Golf Mk3

|

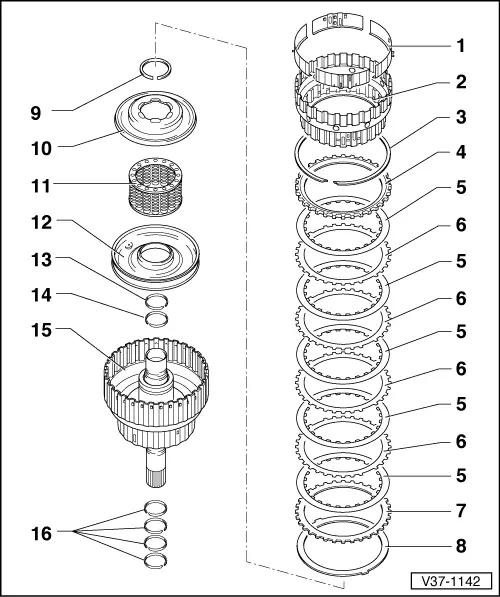

Dismantling and assembling 1st to 3rd gear clutch -K1- with turbine shaft on gearboxes up to 12.92

Dismantling and assembling 1st to 3rd gear clutch -K1- with turbine shaft on gearboxes from 01.93

|

|

|

|

Gearboxes from 01.93 |

|

|

|

|

|

|

|

|

|

|

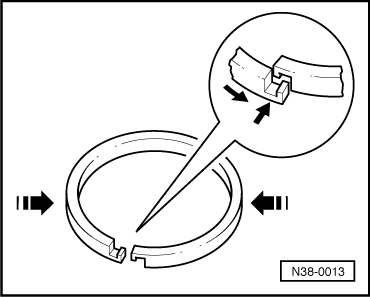

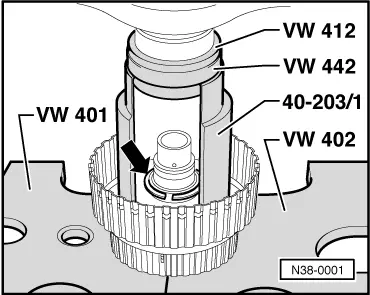

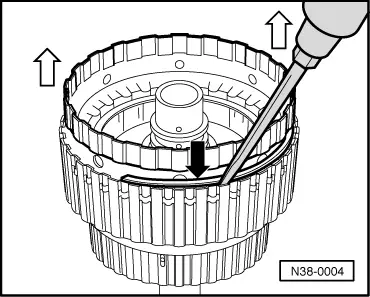

→ Fig.1 Removing and installing circlip

|

|

|

|

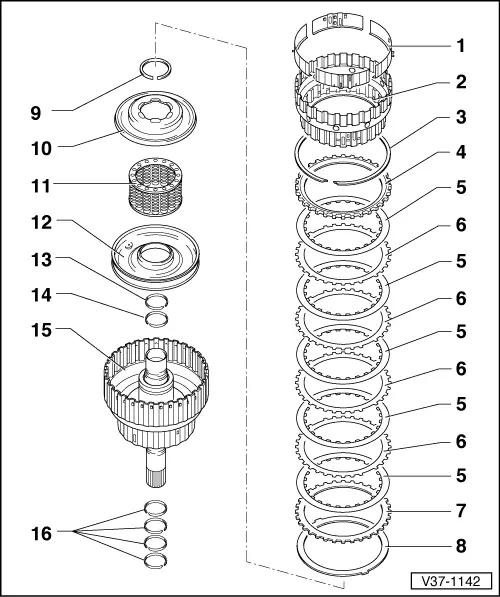

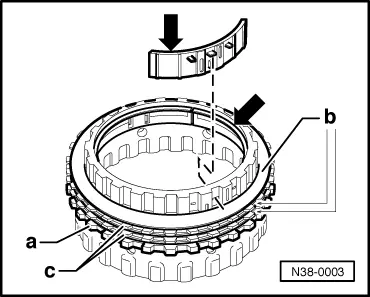

→ Fig.2 Fitting thrust plate and plates onto inner plate carrier

Notes:

|

|

|

|

→ Fig.3 Installing corrugated washer and inner and outer plates in clutch housing

|

|

|

|

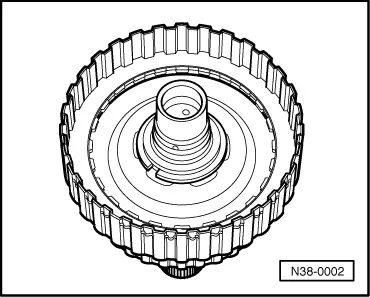

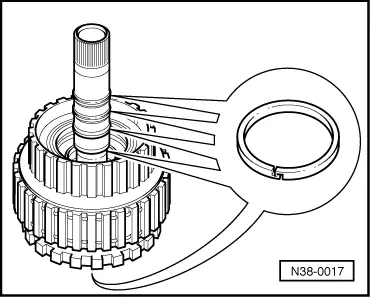

→ Fig.4 Inserting inner plate carrier and installing circlip (arrow).

|

|

|

|

→ Fig.5 Checking seating of piston rings There are two piston rings installed on the turbine shaft inside the clutch housing.

|