Golf Mk3

|

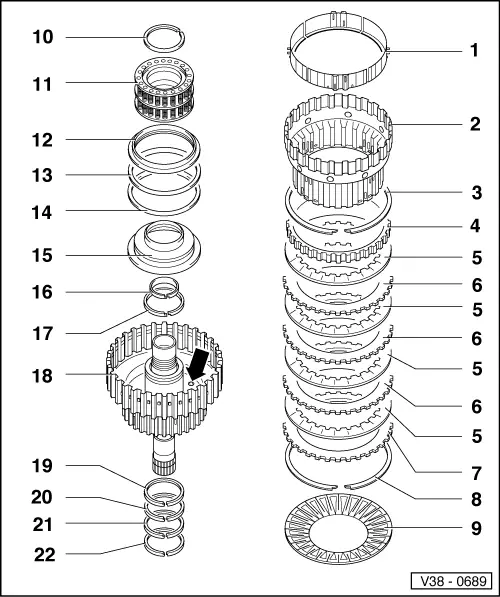

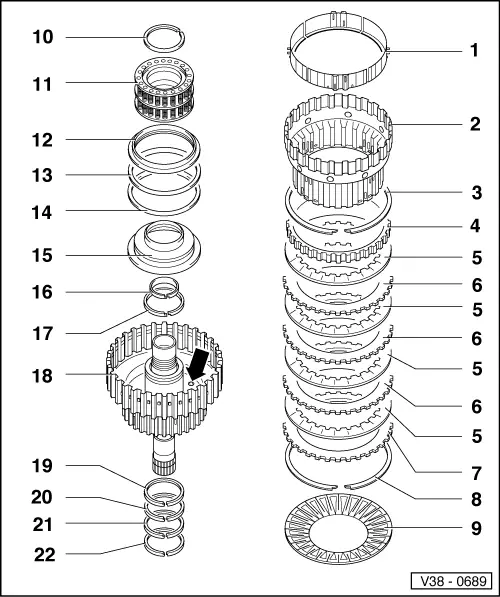

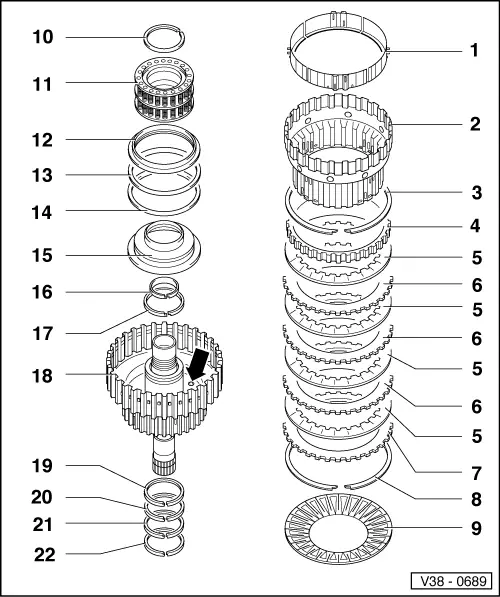

Dismantling and assembling 1st to 3rd gear clutch -K1- with turbine shaft on gearboxes up to 12.92

Dismantling and assembling 1st to 3rd gear clutch -K1- with turbine shaft on gearboxes up to 12.92

|

|

|

|

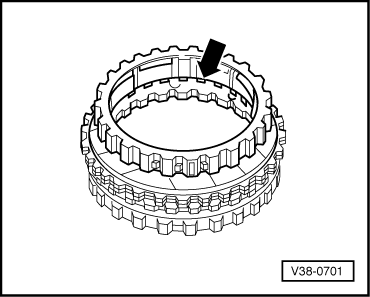

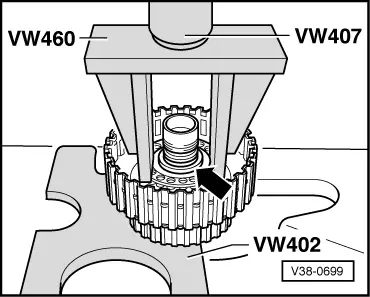

Gearboxes up to 12.92 Note: When performing repairs to the clutch, ensure that the ball valve (arrow) is not damaged. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

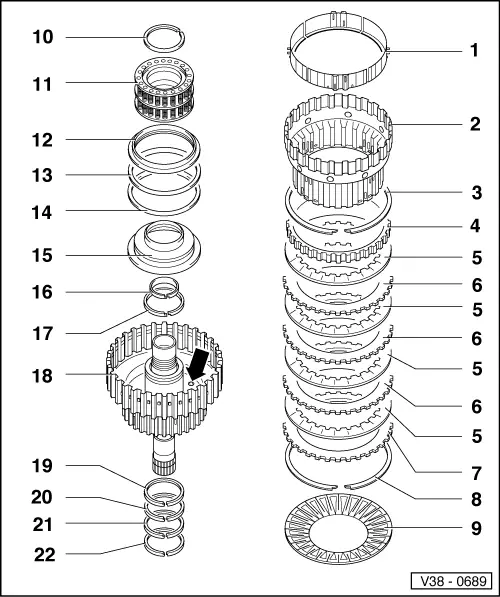

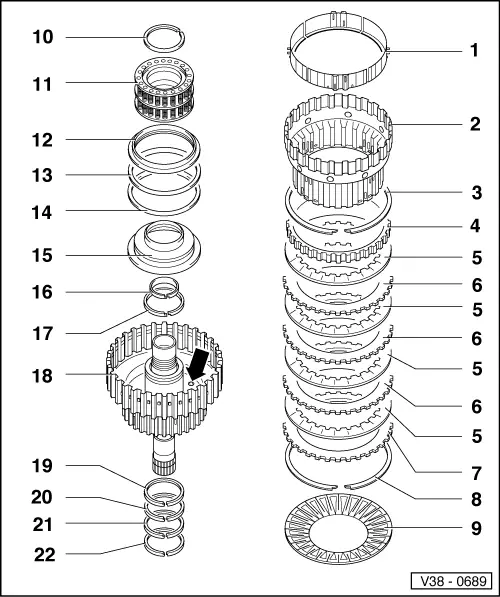

→ Fig.1 Installation position of disc springs

|

|

|

|

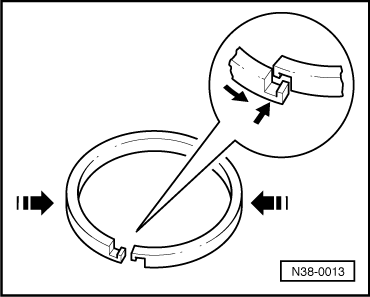

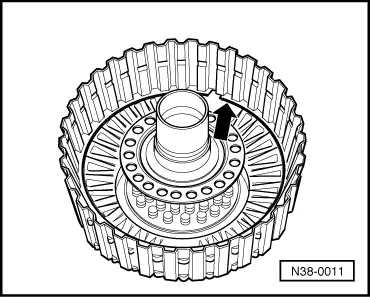

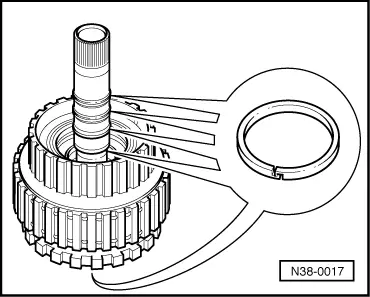

→ Fig.2 Removing and installing circlip

|

|

|

|

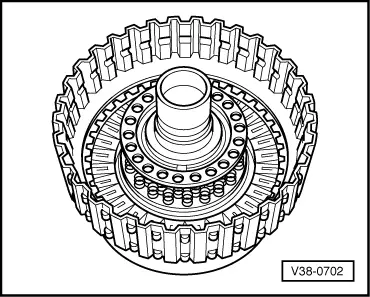

→ Fig.3 Inserting circlip

|

|

|

|

→ Fig.5 Inserting pressure plate, first inner and first outer plate into clutch housing |

|

|

|

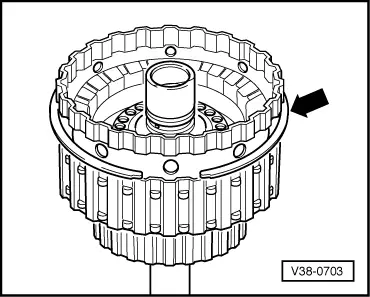

→ Fig.6 Inserting inner plate carrier and installing circlip (arrow)

|

|

|

|

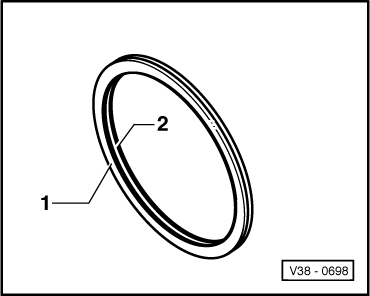

→ Fig.7 Checking seating of piston rings There are two piston rings installed on the turbine shaft inside the clutch housing.

|