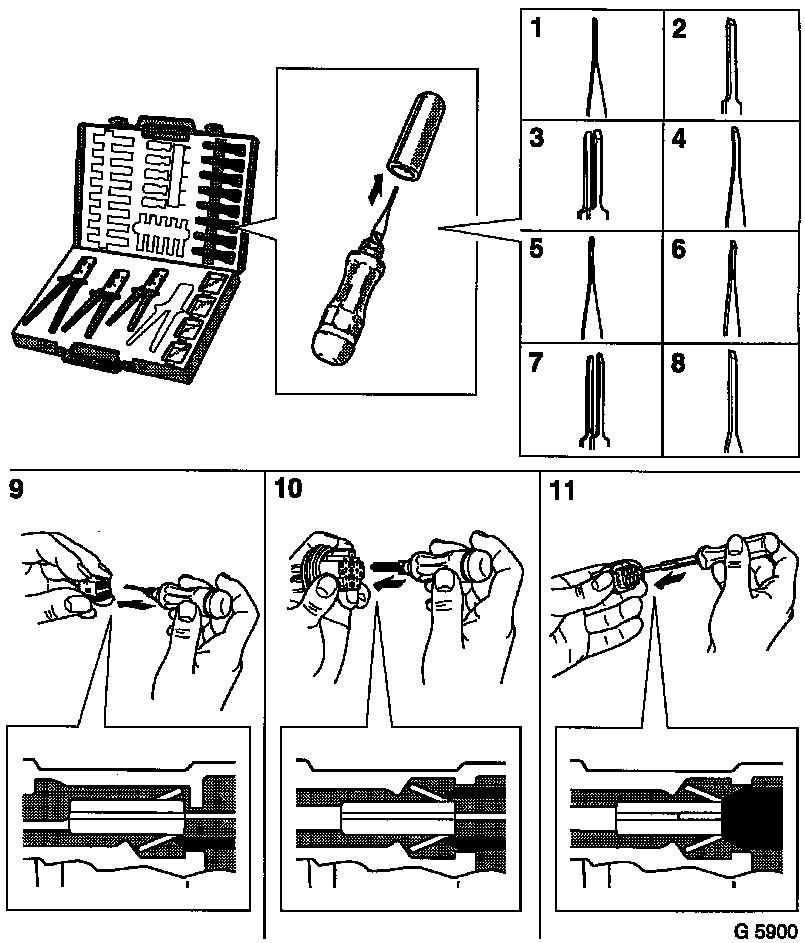

Step B - Prepare Special Service Tools, Materials B1 - Prepare special service tools The Special Service Tool Case MKM-923 contains the following tools and materials required for wiring harness repairs:

|

Position |

Designation |

Colour of handle |

For cable cross-section |

|

|

Crimping Pliers |

|

|

|

1 |

MKM-923-31 |

red |

0.5 / 0.75 / 1.0 mm 2 |

|

2 |

MKM-923-32 |

blue |

1.5 / 2.5 mm 2 |

|

3 |

MKM-923-33 |

yellow |

4.0 / 6.0 mm 2 |

|

4 |

Space for additional crimping pliers |

|

|

|

|

Detachment Tools |

|

5 |

Detachment Tools MKM-923-1 to MKM-923-8 for applications as of the introduction of the system. |

|

6 |

Space for additional detachment tools (round). |

|

7 |

Space for additional detachment tools. |

|

|

Container |

|

8 |

for cable connectors. |

Description of crimping pliers The crimping pliers are combined crimping and stripping pliers with the following features:

|

• Stripping position |

|

|

The crimping pliers have two stripping positions with a length stop (1) for the smallest cross-section, e.g. 0.5 mm 2 (2) and for all other cross-sections, e.g. 0.75 mm 2 and 1.0 mm 2 (3). The stripped length is matched to the relevant cable connector. |

|

|

|

|

|

• Crimp stamp |

|

|

During crimping, the marks "1" (red crimping pliers), "2" (blue crimping pliers) and "3" (yellow crimping pliers) are visible on the bottom of the cable connectors through the crimp cavity (4). The cable connectors are thus marked by the relevant crimping pliers on each application. |

|

• Handle colours |

|

|

The three handle colours red, blue and yellow indicate the application for the relevant cable cross-sections. |

|

|

|

|

|

|

These colours are reflected by the packaging of the cable connectors and shrink-down plastic tubing. The relevant crimping tool can thus be clearly allocated to the packaging of the cable connectors and the shrink-down plastic tubing. |

|

|

|

|

|

• Function features |

|

|

|

|

|

|

- |

Lock (5) to fix the connector in place when the cable is inserted. |

|

|

|

|

|

|

- |

The automatic pressure adjustment (6) with forced release (7) ensures optimal quality during the crimping operation once the set actuation pressure has been attained in the end position. |

|

|

|

|

|

|

- |

A releasable automatic lock (8) prevents damage to the pliers in the event of incorrect operation, e.g. when an oversized connector is inserted. To release, press the pliers and, at the same time, turn the release screw to the left with a screwdriver. |

Description of detachment tools Detachment tools have been developed to detach defective spring-finger connectors and cables. The tips of the detachment tools are specially designed to prevent damage to the wiring harness plug and spring-finger connector (1 to 8). In order to ensure that the plugs are correctly detached, select the detachment tools as specified in the parts and reference lists (see section 5).

|

• Detachment tool in case |

|

|

The case contains Detachment Tools MKM-923-1 (1) to MKM-923-8 (8). Detachment tools as of MKM-923-9 can be ordered as required and stored in the dedicated spaces in the case. |

|

|

|

|

|

• Tool types |

|

|

Three different types of detachment tool are included. These are suitable for spring-finger connectors |

|

|

|

|

|

|

- |

with one lock spring (9), |

|

|

- |

with two lock springs (10), |

|

|

- |

"round" (11). |

Important: The spring-finger connector being detached is pushed by the cable as far as possible into the casing. The detachment tool is then applied to the relevant chamber (9 to 11) until resistance can be felt. Remove spring-finger connector.

New detachment tools will be gradually developed along with the new applications and new spring-finger connectors.

B2 - Prepare materials Description of cable connectors and shrink-down plastic tubing Cable connectors and shrink-down plastic tubing can be ordered as replacement parts from the parts and reference lists (see section 5). The containers in the Case MKM-923 are intended for storage of the cable connectors.

|

Position |

Designation / cross-section |

Colour code |

Visual |

|

|

|

Packaging |

recognition features |

|

|

Cable connectors |

|

Stamp |

|

1 |

0.5 / 0.75 / 1.0 mm 2 |

red |

"1" |

|

2 |

1.5 / 2.5 mm 2 |

blue |

"2" |

|

3 |

4.0 / 6.0 mm 2 |

yellow |

"3" |

|

|

Shrink-down plastic tubing |

|

Imprint |

|

4 |

0.5 / 0.75 / 1.0 mm 2 |

red |

RBK-1 |

|

5 |

1.5 / 2.5 mm 2 |

blue |

RBK-2 |

|

6 |

4.0 / 6.0 mm 2 |

yellow |

RBK-3 |

The packaging for the cable connectors and shrink-down plastic tubing is red (7), blue (8) or yellow (9) for clear allocation to the handle colours of the corresponding crimping pliers.

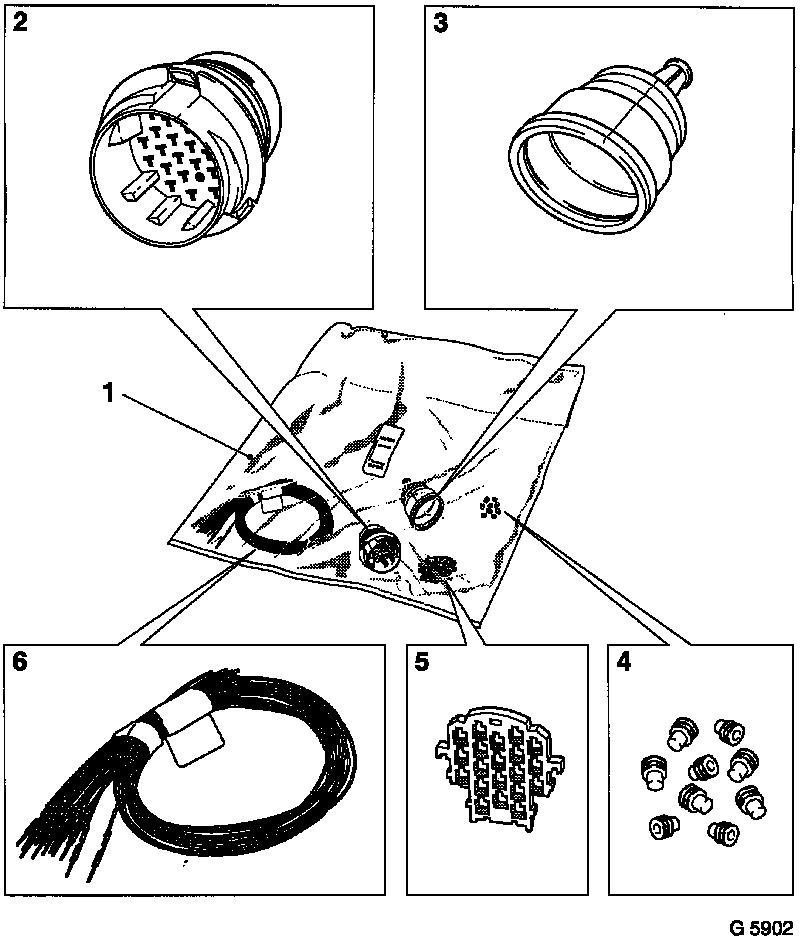

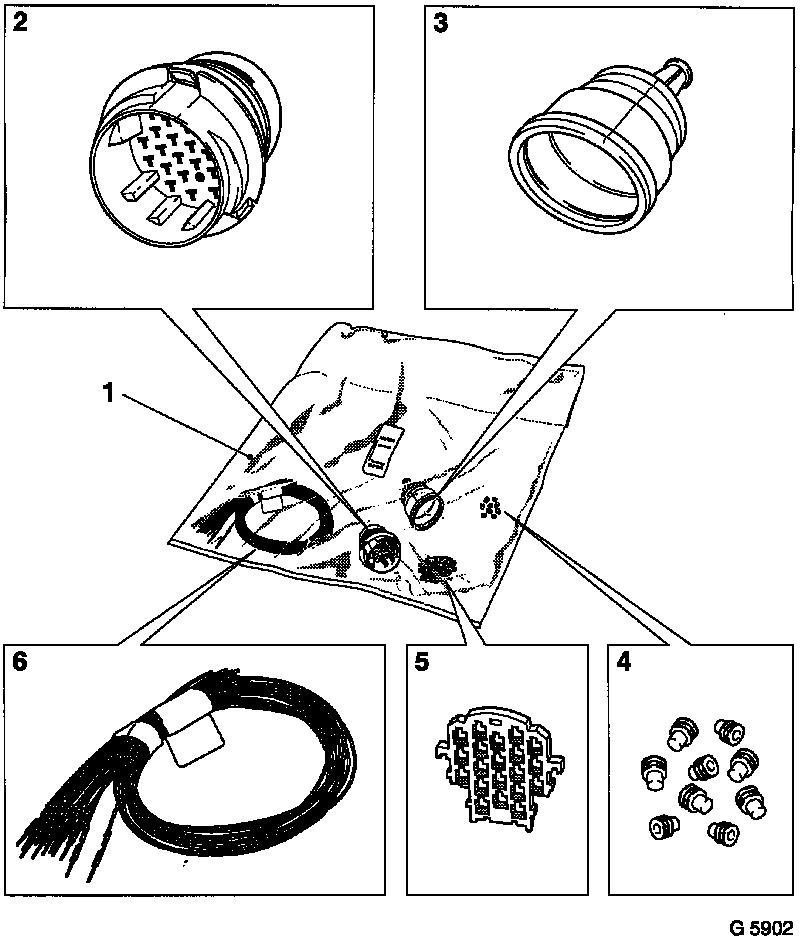

Description of wiring harness plugs with lead ends The wiring harness plugs with lead ends designed for wiring harness repairs are available as replacement parts from the "Service" department and are supplied as a complete package (1). The supplied items are:

|

• Wiring harness plug |

|

|

The wiring harness plugs (2) available for each model range are listed in section 5 - Survey of Wiring Harness Plugs and Reference Lists. |

|

|

|

|

• Rubber grommets |

|

|

If the rubber grommet (3) is difficult to slide onto the cable, coat the cable with silicone oil and carefully widen rubber grommet with commercially available expansion pliers. |

|

|

|

|

• Sealing plugs for water-tight wiring harness plugs |

|

|

Unoccupied chambers of the wiring harness plug must be fitted with the enclosed sealing plugs (4). |

|

|

|

|

• Secondary lock |

|

|

In wiring harness plugs with secondary lock (5), the lock spring on the spring-finger connector is solely intended to assist assembly. The spring-finger connectors are actually held in place by the secondary lock. |

|

|

|

|

• Spring-finger connectors with lead ends |

|

|

The lead ends (6) are always "white" to differentiate them from the standard production cables. |

Description of wiring harness plugs with lead ends

|

• Spring-finger connectors with lead ends (continued) |

|

|

The length of 50 to 75 cm allows the positions of the various crimpings to be varied when repairing several cables for one wiring harness plug, in order to largely retain the cross-section of the wiring harness as a whole. |

|

|

|

|

|

When replacing individual spring-finger connectors with lead ends, detach the relevant spring-finger connectors with the appropriate detachment tool from section 5 "Parts and Reference Lists" and connect the replacement spring-finger connectors in the standard wiring harness plug. |

Notice: As the wiring harness plugs designed for repairs are used in all models but with different cable assignments, it is possible that individual repair sets contain more cables than are required for the specific repair.

|