|

Engine oil specification

Use engine oils as per VW Standard 500 00 or 501 01. Exceptional circumstances only: multi-grade/single grade oils as per API-SF or SG.

Oil capacity1)

|

|

with

filter

|

without

replacement

|

|

ä 07.85

|

3.5 l

|

3.0 l

|

|

08.85 ä

|

4.0 l

|

3.5 l

|

1)

Current values => "Exhaust gas and idling speed test binder"

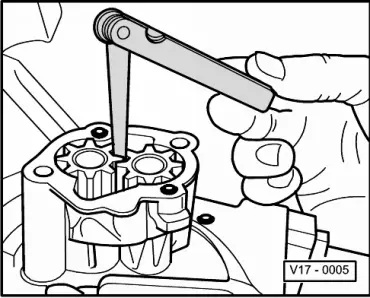

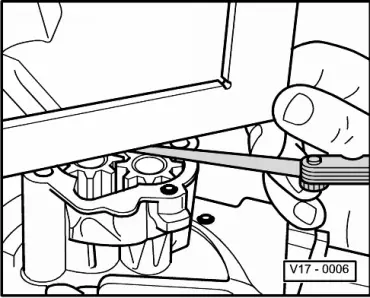

Checking oil pressure: checking oil pressure switch and oil pressure

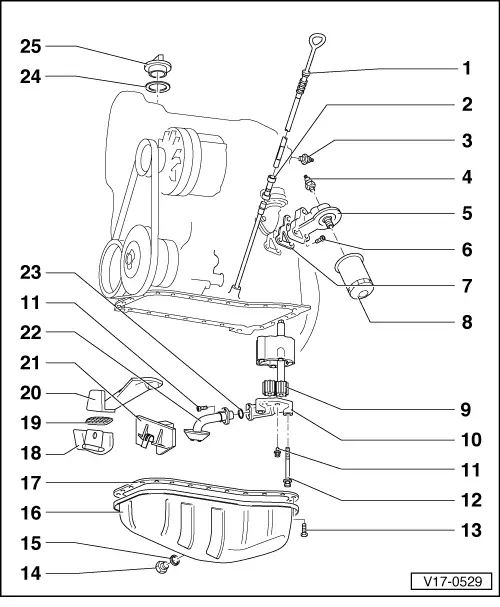

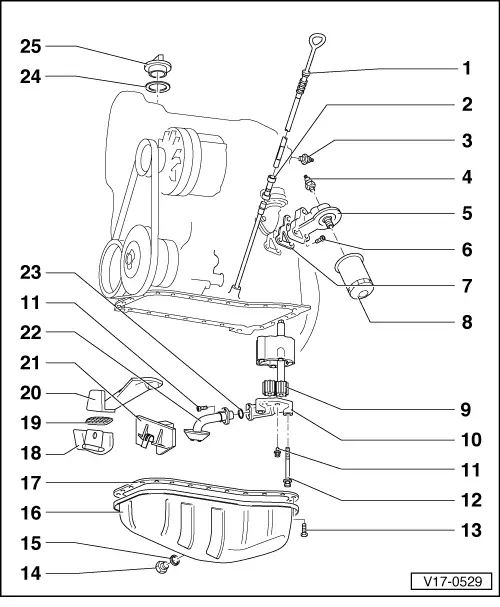

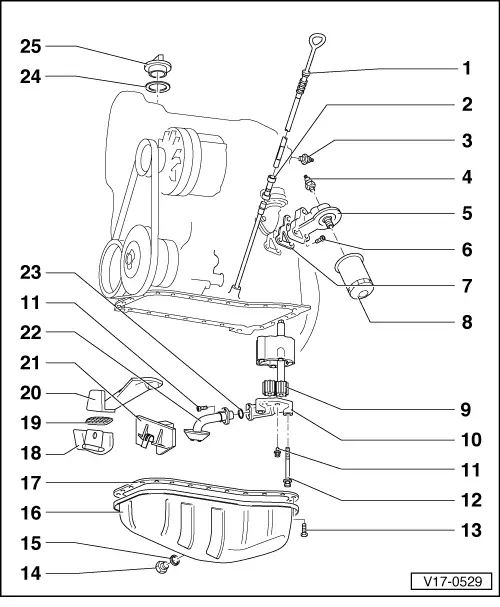

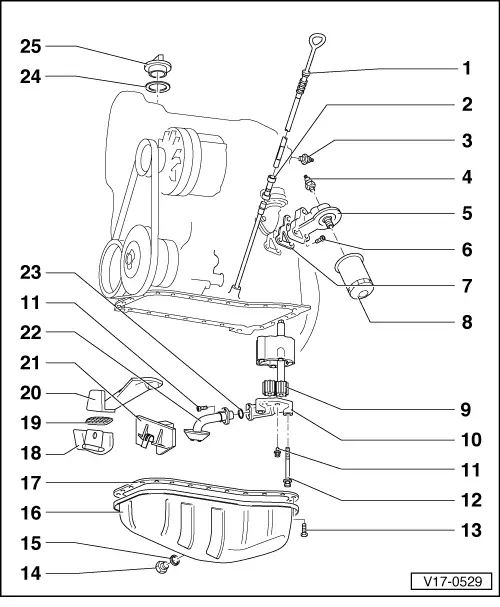

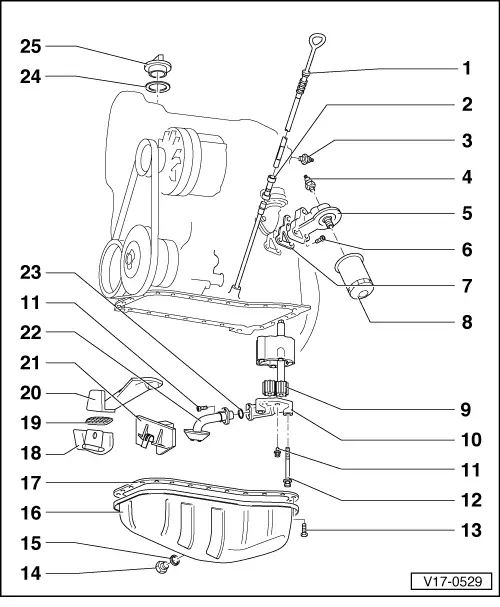

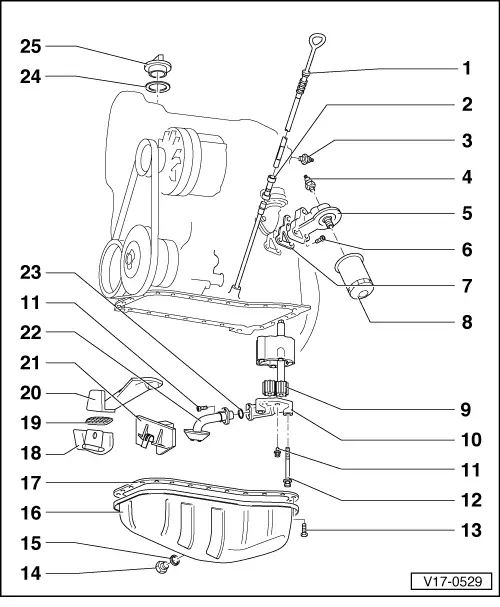

- Oil dipstick

-

◆ Quantity difference min/max

Round dipstick = 1 l

Flat dipstick = 0.75 l

- Dipstick guide

-

◆ 08.89 ä

-

◆ Remove to draw off oil

|