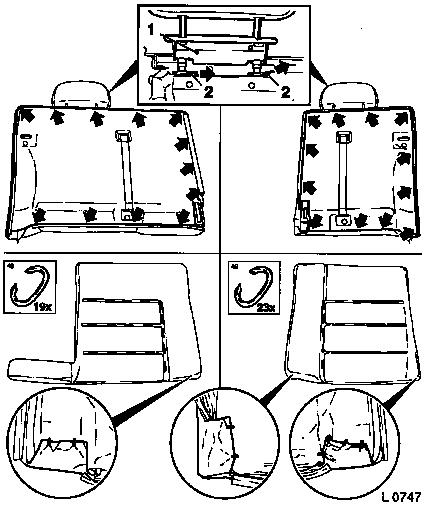

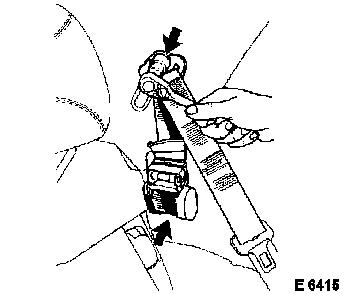

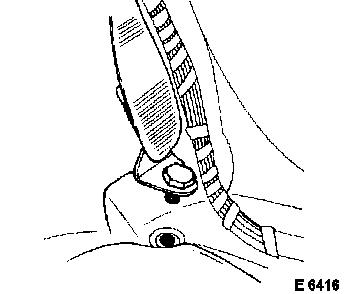

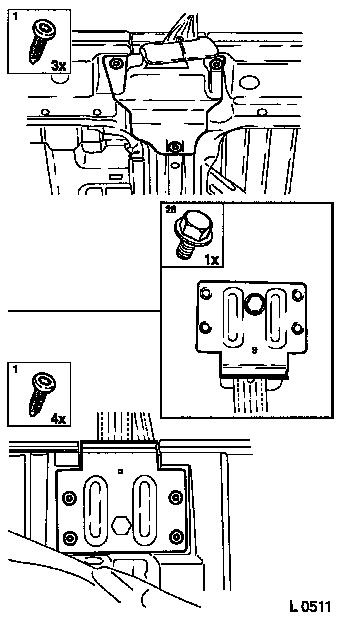

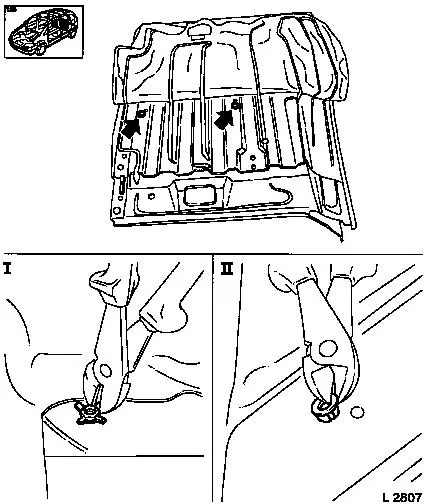

Tensioning Belts

All

screen types have intrinsic pretension. Therefore, tensioning belts must only

be applied with light pressure, even for vertical screens.

Important: Risk of glass breakage

(tension) after the adhesive has hardened if the screen frame is too close to

the body flange.

Minimum

distance from glass to body should be 4 mm/0.16 in.

Select

correct position of rubber pad:

1

= Correct

2

= Incorrect

Remove

tensioning belts after approx. 1 hour, to ensure that the remaining hardening

process is free of tension.

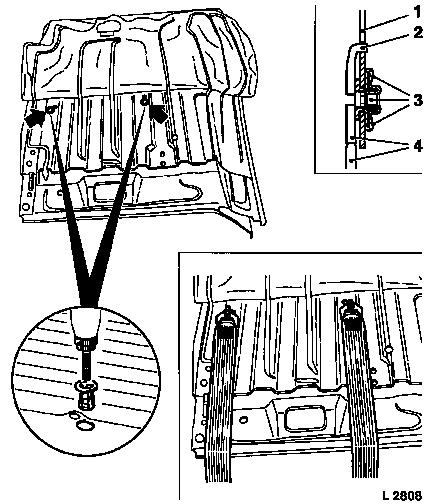

Important: Install

tailgate screen for Tigra with Screen Installation Set MKM-848:

MKM-848-1 Upper

Spacer

MKM-848-2 Fixing

Piece, Side

MKM-848-3 Rear

Spacer

Do

not use tensioning belts.

|

|

|

Waiting Periods

Vehicles

with and without driver's airbag:

If

1-component screen adhesive is used:

Put

vehicle into operation at the earliest after 2 hours.

The

adhesive is hardened after 36 hours.

Hardening

is caused by air humidity (physical curing).

If

2-component adhesive set is used:

Vehicle

is unconditionally ready for operation after 1 hour.

Hardening

is caused by a chemical reaction.

Vehicles with driver's and co-driver's airbags:

If 1-component or 2-component adhesives are used:

Allow vehicle to stand overnight.

|

|

|

|

|

Environmental

Protection/Disposal

1-component

adhesive: Normal refuse

2-component

adhesive set: Press out remains from cartridge. Dispose of in normal refuse.

Dispose

of black primer, cleaner and PU activator in special refuse.

Note: Observe instructions enclosed in adhesive set.

Parts

1-component

Screen Adhesive - 310 ml Part no. 90 166 373,

Cat. no. 15 04 802

Physical

curing with air humidity,

36

hours.

2-component

Screen Adhesive Set - 310 ml Part no. 90 443 098 Cat.

no. 15 04 807

Processing

with mixer rod Part no. 90

397 005 Cat. no. 15 04 805

Chemical

curing, 1 hour or overnight.

2-component

Screen Adhesive Set - 2 x 225 ml Part no. 90 398 386 Cat.

no. 15 04 806

Processing

with electric handgun

Betagun

2000 and forced mixing (Euroline).

Chemical

curing, 1 hour or overnight.

Locking

Compound Part no.

90 167 347 Cat. no. 15 10 177

For

adhesion of trim strip ends

Glue Part

no. 90 297 969 Cat. no. 15 00 005

For

adhesion of trim strip ends

Safety

Regulations

Note:

Perform

all work described in the operations in observance of valid national legislation,

accident prevention regulations, regulations from trade guilds or similar

organisations.

The

legislation regarding road traffic safety of motor vehicles applies.

Observe

the relevant legal requirements regarding environmental safety and health

protection.

Note

the instructions on the packaging and enclosed package slips.

Time

Allowance

The

time allowances can be found in the relevant valid Labour Time Guide catalogues.