Golf Mk3

|

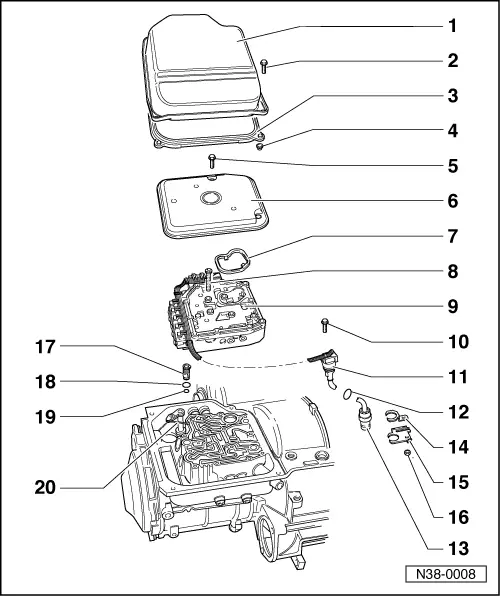

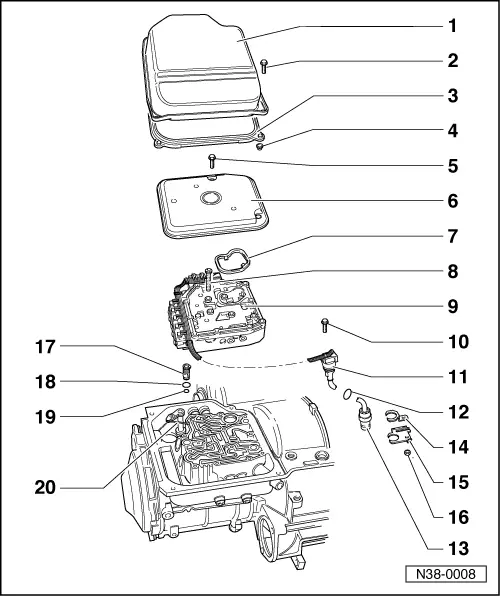

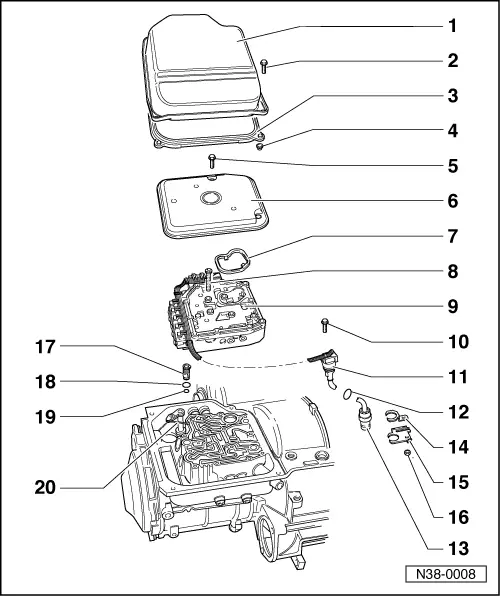

Removing and installing valve body

Removing and installing valve body

|

|

|

|

|

|

|

|

|

|

|

|

|

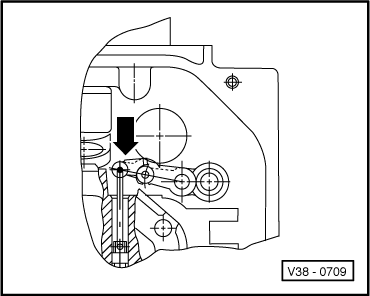

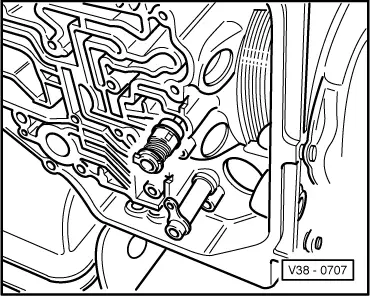

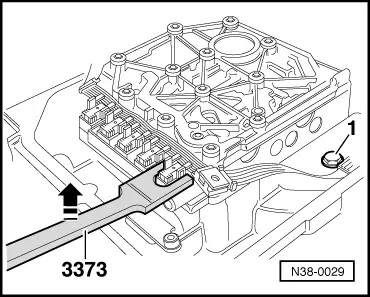

→ Fig.1 Inserting sealing plug Pull sealing plug out of housing before removing and installing free wheel otherwise the sealing plug and the O-ring will be damaged. |

|

|

|

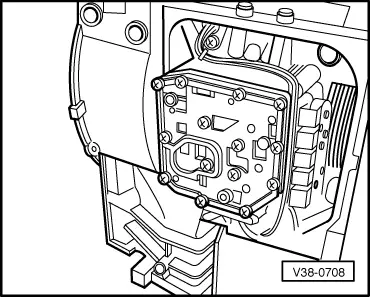

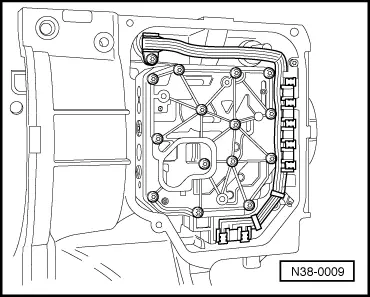

→ Fig.2 Installing valve body with wiring loom |

|

|

|

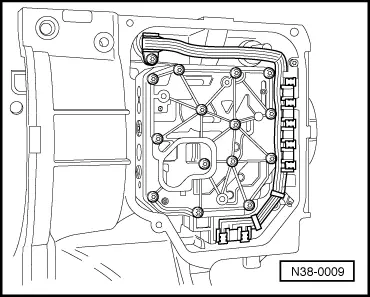

→ Fig.3 Installing with conductor strip

|

|

|

|

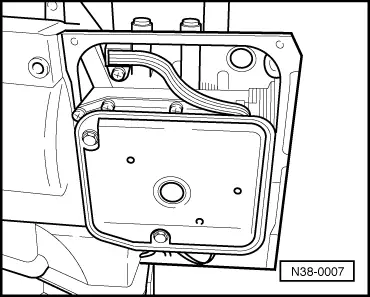

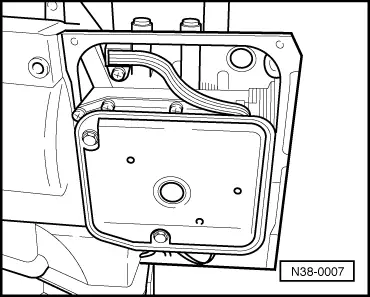

→ Fig.5 Installing ATF screen

|

|

|

|

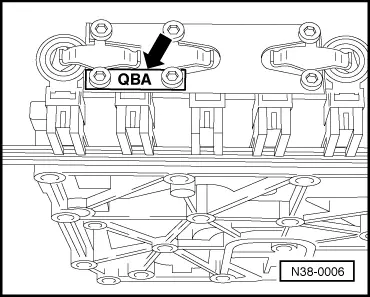

→ Fig.6 Identification of valve body Code letters are stamped on a metal tab. Metal tab must remain on the valve body. Allocation valve body/gearbox =>from Page 00-3 Note: If the valve body does not have an identification tab, it can remain allocated to the gearbox. When replacing valve body, ensure correct allocation =>from Page 00-3. Removing and installing conductor strip with sender for gearbox oil temperature (ATF) -G93- Location: The conductor strip is located in the oil pan on the valve body. The conductor strip can be changed with gearbox installed without removing the valve body. Removing

|

|

|

|

|

|

Note: If the locating points are damaged the valve body must be exchanged. Installing |

|

||||||

Tightening torques

|