|

Adjusting the timing: Option 1

Lock pin of injection pump does not fit in

retaining bore of injection pump flange

Note: Crankshaft is

locked at "1st cylinder TDC" with Lock Pin KM-929.

Remove Remove

|

|

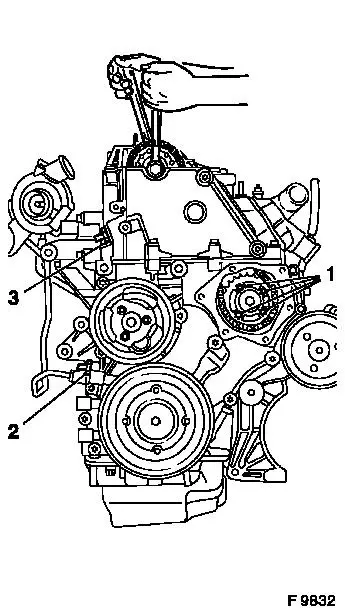

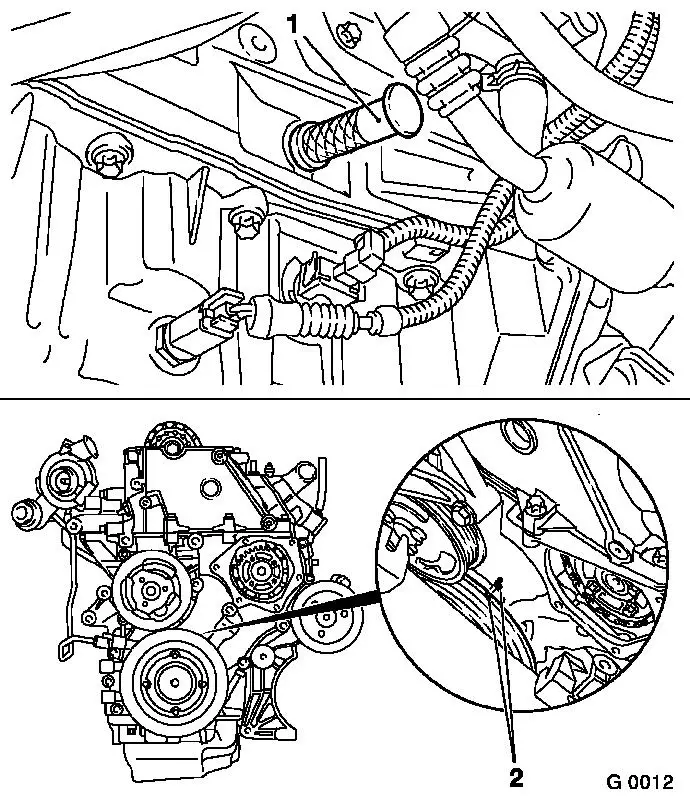

Detach engine damping block adapter from timing case. Remove

simplex chain tensioner (3) and duplex chain tensioner (2) - note

installation position. Detach fastening bolt for camshaft sprocket

from camshaft - counterhold with open-ended wrench at camshaft

hex.

Install

Install

Insert new fastening bolt for camshaft sprocket and hand-tighten

- ensure that the camshaft sprocket is seated squarely on the

camshaft. The camshaft sprocket must be seated flush on the

camshaft.

Remove Remove

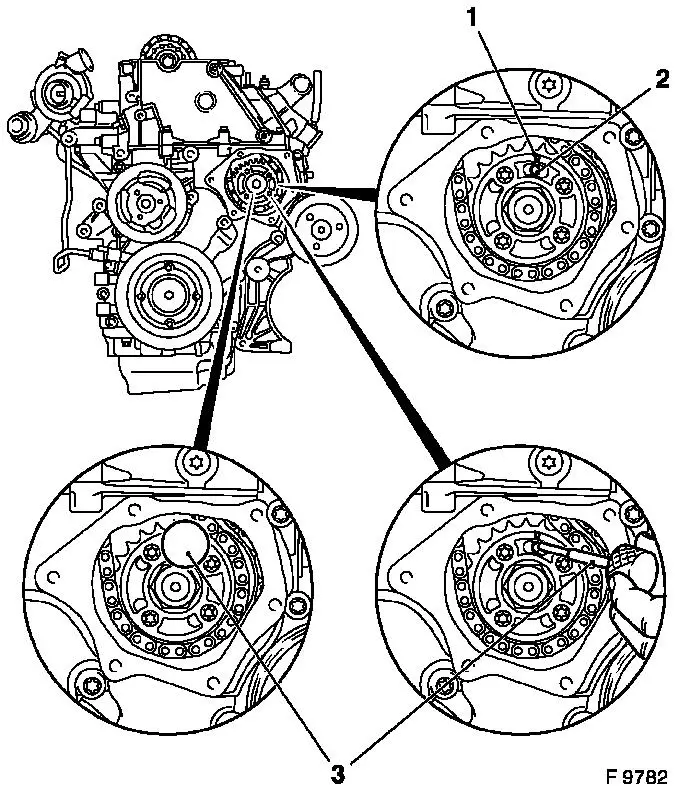

Release fastening bolts (1) for Simplex injection pump gear -

ensure bolting strength equals 10.9, replace fastening bolt if

required.

Caution

The factory-fitted fastening bolts of the Simplex injection pump

gear must be replaced after slackening for the first time.

The factory-fitted fastening bolts of the Simplex injection pump

gear do not have to be replaced after slackening for the first

time.

|

|

Adjust Adjust

|

|

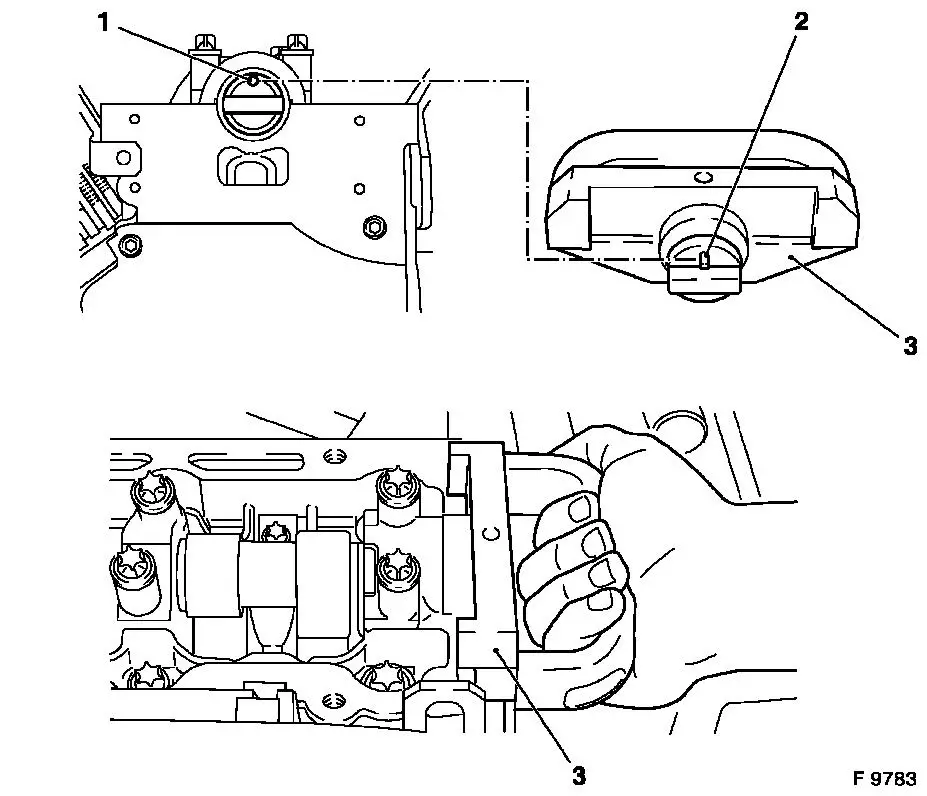

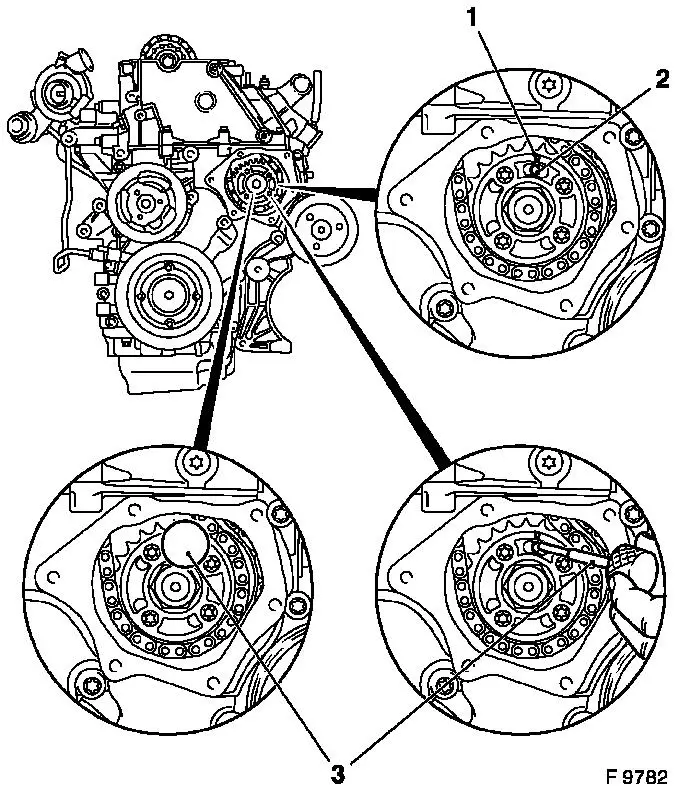

Turn injection pump gear until the arrow (1) on the Simplex

injection pump gear is aligned with the recess in injection pump

flange and retaining bore (2) in injection pump.

|

|

Install

Install

Insert Injection Pump Lock Pin KM-927 (3) to stop in lock bore

fuel injection pump.

Install

Install

|

|

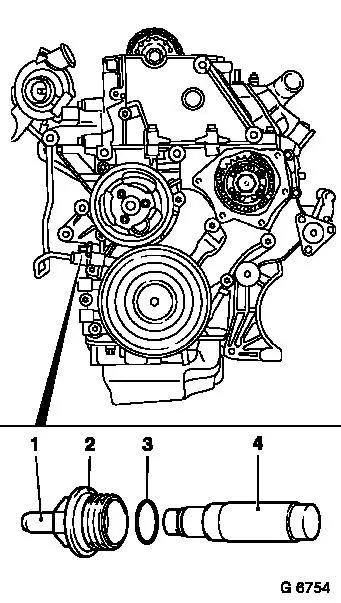

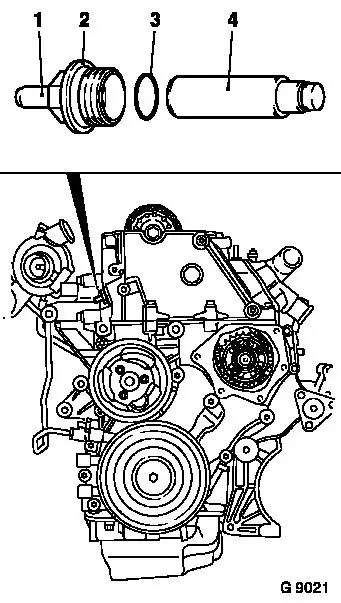

Insert Duplex chain tensioner (4) in timing case - closed side

of chain tensioner must face towards tension rail. Install closure

bolt (2) with new seal ring (3) - tightening torque 60 Nm / 44 lbf.

ft.

Caution

When installing new Duplex chain tensioner, chain tensioner must

be released by means of release bolt (1) after assembly. Push in

release bolt with hammer handle until click is audible.

It must be possible to push in release bolt up to stop with

thumb and for it to slide back to its original position

automatically - the release bolt can no longer be pushed in once

the oil pressure has built up.

|

|

Remove Remove

|

|

Remove Injection Pump Lock Pin KM-927.

|

|

Install

Install

Tighten fastening bolts (1) with bolting strength 10.9 for

simplex fuel injection pump gear - tightening torque 28 Nm / 21

lbf. ft.

Insert Injection Pump Lock Pin KM-927 into fuel injection pump

lock bore again.

Install

Install

|

|

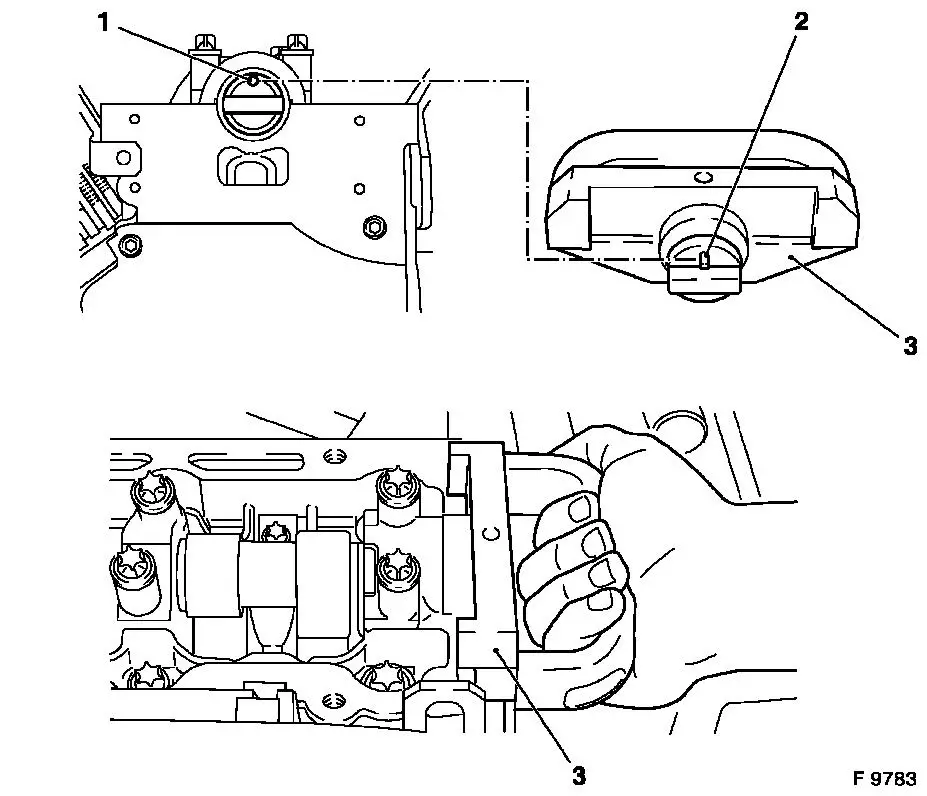

Place Test Gauge KM-932 (3) on cylinder head - pin (2) must

engage in camshaft bore (1) - if necessary turn camshaft slowly and

smoothly at hex (short route).

|

|

Install

Install

|

|

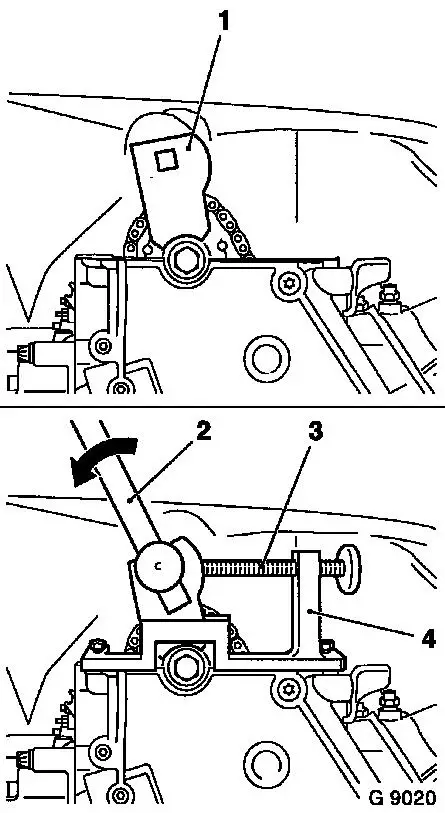

Insert carrier (1) of Adjuster KM-933 (4) vertically in camshaft

sprocket. Mount Adjuster KM-933 to cylinder head with accompanying

bolts.

|

|

Adjust Adjust

Use handle (2) to exert slight pressure on the carrier in the

direction of arrow (counter engine rotational direction) and fix in

place with holder bolt (3).

Removal and installation of Retaining Pin KM-927 for fuel

injection pump must be possible under suction. If this is not

possible, the pressure on the adapter plate must be slightly

reduced using the adjustment screw (3).

Install

Install

Fasten camshaft sprocket to camshaft - tightening torque 90 Nm /

66 lbf. ft. + 60° + 30°.

Install

Install

|

|

Insert simplex chain tensioner (4) in cylinder head - closed

side of chain tensioner must face tension rail. Install closure

bolt (2) with new seal ring (3) - tightening torque 60 Nm / 44 lbf.

ft.

Caution

When a new simplex chain tensioner is installed, following

installation, the chain tensioner must be released via the release

pin (1).

Inspect

Inspect

Press in the release pin with a hammer shaft until a click is

heard.

It must be possible to push in release bolt up to stop with

thumb and for it to slide back to its original position

automatically - the release bolt can no longer be pushed in once

the oil pressure has built up.

|

|

Remove Remove

|

|

Remove all locking and adjusting tools.

|

|

Adjust Adjust

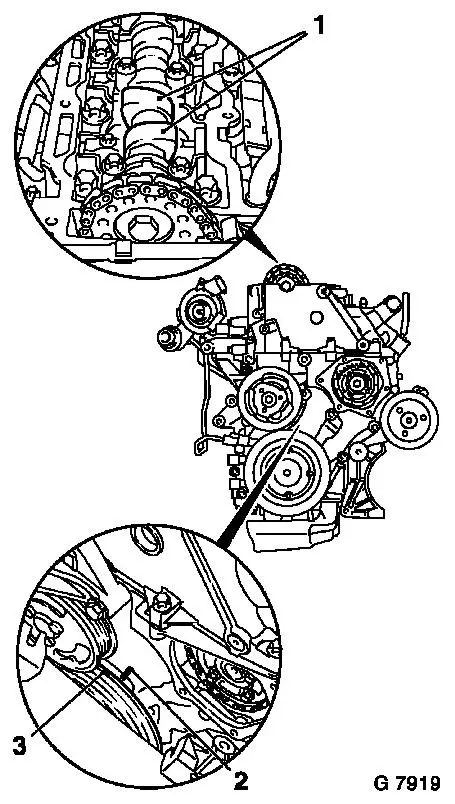

At the torsional vibration damper fastening bolt, turn

crankshaft slowly and smoothly for two rotations (approx. 720°)

in direction of engine rotation until just in front of 1st cylinder

ign. TDC - mark (3) on torsional vibration damper is located just

in front of timing case lug (2).

Inspect

Inspect

In this position, the cams (1) of the 1st cylinder are just

before TDC (both cams point upwards).

Install

Install

|

|

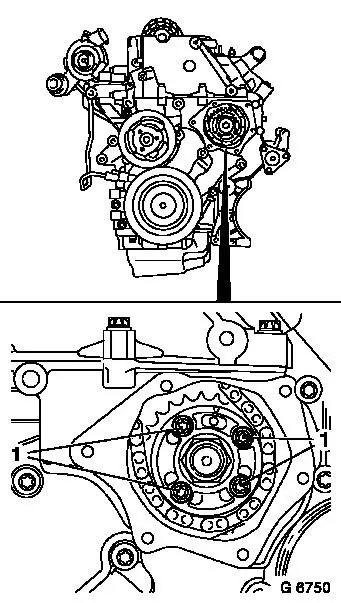

Insert Crankshaft Lock Pin KM-929 (1) in crankshaft pulse

pick-up aperture and simultaneously continue turning crankshaft

slowly and smoothly in direction of engine rotation using fastening

bolt for torsional vibration damper so that crankshaft retaining

pin engages to the stop in cylinder block or crank web.

|

|

Inspect

Inspect

In this position, the marks (2) must be aligned.

Inspect

Inspect

|

|

Arrow (1) on Simplex injection pump gear must be aligned with

the recess in injection pump flange and retaining bore (2) in

injection pump.

|

|

Install

Install

Insert Injection Pump Lock Pin KM-927 (3) in lock bore of fuel

injection pump.

Install

Install

|

|

Place Test Gauge KM-932 (3) on cylinder head - pin (2) must

engage in the camshaft bore (1).

|

|

Remove Remove

Remove all locking tools.

Install

Install

Install removed components - see operation "Engine, Lock at 1st

Cylinder TDC (Timing, Check)".

|