Golf Mk3

|

Removing and installing bevel box

Removing and installing bevel box (Vehicles with 6-cylinder injection engine)

Special tools, testers and auxiliary items

Removing

|

|

|

|

|

|

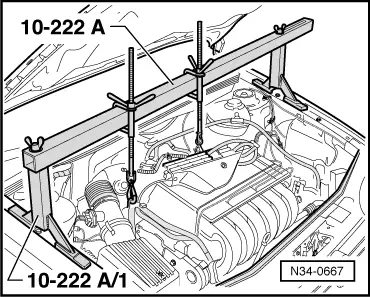

Note: Before fitting the support hooks of the support bar, remove hose and wire connections from engine in the area of the lifting eyes, so that they are not damaged.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Warning!

Always wear protective glasses.

=> Repair group 26; Removing and installing parts of exhaust system, four wheel drive. |

|

|

|

|

|

|

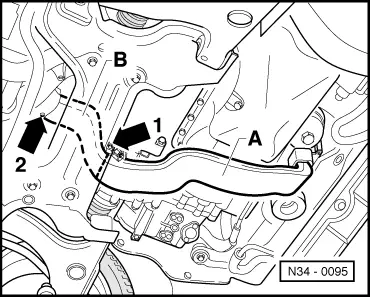

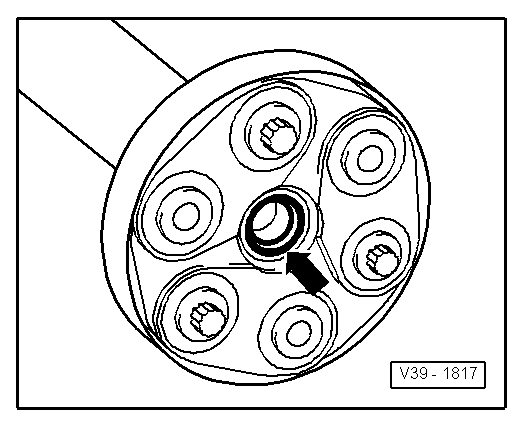

Note: → When removing and installing the gearbox do not damage the sealing ring in the propshaft flange.

|

|

|

|

=> Repair group 10; removing and installing engine. Notes:

|

|

|

=> Running gear; Repair group 40; Servicing drive shaft

=> Repair group 26; Removing and installing parts of exhaust system.

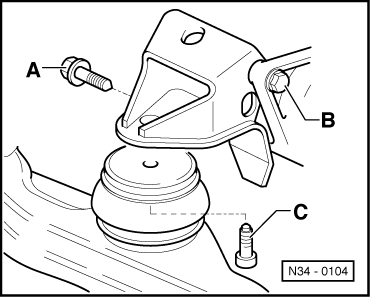

Tightening torques =>from Page 34-51 |