Golf Mk3

|

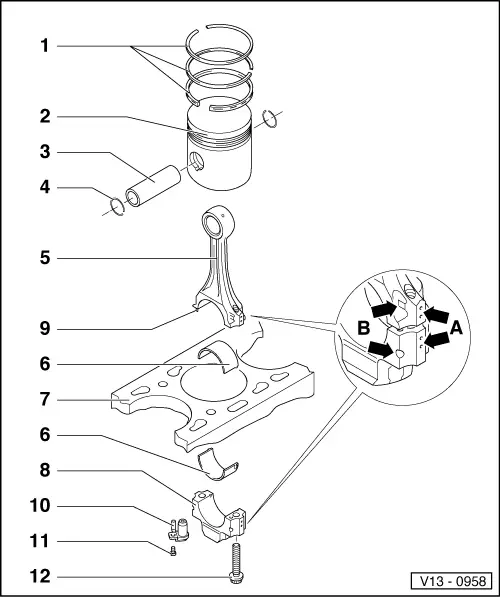

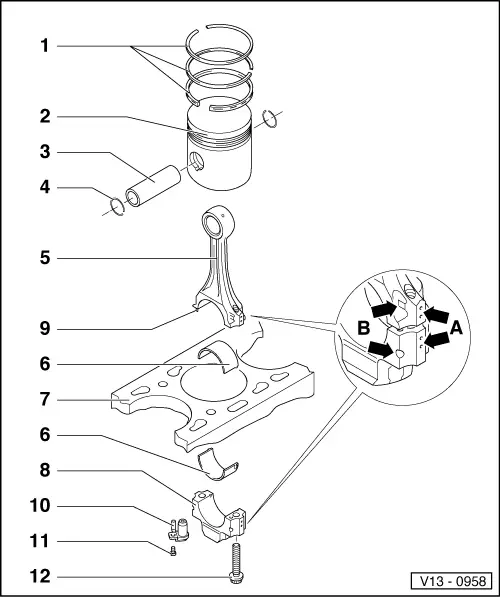

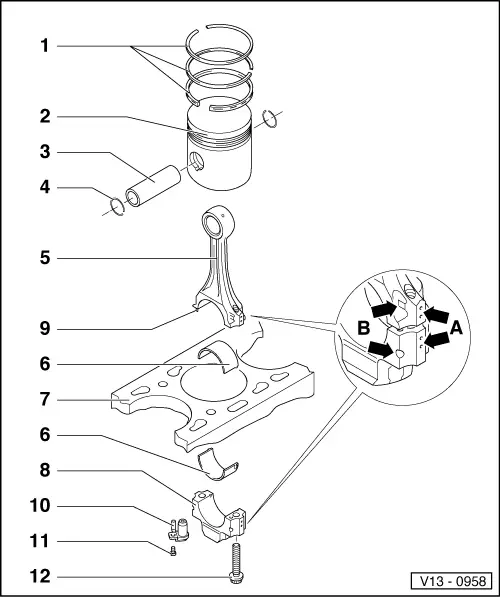

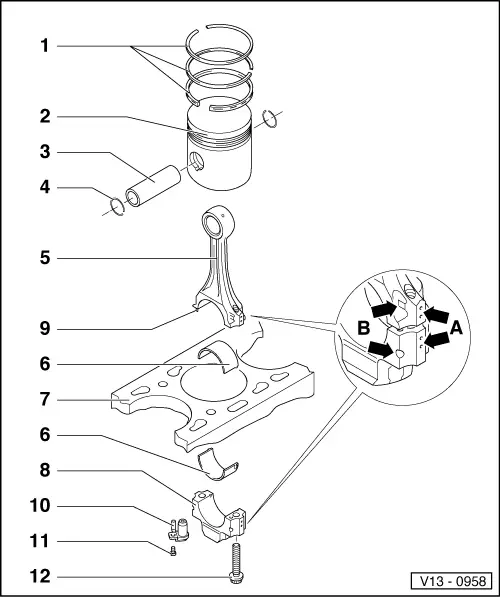

Dismantling and assembling pistons and conrods

Dismantling and assembling pistons and conrods

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

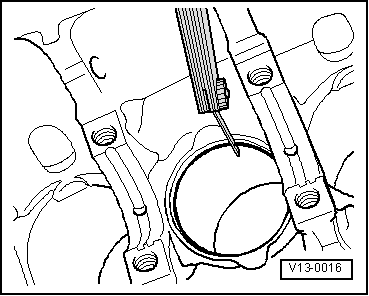

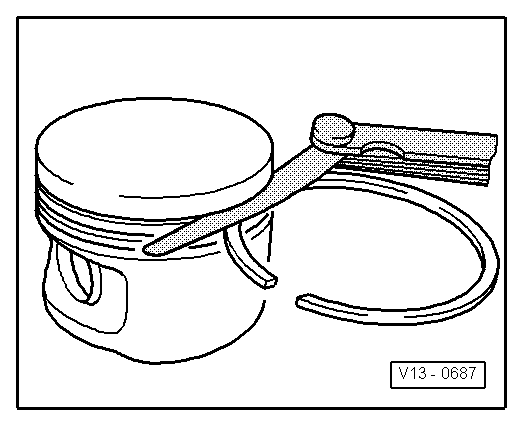

→ Fig. 2 Checking ring to groove clearance Clean groove before check.

|

|

|

|

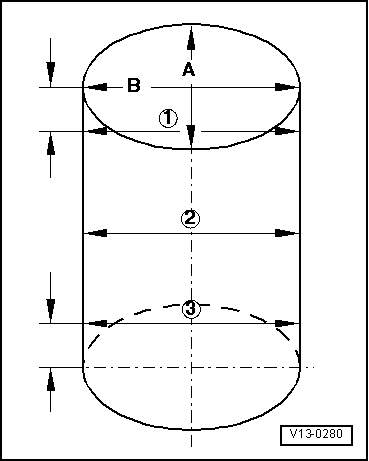

→ Fig. 3 Checking cylinder bores Special tools, workshop equipment, testers, measuring instruments and auxiliary items required

Note: Measuring the cylinder bores must not be done when the cylinder block is mounted on a repair stand with adapter bracket VW 540, as incorrect measurements would then be possible. |

|

|

|

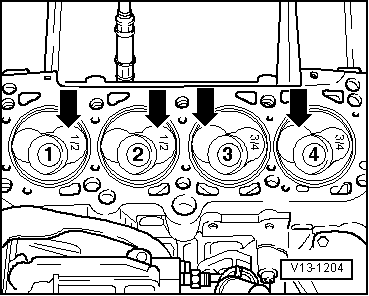

→ Fig.4 Piston installation position and piston/cylinder allocation Piston in cylinders 1 and 2: Larger inlet valve chamber towards flywheel -arrows- Piston in cylinders 3 and 4: Larger inlet valve chamber towards belt pulley side -arrows-. Note: New piston allocation to cylinders is shown by a coloured marking on piston crown.

|