Golf Mk1

|

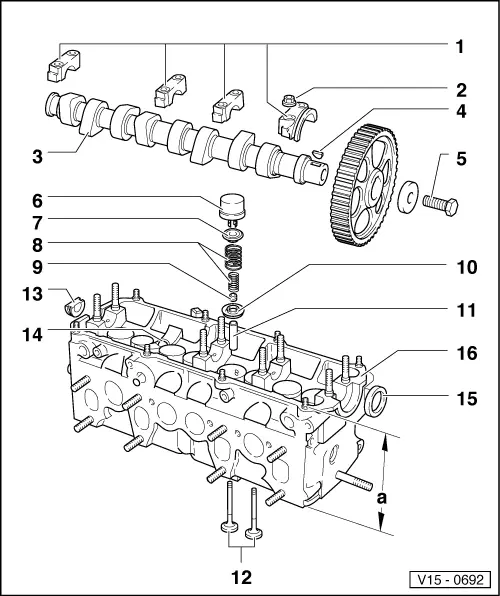

Servicing valve gear

Servicing valve gear

|

|

|

|

Note: Cylinder heads which have cracks between the valve seats or between a valve seat insert and the spark plug thread can continue to be used without reducing service life, provided that the cracks do not exceed a max. width of 0.5 mm or when no more than the first spark plug threads are cracked.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

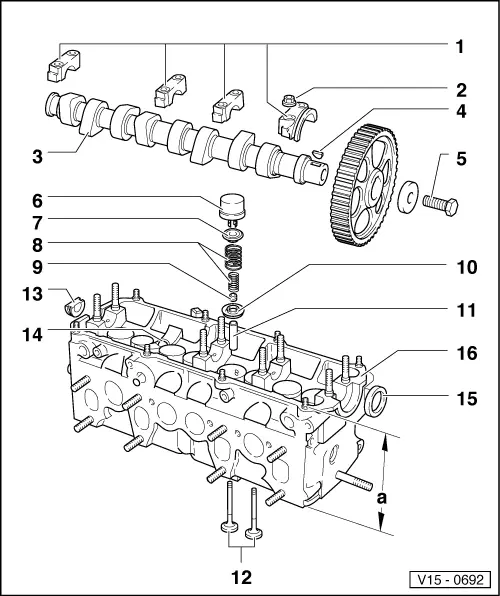

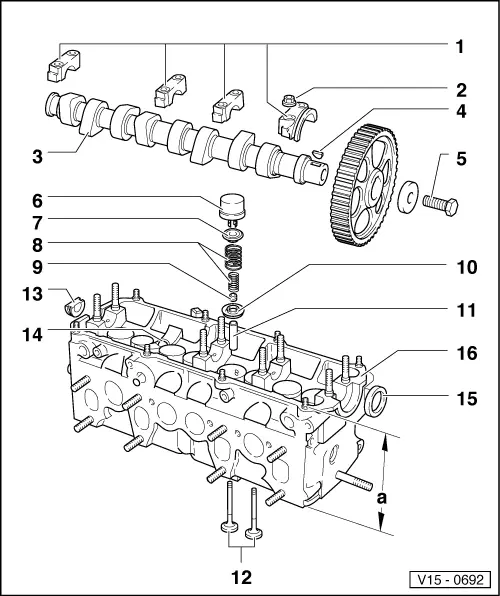

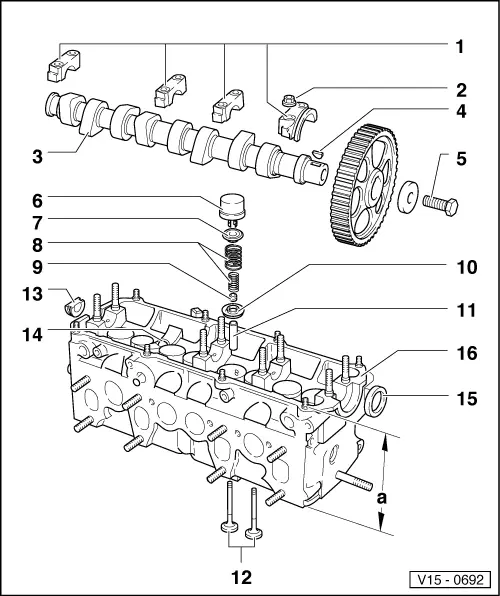

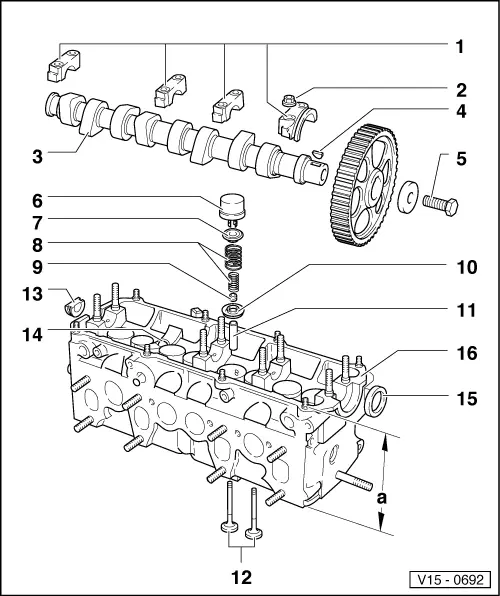

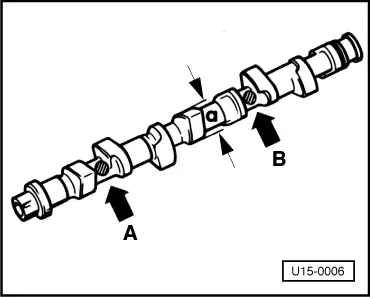

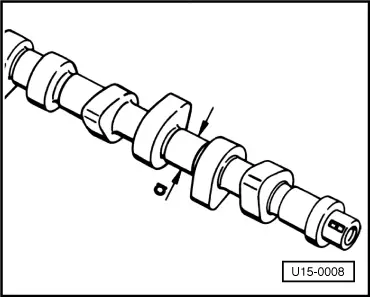

→ Fig.1 Checking axial clearance of camshaft Wear limit: 0.15 mm Measure with bucket tappets removed and first and last bearing caps installed. |

|

|

|

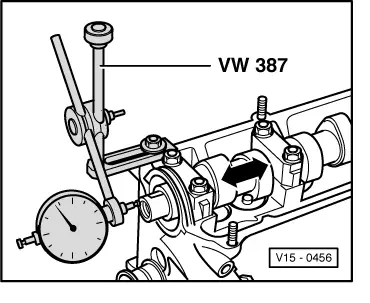

→ Fig.2 Installation position of camshaft bearing caps Note centre offset. Before installing camshaft, mount bearing caps and determine installation position. |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

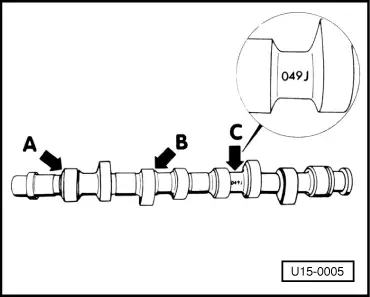

→ Fig.4 Camshaft identification, valve timing Identification with hydraulic bucket tappets

Valve timing with 1 mm valve stroke

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||

|

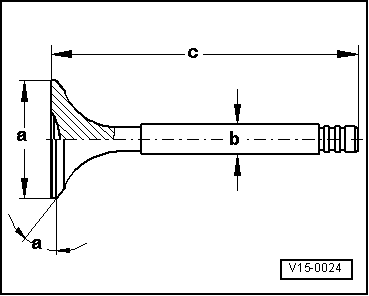

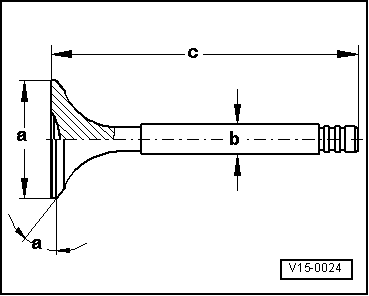

→ Fig.5 Valve dimensions Note: Valves are not to be reworked. Only grinding is permitted.

1) Engine codes HM ä 01.97 only |

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(with hydraulic valve clearance compensation)

|

|

|

|

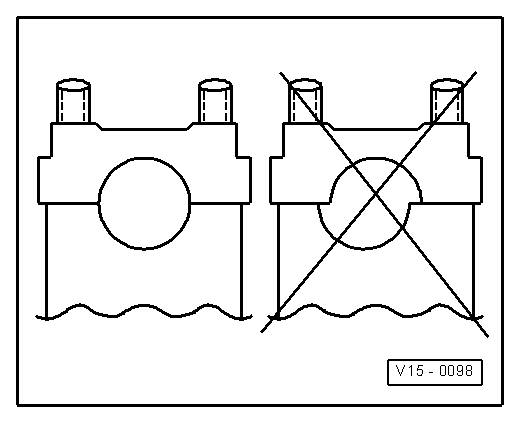

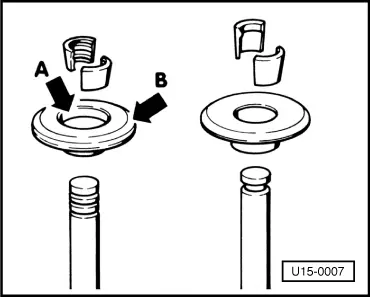

→ Fig.6 Valve types 05.81 ä installation of valves with 3 grooves Distinguishing features

Note: When performing repairs, 1 and 3-groove valves can be mixed. It is to be noted that the respective valves are only to be installed with the envisaged valve tapers and valve spring seats. |

|

|

|

→ Fig.7 Exchange cylinder heads with camshaft bearing shells Exchange cylinder heads/exchange engines are sometimes supplied with bearing shells for camshafts.

Note: Undersize camshafts are not supplied as replacements. For repairs, install a standard size camshaft with corresponding bearing shells. |