How to disassemble and reassemble the Differential in a Golf Mk1 5 speed gearbox

|

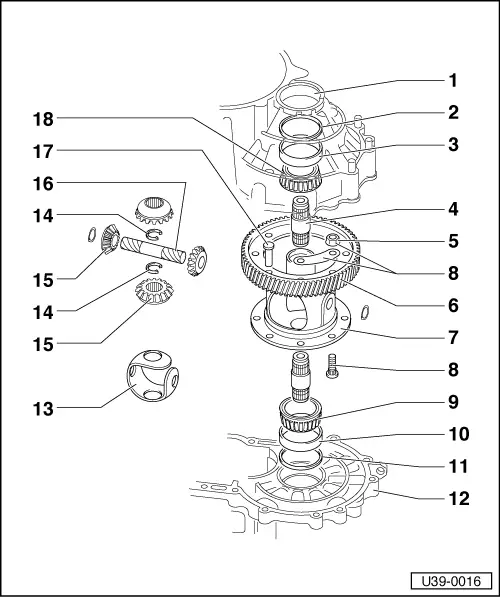

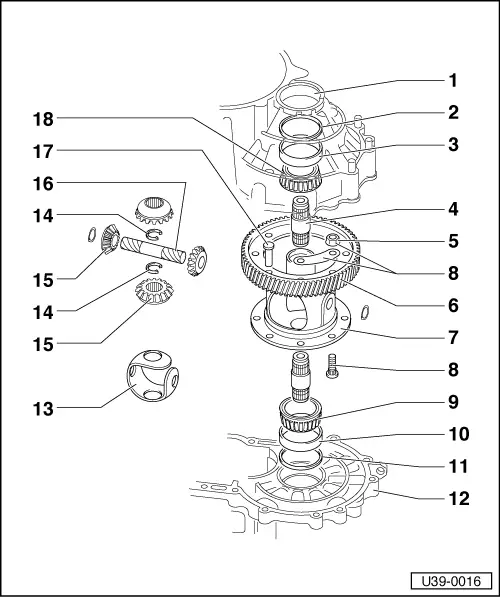

Final drive, Differential

Dismantling and assembling differential

|

|

|

|

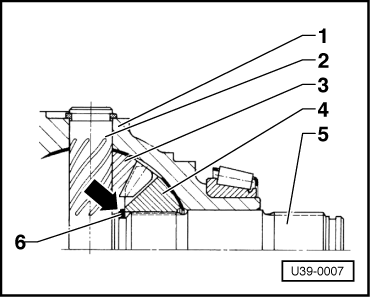

Differential bevel gear shaft secured with extended rivets Play free location of drive flange shafts => page 39-19 Caution!

The inner and outer races of the taper roller bearings are matched and must not be interchanged. |

|

|

|

|

|

|

|

|

|

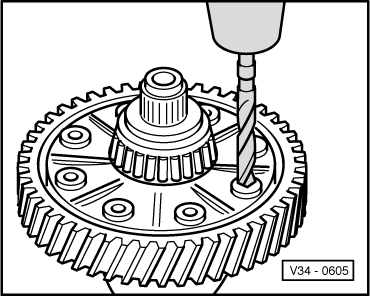

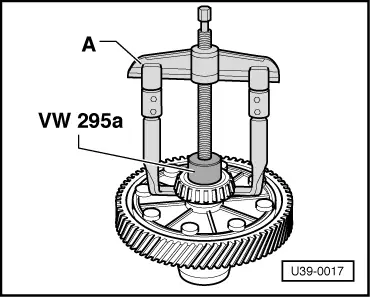

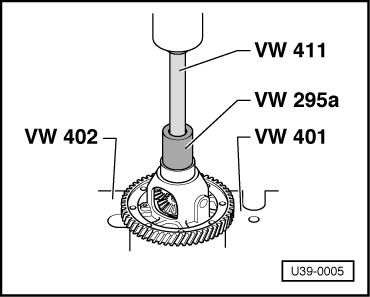

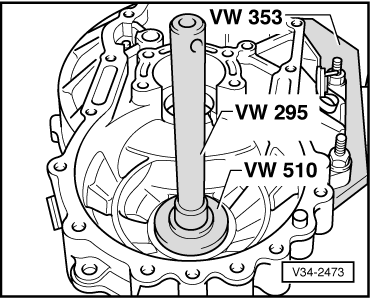

→ Fig.1 Pulling inner race off

|

|

|

|

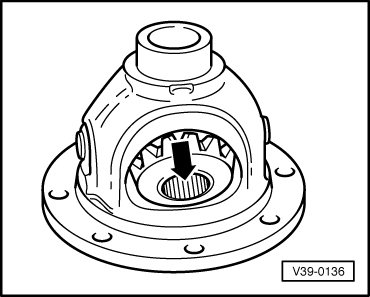

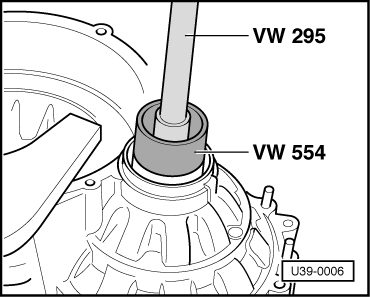

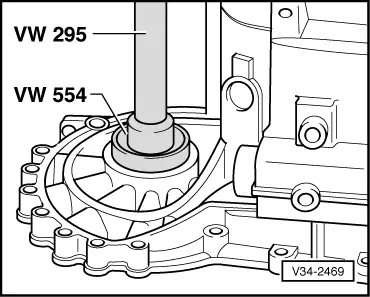

→ Fig.2 Pressing inner race home Heat race to 100° first and install. |

|

|

|

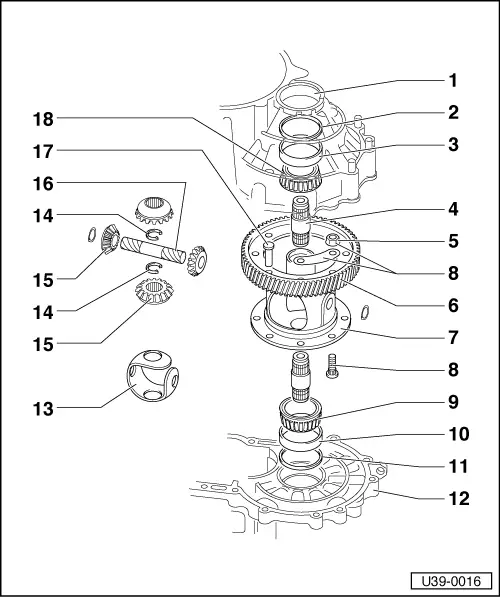

→ Fig.4 Pressing crown wheel off |

|

|

|

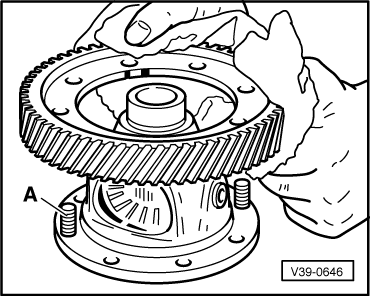

→ Fig.5 Heat crown wheel to about 100° C and install Guide crown on the housing with screws -A- from repair kit. |

|

|

|

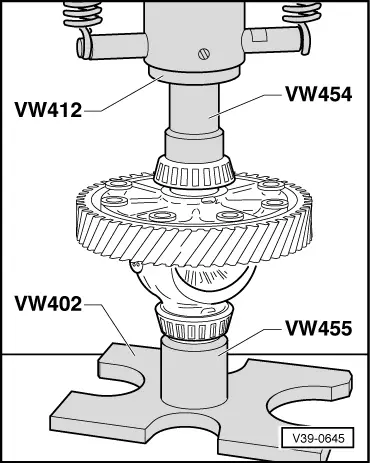

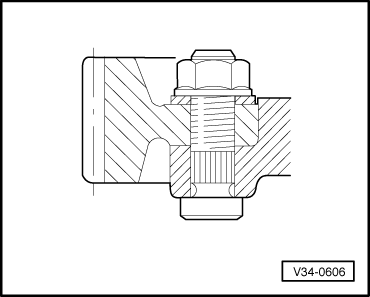

→ Fig.6 Bolt crown wheel to housing with special screws, washers and nuts - Part No. 171 498 088 (Repair Kit). |

|

|

|

→ Fig.9 Knocking differential bearing outer race out of bearing housing |

|

|

|

→ Fig.10 Knocking differential bearing outer race into bearing housing |

|

|

|

→ Fig.11 Knocking differential bearing outer race out of gearbox housing |

|

|

|

→ Fig.12 Knocking differential bearing outer race into gearbox housing |