Field Remedy: 2379

| Subject: |

Two-mass flywheel - Diagnosis |

| Models: |

Engines: |

Option: |

| All |

All |

|

| Complaint: |

|

| Cause: |

|

| Production: |

|

Remedy:

These Quick Information shall help to carry out a

correct diagnosis in case of a customer complaint.

A. Check for thermal overload:

Through friction of clutch plate on the friction surface of

the two-mass flywheel temperatures up to 200 °C can arise

during normal driving. At sliding clutch or through operating

errors much higher temperatures can arise. These temperatures

must not cause mandatory a reduced lifetime of the two-mass

flywheel.

Possible indications for a high thermal load are:

- tarnish (bluish) as well as local hotspots on friction surface

- tarnish (bluish) near of mounting area and riveting area of

clutch

If all other checkable features are well, the two-mass flywheel

can stay in the vehicle.

Possible indications for a too high thermal load are:

- cracks

- fusion zones on friction surface (material smear)

- scores in friction surface (for example through clutch lining

riveting at destroyed or worn clutch plate)

- tarnish (bluish) which reaches up to bearing area of two-mass

flywheel

- bluish discoloration of locating pins (3 locating pins in outer

zone of two-mass flywheel)

In these cases the two-mass flywheel has to be replaced.

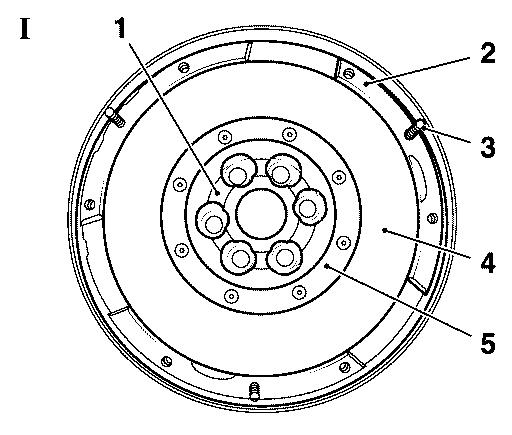

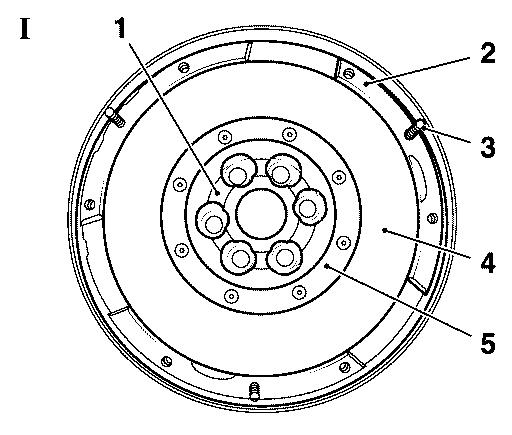

Overview two-mass flywheel (picture I):

1 bearing area

2 mounting area pressure plate

3 locating pins

4 friction surface

5 riveting area

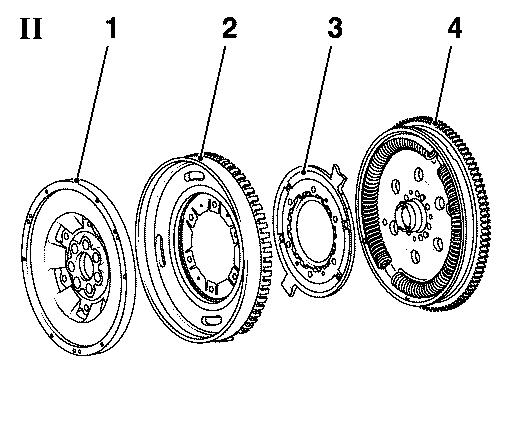

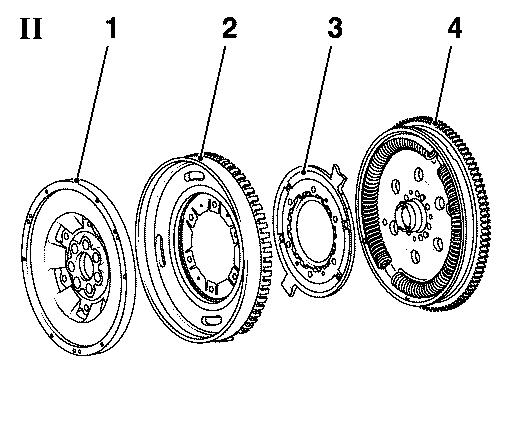

Exploded view two-mass flywheel with additional mass (picture II):

1 secondary flywheel mass

2 additional mass, coupled with cover and pulse-generator ring

3 flange

4 primary flywheel mass with bowed springs and plain bearing/

bearing bolt

5 toothed ring

B. Check for damaged components:

All following checking procedures have to be carried out

at installed two-mass flywheel. For visual check at vehicle

very bright light and a additional bright and small pocket

lamp is necessary. Damages like grease on primary flywheel

and loose ore missing balance weights cannot be checked at

installed condition. During visual check material alteration

can be stated which eliminate a further operating suitability.

For comparison different damages at two-mass flywheel with the

corresponding further procedure are presented here.

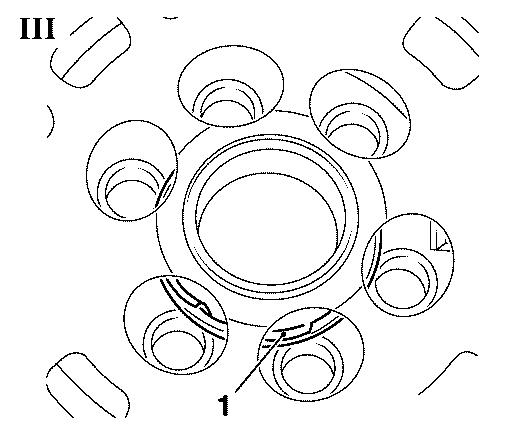

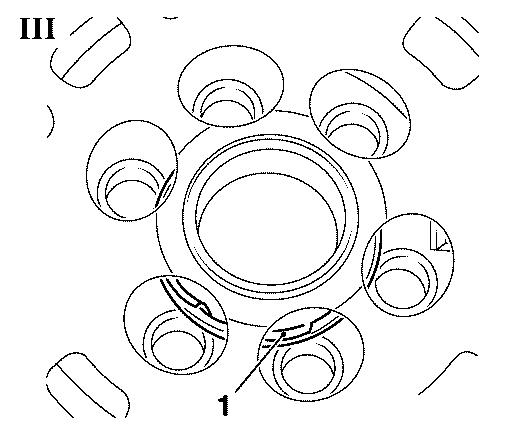

1. Inspect plain bearing for damages (picture III)

Dependent of the manufacturer damages can be detected through

ventilation openings of secondary flywheel. Parts of the bearing

(1) are detached or lie loose around the bearing bolt.

Note:

In case of mechanical damages at plain bearing the two-mass

flywheel has to be replaced.

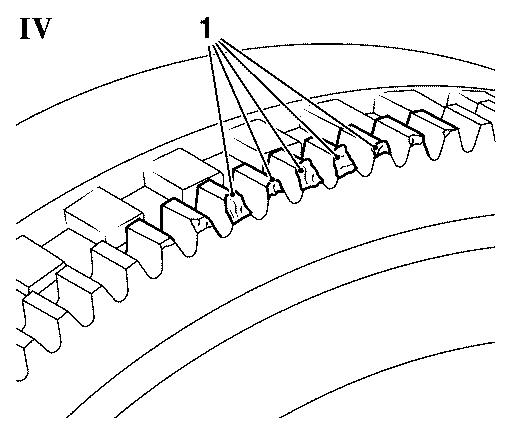

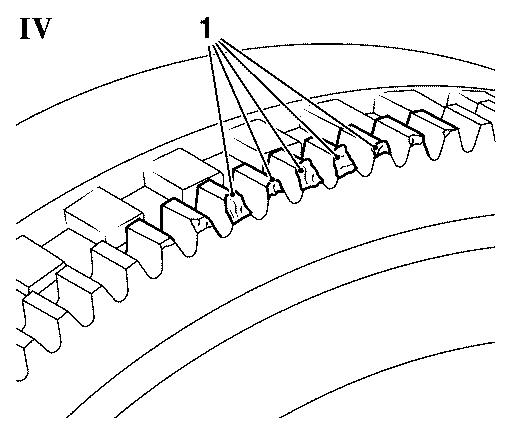

2. Inspect toothed ring for damages (picture IV)

The toothed ring is needed to start the engine. Through

a lot of starting procedures and/or an incorrect engaging

starter signs of abrasion can occur on teeth of the

toothed ring. The profile of damages can reach from only

low signs of abrasion up to heavy material removal. The

installation of a pulse-generator ring depends on the

manufacturer.

Image IV shows signs of abrasion and mechanical damages at

toothed ring (1), they occur through abrasion due to a lot

of starting procedures. In this case the two-mass flywheel

has to be replaced.

Note:

Light abrasion on frontal areas of teeth is allowed. If

problems occur during starting the engine the two-mass

flywheel has to be replaced.

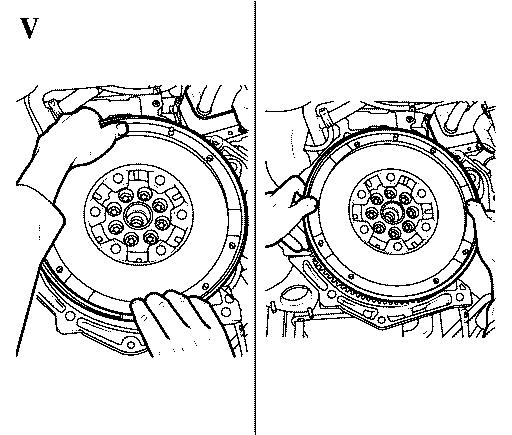

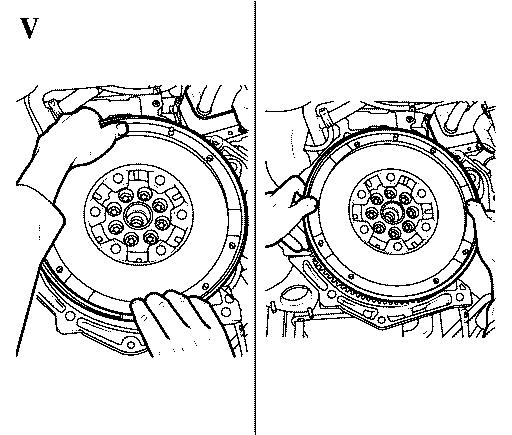

3. Inspect tilt clearance

At two-mass flywheel the additional-mass ring looms over

the gap between primary and secondary flywheel. It is not

possible to carry out just a visual check.

- Embrace two-mass flywheel and apply thumbs onto the outer

radius of secondary flywheel

- Apply pressure onto the secondary flywheel alternating on

upper, lower, left and right side (picture V).

During the tilt clearance check a functional metal rattling

noise may occur.

Note:

The check must be carried out only by hand without

any tools.

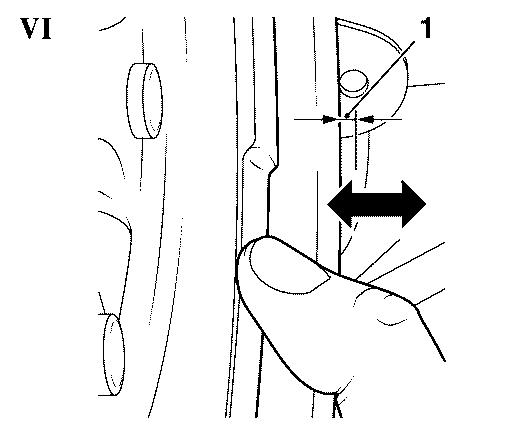

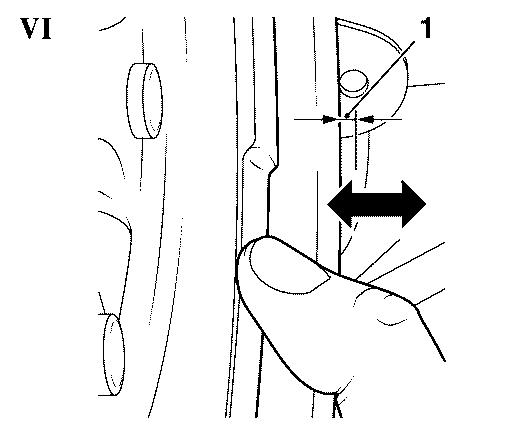

If tilt clearance is higher than 3 mm (should be measured, do

not make an estimation) (1, picture VI) the two-mass flywheel

has to be replaced.

Note:

An absolute clear measurement is not possible with this check

due to the different applied forces of the several workshop

employees during the check.

4. Inspect clearance angle

Before the inspection of the clearance angle the two-mass

flywheel should be rotated several times clockwise and

anticlockwise to receive a feeling for the resistance of

the springs. In addition unusual loud clicking noise or

possible rattle, crunch, grinding noise can be sounded out

during rotating the two-mass flywheel.

If the rotation of the flywheel is impossilbe the flywheel

is defective and has to be replaced.

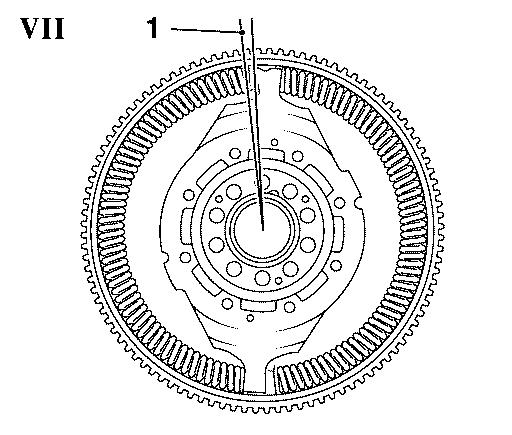

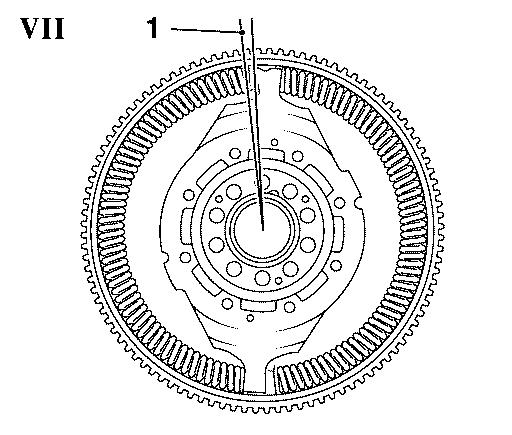

The clearance angle is the angle (1, picture VII) about the

secondary and the primary flywheel can be turned light against

each other. Thereby the flange wings (3) are moved in the duct of

the bowed springs without adjoining the bowed springs (4). Dictated

by functional factors the clearance angle is up to 8 teeth.

Is the secondary flywheel rotated beyond this point the bowed

springs in the duct are moved to spring arrestor (2) in the primary

flywheel/cover. First now the spring force of the bowed springs

is active.

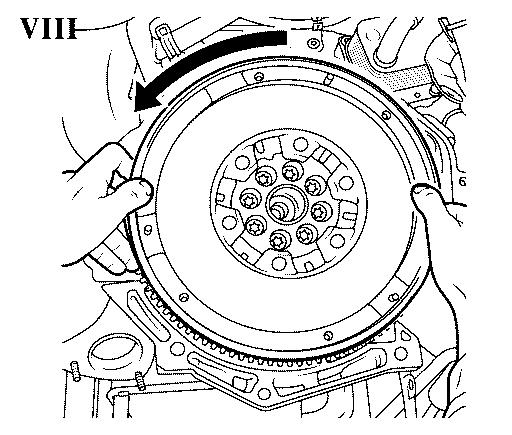

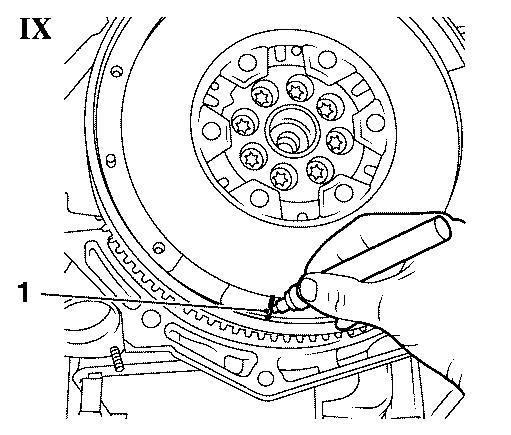

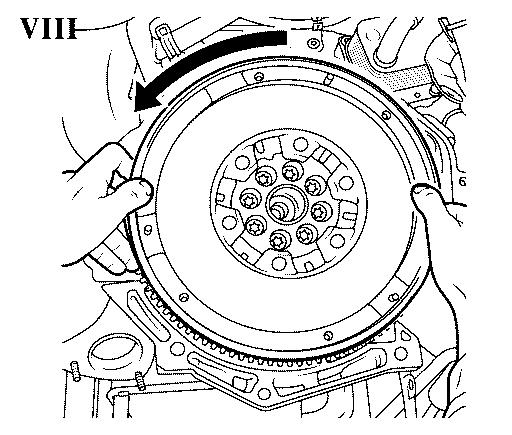

- Rotate secondary flywheel anticlockwise (arrow, picture VIII)

until the elastic counterforce (spring force) is clear noticeable

- Release secondary flywheel slowly until the bowed springs are

relaxed, so no counterforce acts onto the springs

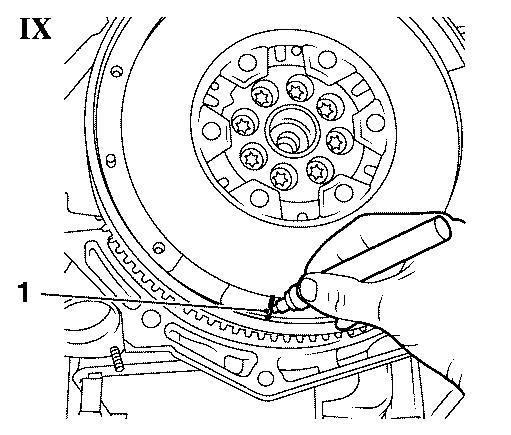

- Mark position with a vertical line by a white pencil

on secondary flywheel (1, picture IX and X) and on

toothed ring for starter (2, picture X)

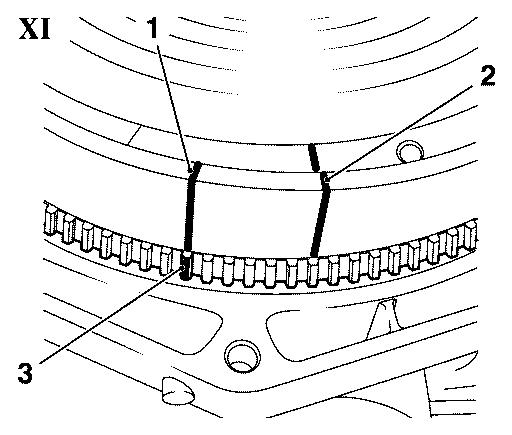

- Rotate secondary flywheel clockwise until the elastic

counterforce is clear noticeable

- Release secondary flywheel slowly until the bowed

springs are relaxed

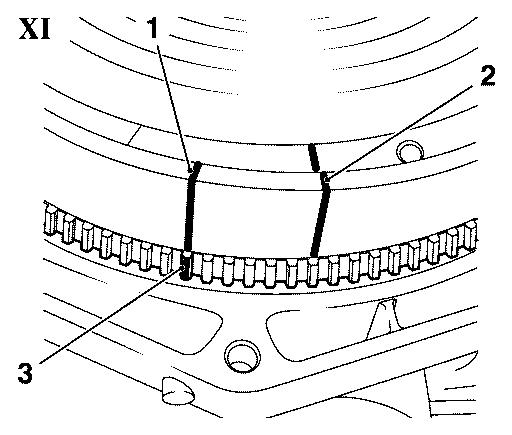

- Apply new marking on secondary flywheel (1, picture XI)

on the heigth of the marking on the toothed ring for

starter (3)

- Count amount of teeth on toothed ring for starter from

marked tooth up to the heigth of the first marking on

secondary flywheel(2). Dictated by functional factors

up to 8 teeth are allowed.

Note:

The two-mass flywheel has to be replaced if

- the difference exceeds the amount of 8 teeth

- the two-mass flywheel cannot be rotated

- during rotating the two-mass flywheel a hard metallic

arrestor is audible or noticeable.

| FunctionalGroup: |

J - Engine |

| Complaint Group: |

13 - No/Poor Function |

| Trouble Code: |

None |

|