Golf Mk3

|

Servicing valve gear

Removing and installing camshaft

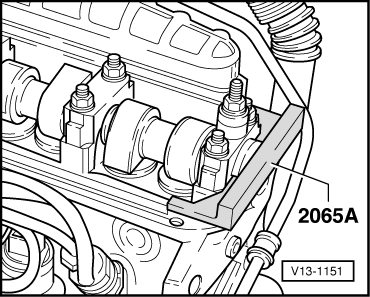

Special tools, workshop equipment, testers, measuring instruments and auxiliary items required |

|

|

Removing

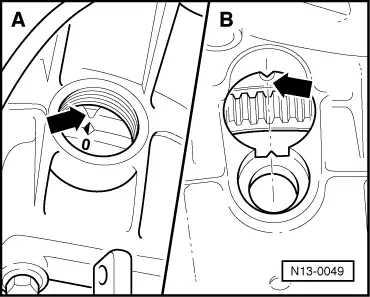

Engines with semi-automatic tensioning roller:

|

|

|

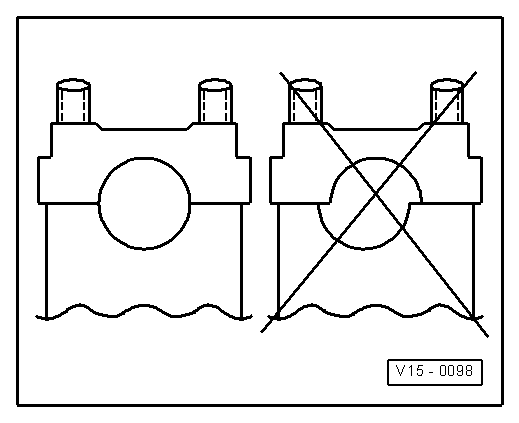

Installing |

|

|

|

Notes:

Note: When new tappets have been installed the engine must not be started for about 30 minutes. Hydraulic compensation elements must settle (otherwise valves will strike pistons). |