|

Cylinder head, assemble

Special service tools required:

Assembly tool set KM-6215, installation/removal set MKM-6086,

KM-958, KM-835-A, KM-6152, KM-6385, KM-663, KM-352

|

Inspect

Inspect

Preconditions: All components are cleaned and checked. Cylinder

head is attached to assembly device and is upside down.

Assemble

Assemble

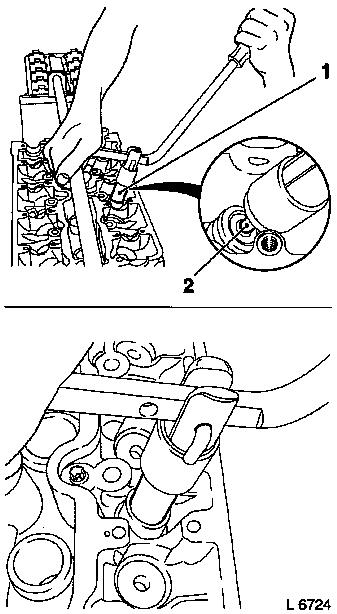

Lightly coat valve guides with oil and insert in cylinder head

in the appropriate sequence. Insert counterhold.

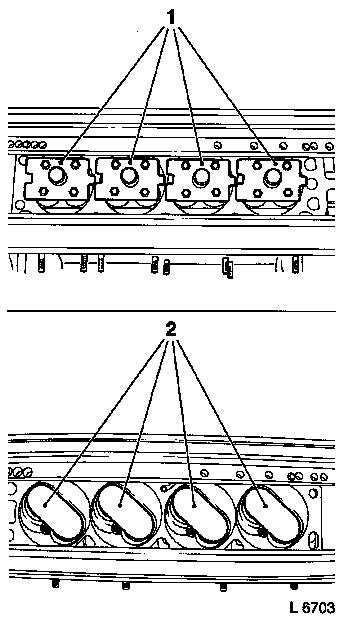

Depending on the combustion chamber design, different

counterholds (1 and 2) must be used to secure the valves.

The counterholds and fastening tools to be used can be found in

the survey .

|

|

|

Install

Install

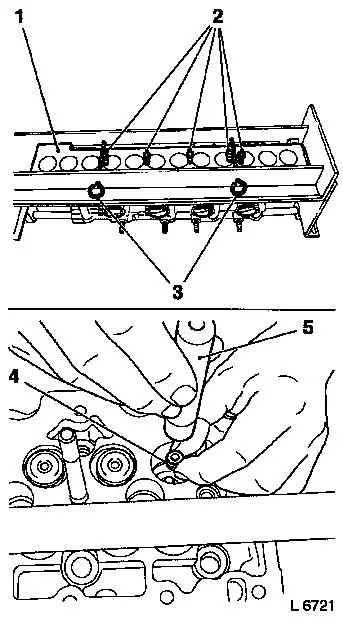

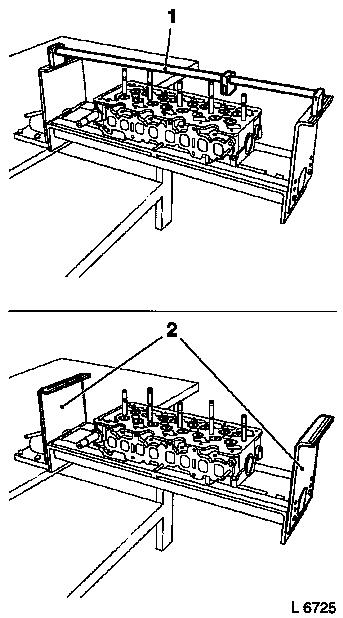

The counterhold KM-6215-2 (1) is only required for cylinder

heads with 2 valves per cylinder.

Fit counterhold KM-6215-2 (1). Attach with locking pins

KM-6215-3 (3). Turn fixing screws (2).

Turn assembly device over.

Insert lower valve spring cap / valve rotators in the

appropriate sequence.

Carefully install valve stem seals (4)

with the relevant installers (5).

|

Valve stem Ø

|

Installer

|

|

5 mm

|

KM-958

|

|

6 mm

|

KM-835-A

|

|

6 mm

|

KM-6152 (Z 22 SE)

|

|

6 mm

|

KM-6385 (Y 30 DT)

|

|

7 mm

|

KM-663

|

|

8 mm

|

KM-352

|

|

|

|

Insert valve springs and valve spring cap in cylinder head in

the appropriate sequence.

Caution

The components of the assembly head must be assembled according

to the following instructions.

Assemble

Assemble

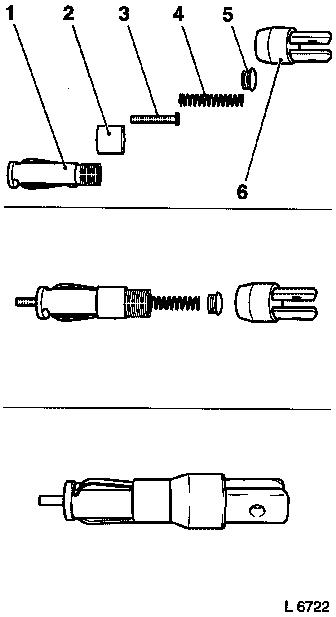

The assembly head consists of: mount (1), retaining sleeve (2),

thrust piece (3), spring (4), screw connection (5) and lever

mounting (6). The assembly head must be assembled in the above

sequence.

Different thrust pieces are used depending on engine type. The

thrust pieces to be used can be found in the survey

The relevant sizes are stamped on the head of the thrust

pieces.

|

|

|

Caution

The combinations of support and thrust piece must always be

observed, as otherwise the valve cotters cannot be installed or the

thrust pieces are damaged.

The support and thrust piece combinations can be found in the

survey .

Assemble

Assemble

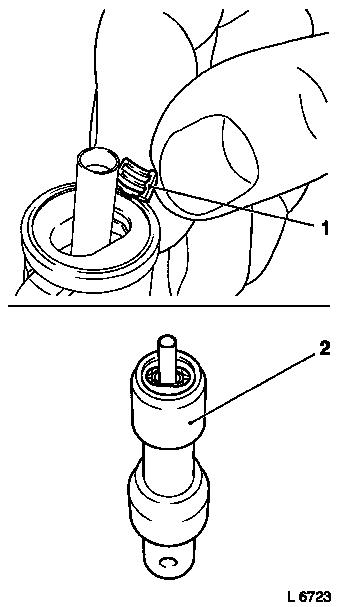

Slide retaining sleeve (2) downwards and insert valve cotters

(1) in the assembly head. Slide retaining sleeve (2) upwards, the

valve cotters are held in position.

Attach assembly head to lever MKM-6086.

|

|

|

Adjust (align) lever so that the assembly head is positioned

vertically above the valve.

Caution

To facilitate installation of the valve cotters, the assembly

head (1) should be attached to the valve stem with the thrust piece

(2). This prevents damage occurring to the thrust pieces.

Install

Install

Press down assembly head with lever slowly and carefully until

the valve cotters engage audibly in the valve stem. Then check

seating of valve cotters.

|

|

|

Remove Remove

Remove lever (1) and side mounts. Remove counterhold (2) and

wooden board.

Detach cylinder head from assembly device.

Clean Clean

After assembly of all attaching parts the cylinder head must be

cleaned thoroughly.

Install

Install

Install attaching parts and camshaft(s) to cylinder head.

|

|

|