-

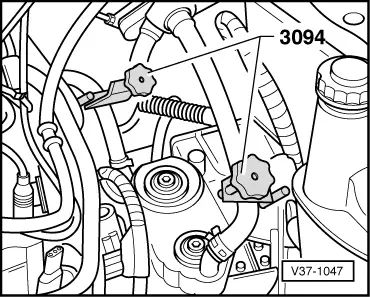

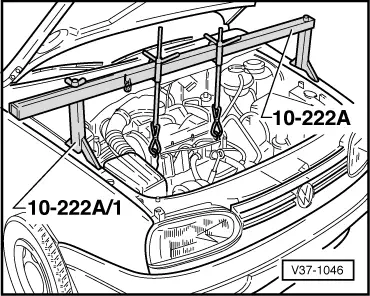

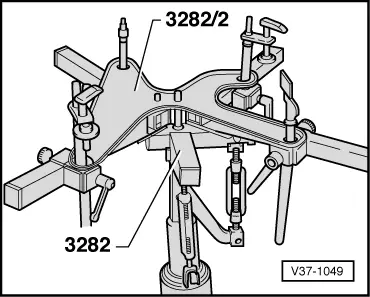

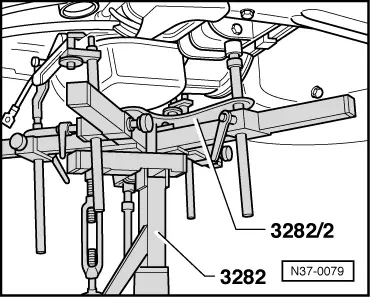

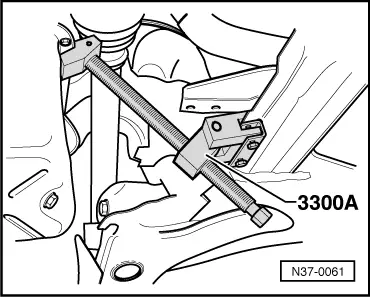

‒ → Tilt engine and gearbox forwards with supporting device 3300 A.

-

‒ Press gearbox off engine; when doing this, press torque converter out of drive plate.

-

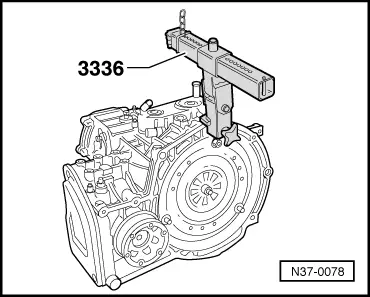

‒ Press torque converter against ATF pump.

-

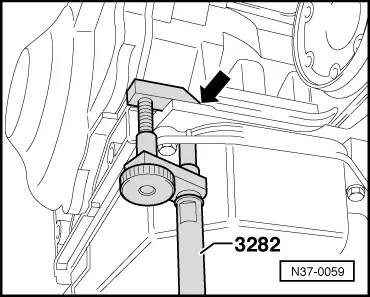

‒ Lower engine using support device spindle.

-

‒ Lower gearbox slightly.

-

‒ When doing this guide the power assisted steering pressure pipe past the gearbox.

-

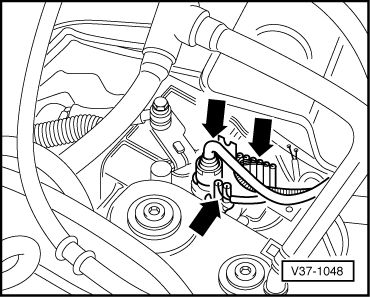

‒ Tilt gearbox using gearbox jack spindle and whilst lowering ensure cover (wheel housing side) is guided closely past wheel housing.

-

‒ Swivel gearbox and carefully lower.

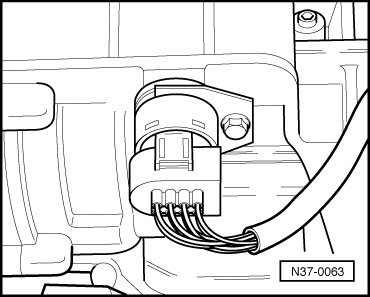

Ensure that the right joint flange does not contact the supporting device 3300 A and that the multi-function switch does not contact the subframe.

-

‒ Secure torque converter to prevent it falling out.

Installing

Installation is performed in the reverse order.

When installing the torque converter, ensure that both drive pins engage in the ATF pump inner wheel recesses.

-

‒ Before installing, ensure that the dowel sleeves are correctly located.

-

‒ When installing gearbox, observe torque converter contact impression on drive plate.

-

‒ Replace selector cable anchorage locking washer.

-

‒ Check selector lever cable adjustment, adjust if necessary .

Tightening torques

Drive shaft to flange |

45 Nm |

Torque converter to drive plate |

60 Nm |

Gearbox to engine bolt M 12 |

80 Nm |

Gearbox to engine bolt M 10 |

60 Nm |

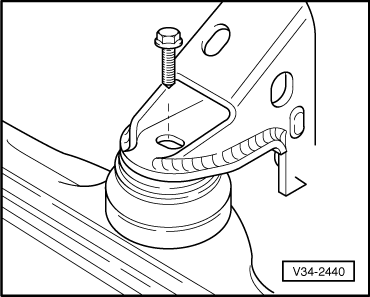

Front console to assembly mounting |

60 Nm |

Left console to assembly mounting |

60 Nm |

Left console to gearbox |

25 Nm |

Cover plate to gearbox |

15 Nm |

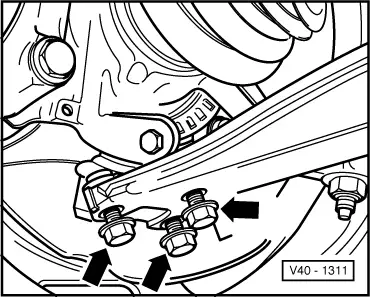

Ball joint to wishbone |

35 Nm |

Starter to gearbox |

60 Nm |

|