Adjusting Output Shaft for Golf Mk1 5 Speed Manual Gearbox 020

|

Gears, Shafts

Adjusting output shaft

(Finding thickness of "S3" shim) The output shaft must be adjusted if

have been replaced. |

|

|

|

See also "Adjustment list",

|

|

|

Caution!

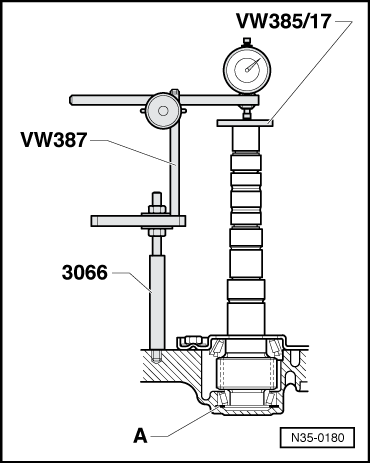

Do not turn the shaft when measuring because the bearings will then settle and give an incorrect reading. Finding thickness of S3 shim The specified bearing preload is obtained by adding a constant figure (0.20 mm) to the measured reading (0.30 mm) and the shim thickness (0.65 mm) for S3. |

|

|||||||||||||||||||||||||||||||||||||||||||||||||||

The following shims are available:

Different tolerances make it possible to select the exact thickness of shims required.

| |||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

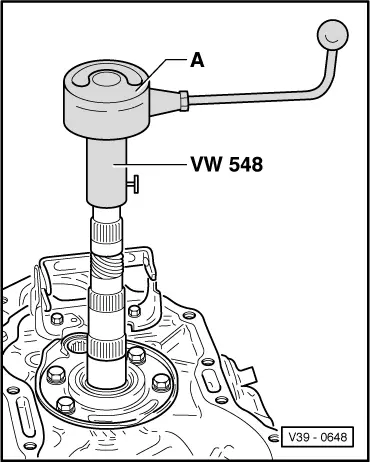

→ A = Torque gauge 0 - 600 Ncm Checking turning torque This should be 50-150 Ncm for new bearings. The turning torque on bearings which have been in use should be at least 30 Ncm. Lubricate bearings beforehand with hypoid gear oil. |