Golf Mk1

|

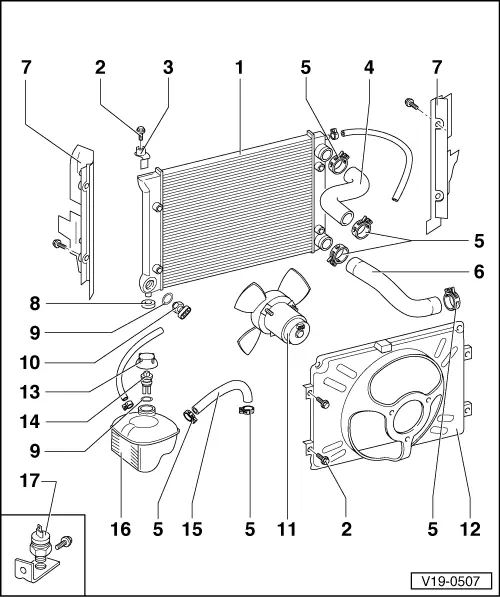

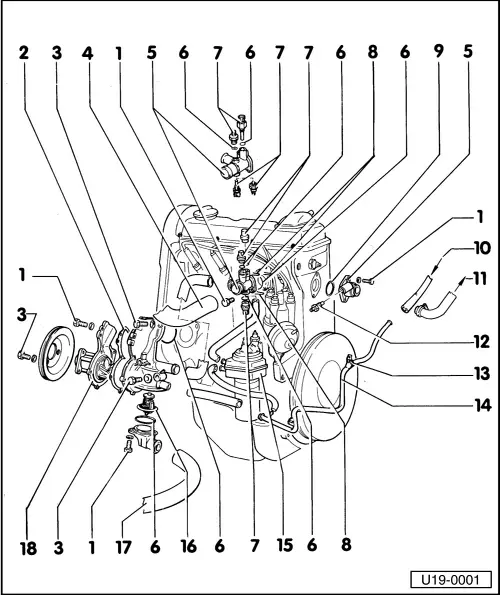

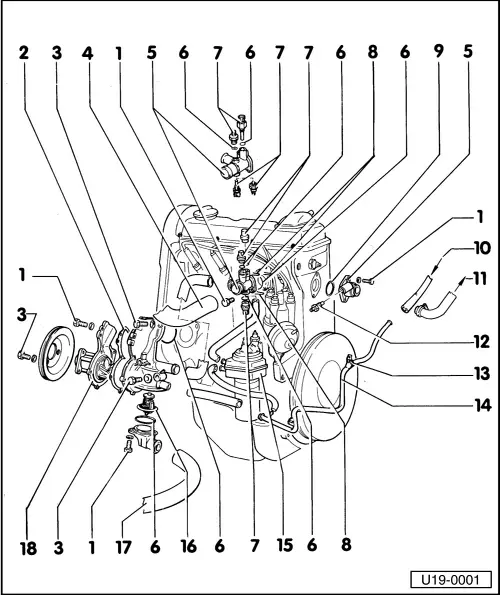

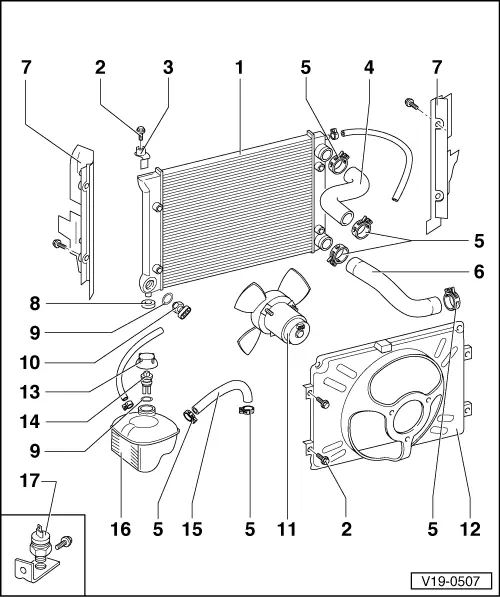

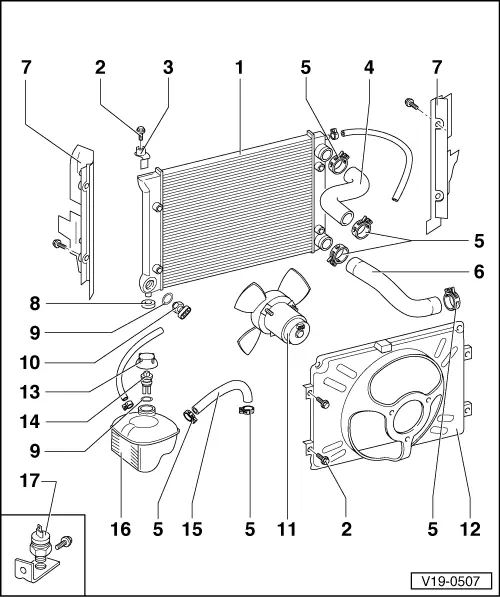

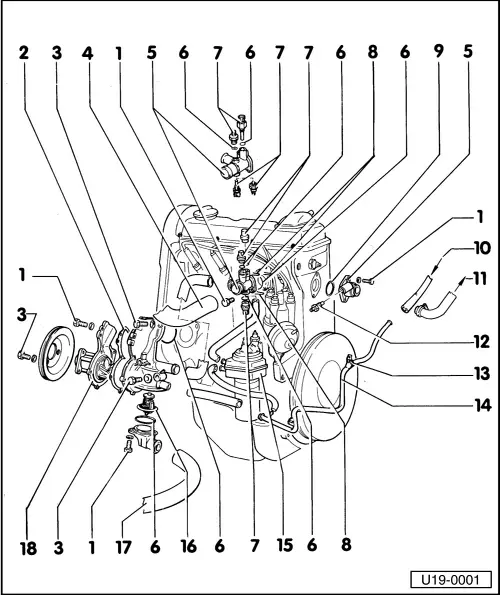

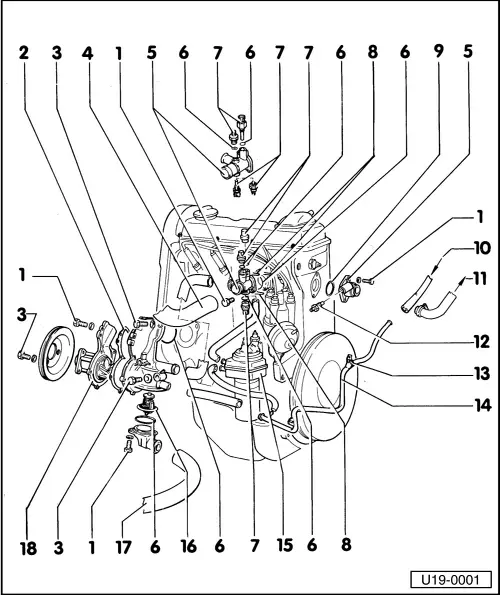

Removing and installing cooling system components

Removing and installing cooling system components

|

|

|

Notes:

|

|

|

|

|

|||||||||||||||

| |||||||||||||||

|

|

|

|

|

|

Notes:

|

|

|

|

|

|

|

|

|

|

|

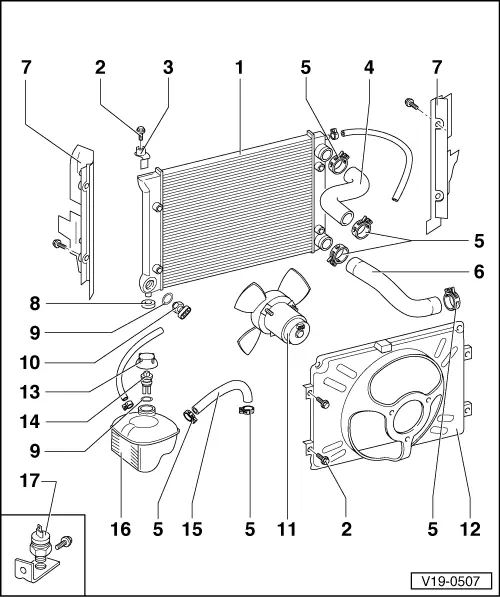

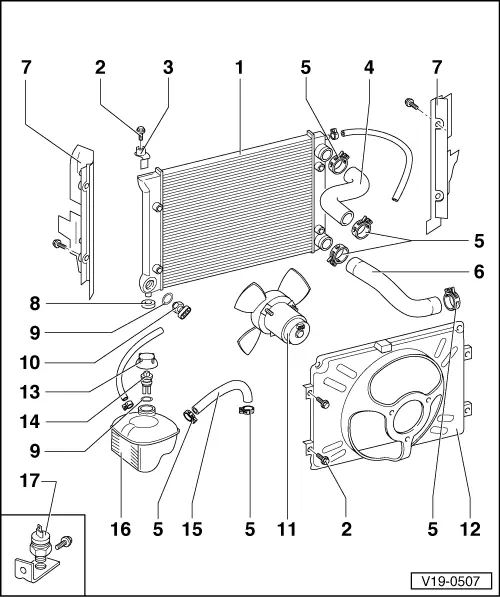

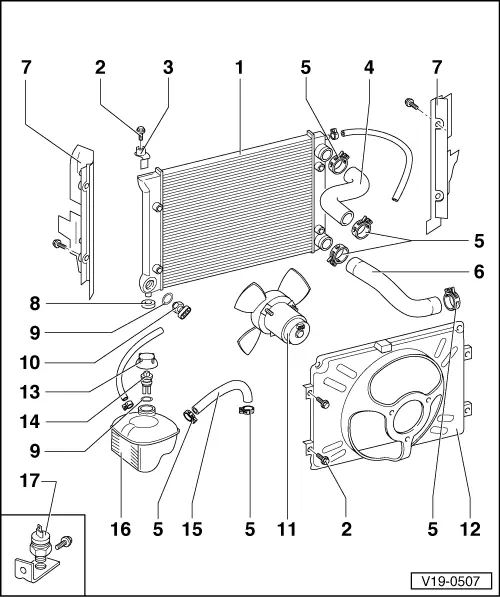

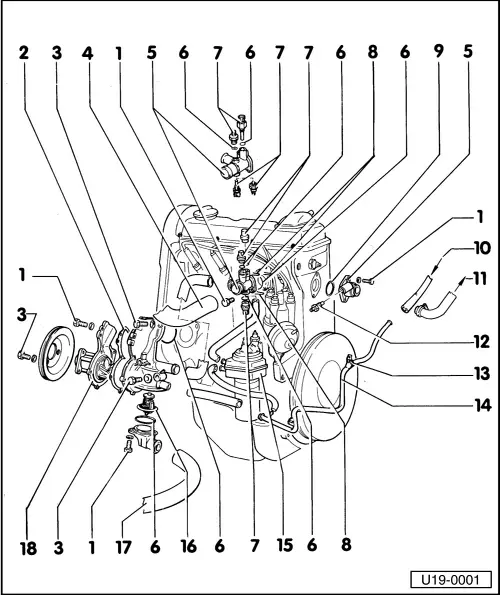

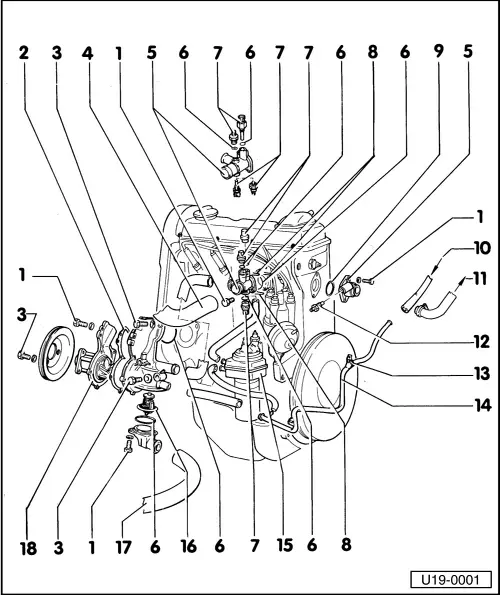

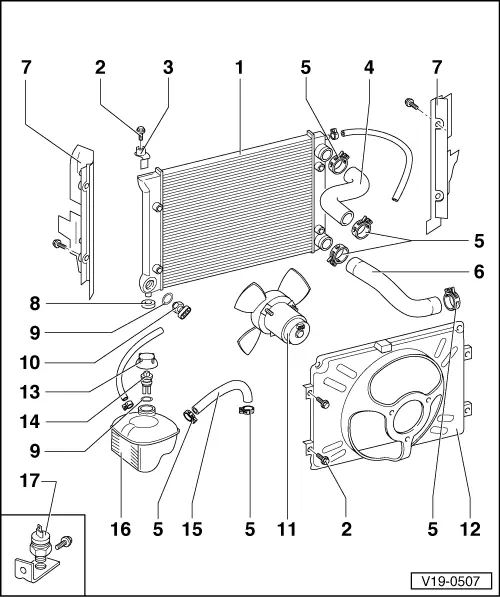

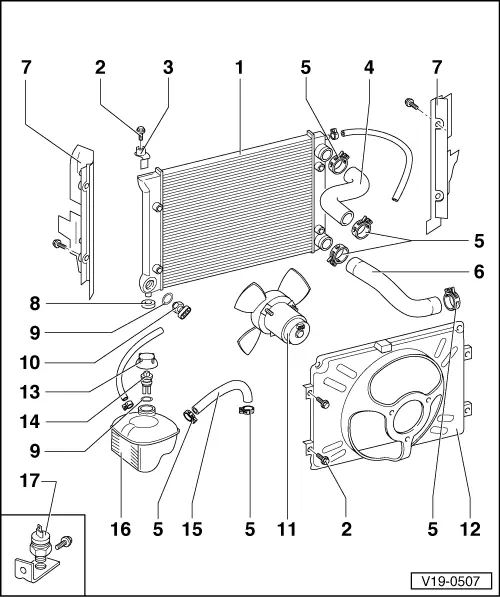

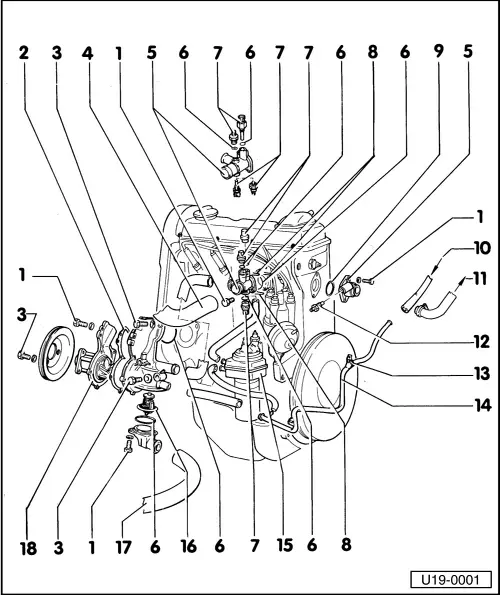

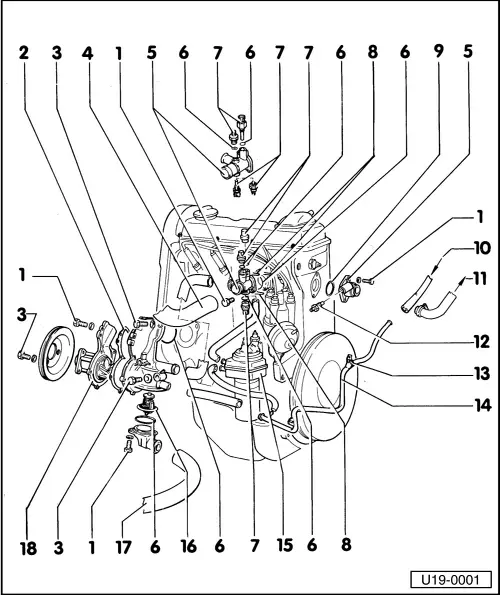

Removing and installing cooling system components

Removing and installing cooling system components

|

|

|

Notes:

|

|

|

|

|

|||||||||||||||

| |||||||||||||||

|

|

|

|

|

|

Notes:

|

|

|

|

|

|

|

|

|

|