Body Repairs using Adhesives and Welding "Adhesion" is understood to be the joining of identical or different materials by means of an inorganic or organic compound at room temperature or with moderate heating. The practical application of the adhesion method is limited to the self-supporting parts of the body (outer panelling of doors, outer rear quarter panels). This application must not be used for load-bearing parts, e.g. frames, members. The costs of repair and maintenance of a vehicle have a great influence on its appeal to the customer and therefore contribute to its competitiveness. Therefore, it is obvious that cost development must be constantly supervised, and that work methods that reduce costs be developed. The adhesive techniques developed by Opel/Vauxhall to suit the requirements of body repairs are a logical consequence of the principle of taking modern technologies that have proved themselves to be useful and economical in other commercial fields, e.g. in the aerospace industry. and then making them practicable for the automobile industry.

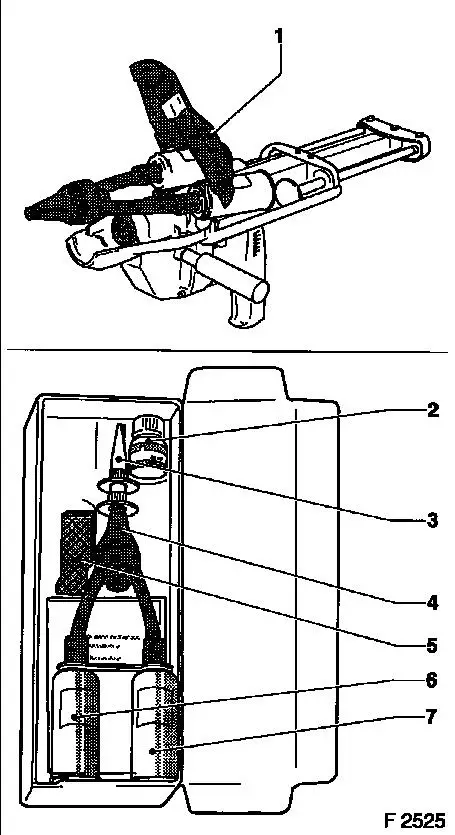

Body Repairs using Adhesives and Welding (Continued) The corrosion protection adhesive sealing system is available from the Aftersales department as a set. The new product replaces the familiar 2-component adhesive used for replacement of exterior panelling (doors). The adhesive is applied using the familiar BETAGUN 2000 (1). This ensures 100% mixing of the two adhesive components. Contents of adhesive set

|

2 |

Activator |

|

|

|

|

3 |

Two nozzles |

|

|

|

|

4 |

Mixing head |

|

|

|

|

5 |

Cleaning cloth |

|

|

|

|

6 |

Cartridge, adhesive component A - 125 ml |

|

|

|

|

7 |

Cartridge, adhesive component B - 125 ml |

|

|

Body Repairs using Adhesives and Welding (Continued) Description of operations and applications:

|

• Observe occupational health and safety regulations (see Part and Product Specifications) |

|

• Detach attaching parts and rear quarter panel |

|

• Remove residual adhesive from inside of rear quarter panel and grind adhesive area down to bare metal |

Notice: Adhesive in the area of separation points / edge welds must be protected from combustion by applying heat barrier paste to the adjoining sheet metal parts. |

|

Body Repairs using Adhesives and Welding (Continued)

|

Note: |

|

• Never apply weld paint on bright-finished adhesive flanges. |

|

• Grind adhesive area of new part to bare metal only in vicinity of spot welds (also applies to galvanised alloy parts). |

|

• Fit new part, observe cutting points |

|

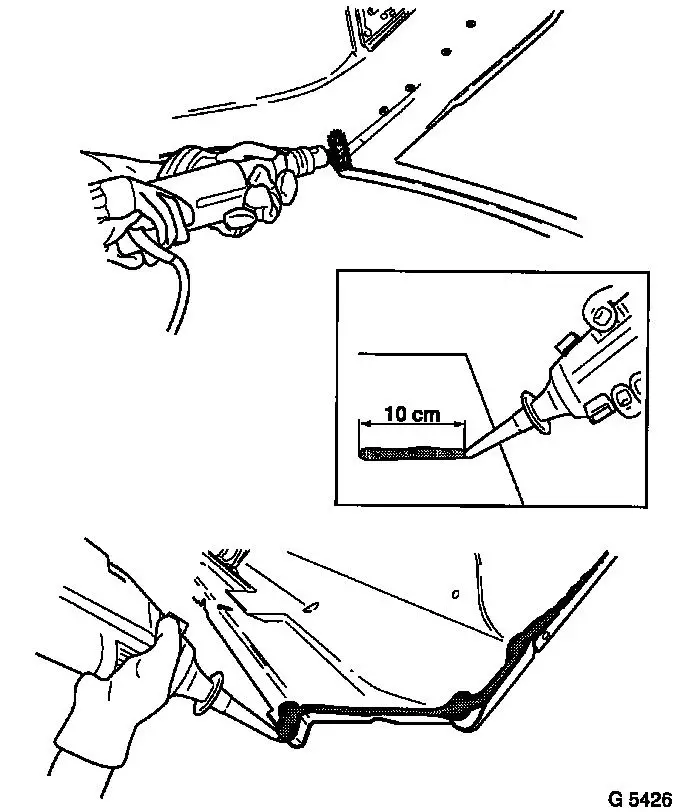

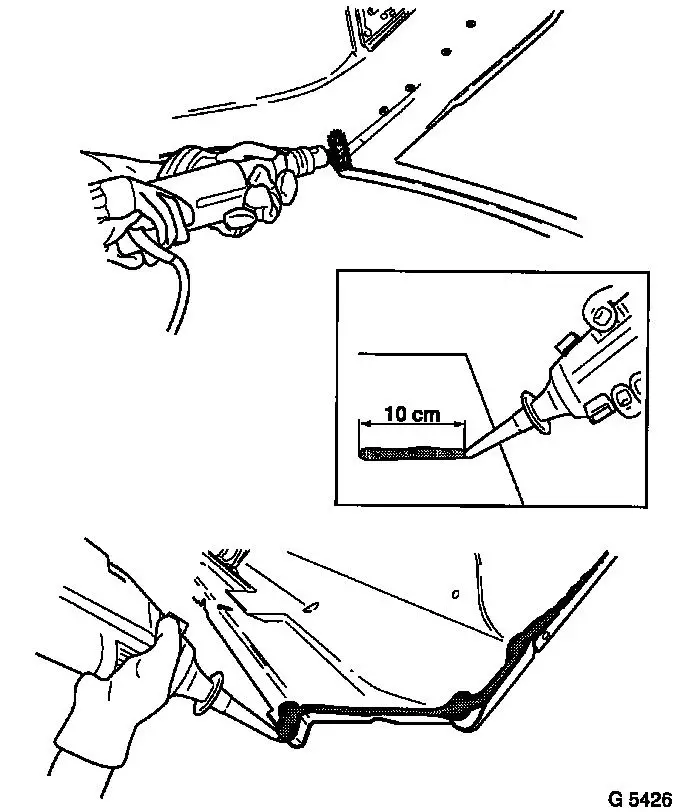

• Activate adhesive surfaces (new primed part) with activator from adhesive kit. Insert adhesive cartridges from adhesive kit in BETAGUN 2000; apply 10 cm/0.39 in. test bead (e.g. on cardboard). |

|

• Pre-cut cartridge nozzle (round nozzle) for 4 mm/0.16 in diameter. |

|

• Quickly apply adhesive bead, install new part. |

|

|

Part and Product Specifications

|

Parts |

Colour |

Container |

Part Number |

Catalogue Number |

Shelf Life |

|

Adhesive (complete adhesive set) |

beige |

2 cartridges on mixing head |

90 513 298 |

15 05 002 |

1 year |

|

Product Specifications |

• Spot-weldable flange seam adhesive for adhesion of outer and inner body panel parts. |

|

|

|

|

Treatment |

• Forced mixture of both components via mixing head and BETAGUN application |

|

|

|

|

Basic raw materials |

• Epoxy resin |

|

|

|

|

Application surfaces |

• Grind rear quarter panel down to bare metal only in vicinity of spot welds, cement adheres to activated new part primer. |

|

|

|

|

Pre-treatment |

• Clean surface (activate) with activator before applying adhesive. |

Part and Product Specifications (Continued)

|

Application |

• Perform all operation steps quickly and without interruption. Adhesive bead approx. 4 mm diameter. |

|

|

|

|

|

|

• Process cement at ambient temperature between 15 ° C and 30 ° C; sheet metal temperature between 18 ° C and 40 ° C. |

|

|

|

|

|

Paintability |

• Paint using OPEL paint repair systems |

|

|

|

|

|

Disposal |

• The following provides general information regarding disposal (national legislation that may deviate from this must be observed): |

|

|

|

|

|

|

• Ordinary refuse |

Adhesive residue squeezed from nozzle, plastic nozzles with adhesive, cleaning cloths with adhesive residue, packaging |

|

|

|

|

|

|

• Special refuse |

Mixing head with lifting tubes (curing time 4 hours), adhesive cartridges not fully emptied, activator fluid residue (usually completely applied) |

|

|

|

|

|

|

• Aluminium waste |

Emptied adhesive cartridges, activator container |

|

|

|

|

|

|

• Plastic waste |

Activator container cover, activator lift top |

Part and Product Specifications (Continued)

|

Work safety |

• The following provides general information regarding work safety (national legislation that may deviate from this must be observed). |

|

|

|

|

|

|

• Eye protection |

Wear protective goggles during operations involving chemical products. If chemicals come in contact with eyes, immediately wash eyes with clean water, seek medical attention. |

|

|

|

|

|

|

• Lung protection |

Adhesion and welding operations must be performed in well-ventilated areas, wear type AB filter masks for short-term welding operations. For long-term welding operations, additionally ensure that vapours are effectively suctioned away. |

|

|

|

|

|

|

• Skin protection |

Wear protective gear, safety gloves. Use silicone-free protective lotions or salves. If adhesive comes in contact with skin, wash skin with soap and water, do not use solvents of any kind. |

Body Repairs using Adhesives and Welding (Continued) Today, adhesive connection can be regarded as extremely reliable. The prerequisite for a stable connection standing up to the stresses occurring in the adhesion area is, in addition to strict observance of the processing instructions contained in the service literature and in the packaging of the adhesive containers, the correct preparation and shaping of the joining surfaces and joining parts. The firmness of the adhesive connection depends on the internal binding forces of the adhesive and on the binding forces of the adhesive layer and the joining part surfaces. Besides the specific properties of the adhesive, the characteristics of the joining surface in the adhesive area are therefore also particularly important. The thorough cleaning of the joining parts in the area of the joining surface is the prerequisite for secure adhesion. Any grease and wax remnants, oxide layers, rust, scales, paint r and primer must be completely removed from the adhesive surfaces. Use only the solvent from the corrosion protection adhesive/sealing system corrosion protection. Never use alcohol, benzene or paint thinner.

Body Repairs using Adhesives and Welding (Continued) Further development of adhesive now allows spot and edge welding to be performed even on a wet adhesive bed. The "sealing adhesive system for anti-corrosion protection Part No. 90 513 298 / Catalogue No. 15 05 002" intended for adhering, is designed for the special requirements of body repairs and must only be used in the prescribed forced mixture using the Betagun pistol. It must never be replaced by or mixed with other unauthorised materials. When using two component adhesive based on epoxy resin, precisely observe the processing instructions and safety measures of the manufacturer and relevant institutional regulations. When processing adhesive materials, special safety measures must be observed in order to avoid damage to health. The same restrictions apply here as for paint materials. Avoid direct skin contact with adhesives. Unhardened epoxy resin adhesive can irritate sensitive skin. If adhesive comes into contact with skin, wash immediately with warm water and soap. Then rub in skin protection cream. If adhesive spray gets into the eyes, wash out immediately with plenty of luke-warm water for 10 to 15 minutes. Contact an eye specialist.

|