|

Attaching Parts from Cylinder Head, Detach and

Reattach

Remove Remove

Remove cylinder head – see operation "Cylinder Head,

Remove and Install".

Caution

Lay cylinder head aside on wooden blocks to avoid damaging the

injection nozzles, glow plugs and valves.

|

Remove Remove

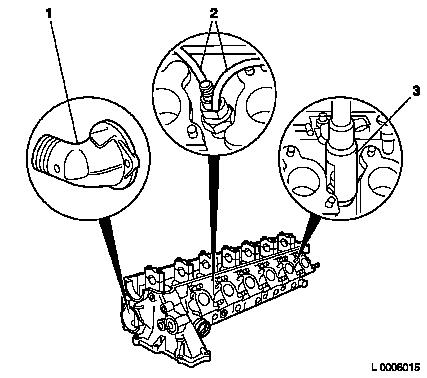

Detach thermostat housing (1) from cylinder head.

Detach oil leak lines (2) from injector nozzle holder.

Remove injection nozzle holder from cylinder head with KM-133-C

(3).

|

|

|

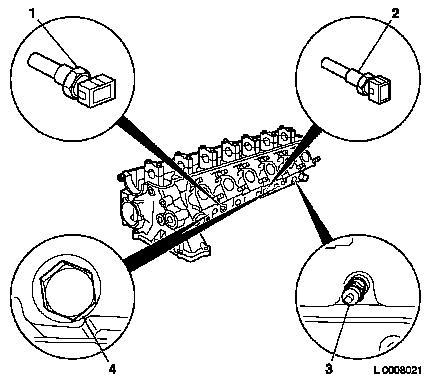

Remove sheathed glow plugs (3).

Remove temperature sensors (1) and (2) out of cylinder head.

Remove both closure plugs (4) out of cylinder head.

|

|

|

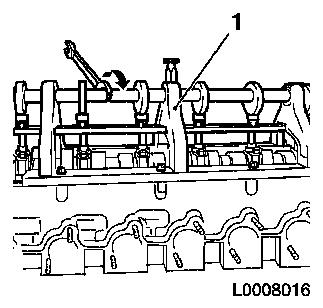

Attach Camshaft Hold Down Device KM-839 (1) to cylinder

head.

Pre-tension camshaft bearing cap by turning the eccentric shaft

of the Camshaft Hold Down Device KM-839 in direction of arrow.

Remove camshaft bearing caps evenly, working from outside to

inside.

Relieve tension in camshaft bearing cap by turning the eccentric

shaft of the Camshaft Hold Down Device KM-839 in direction of

arrow.

Remove Camshaft Hold-Down Device KM-839 from cylinder head.

Lay camshaft bearing caps aside according to cylinder

allocation.

Remove camshaft.

|

|

|

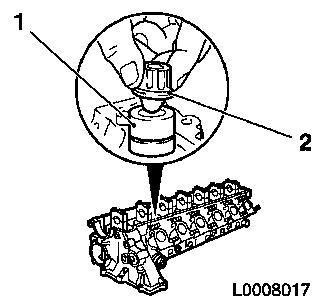

Pull out hydraulic valve lifter (1) with KM-845 (2) and lay

aside according to valve allocation – do not damage running

surfaces of hydraulic valve lifter.

|

|

Note: Check/overhaul

cylinder head – see operation "Cylinder Head and Attaching

Parts, Check and Align" and/or "Cylinder Head, Overhaul".

Install

Install

Insert camshaft such that the 1st cylinder cam points

upwards.

Attach camshaft bearing caps in cylinder order.

Attach Camshaft Hold Down Device KM-839 to cylinder head.

Carefully pre-tension camshaft bearing caps.

Tighten camshaft bearing caps each in steps of 1/4 turn from

inside outwards – tightening torque 15 Nm / 11 lbf. ft.

Remove Remove

Remove Camshaft Hold-Down Device KM-839 from cylinder head.

Install

Install

Install closure plug with new gasket in timing case –

tightening torque 9 Nm / 6 lbf. ft.

Screw both temperature sensors into cylinder head –

tightening torque 15 Nm / 11 lbf. ft.

Install sheathed glow plugs – tightening torque 22 Nm / 16

lbf. ft.

Attach injector nozzle holder with new seal ring to cylinder

head using KM-133-C – tightening torque 60 Nm / 44 lbf.

ft.

Connect leakage oil lines to injection nozzle holder.

|

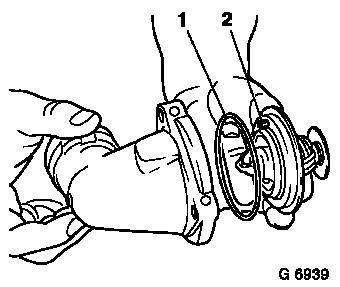

Insert seal (1) into thermostat housing. Insert thermostat into

thermostat housing.

Note: Insert

thermostat bleeding valve (2) into the guide.

|

|

Install

Install

Attach thermostat housing to cylinder head – 10 Nm / 7

lbf. ft.

|