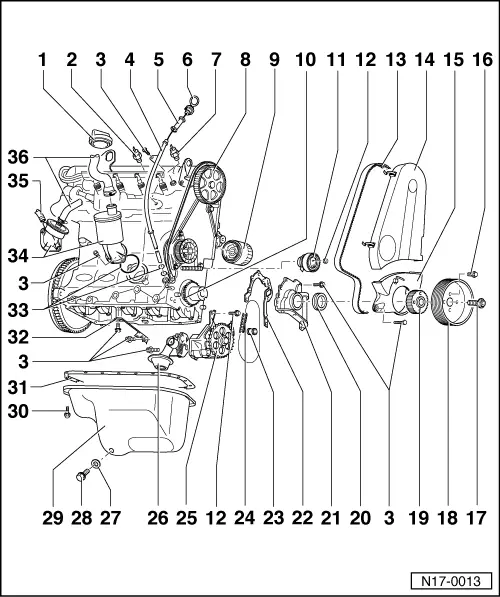

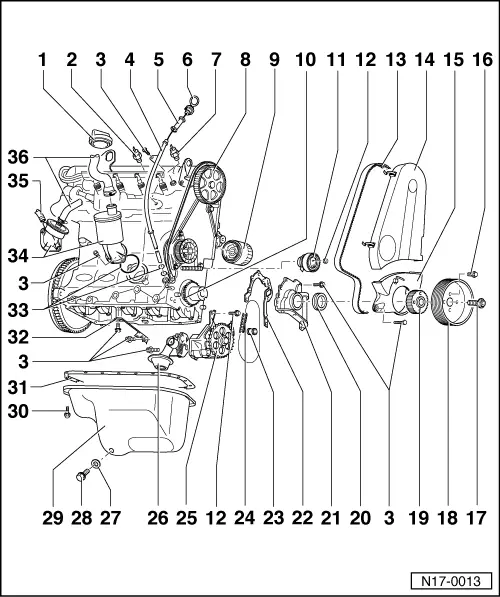

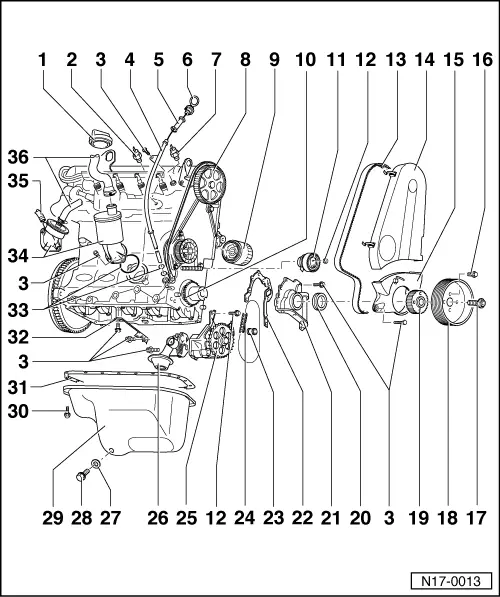

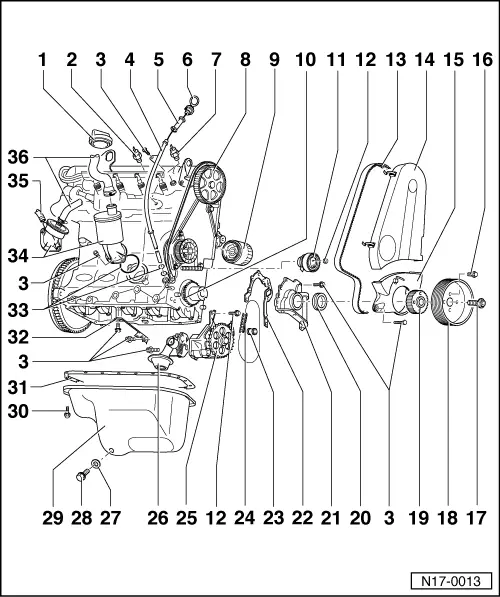

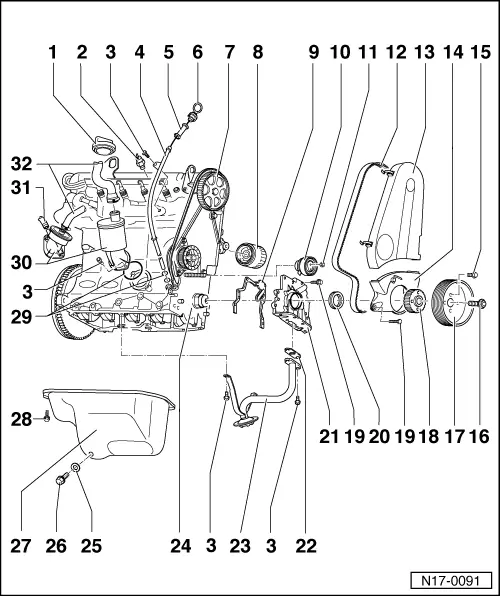

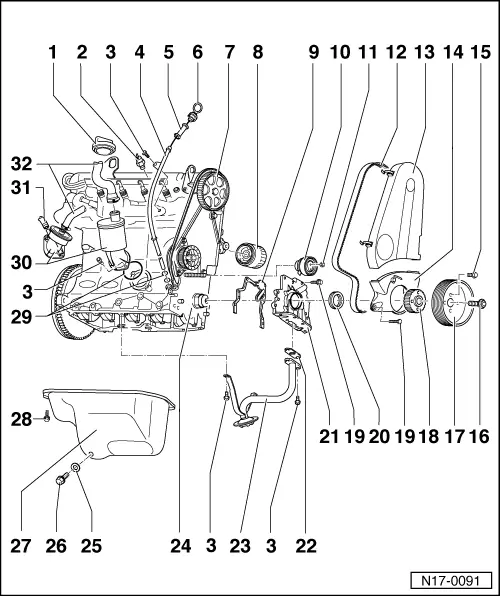

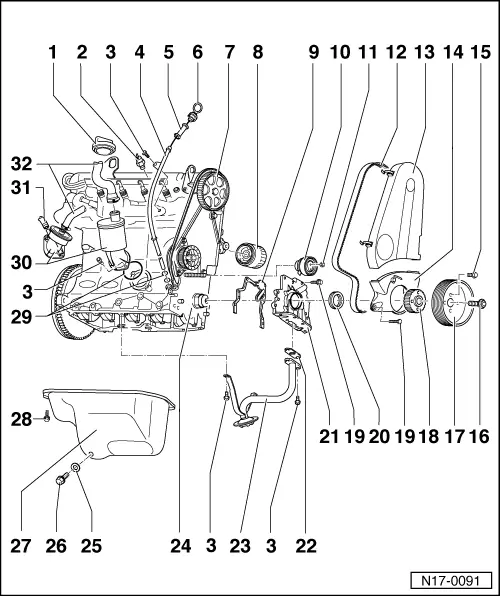

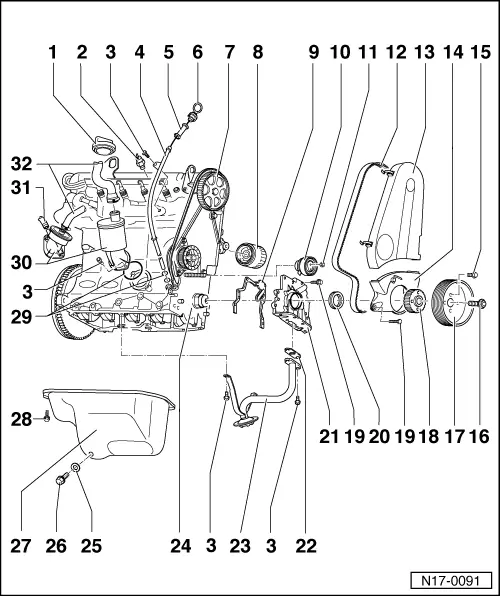

Golf Mk3

|

|

|

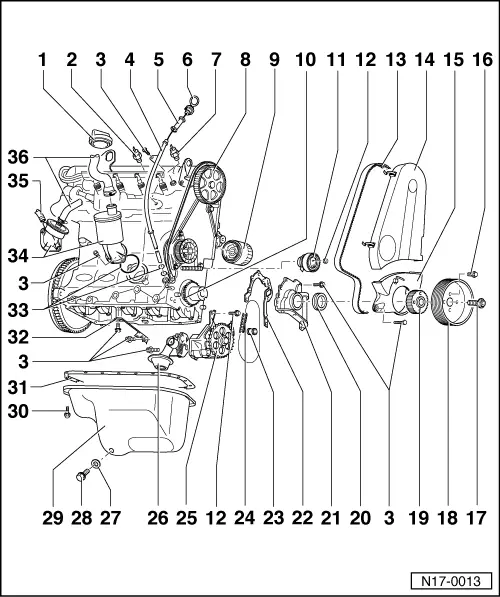

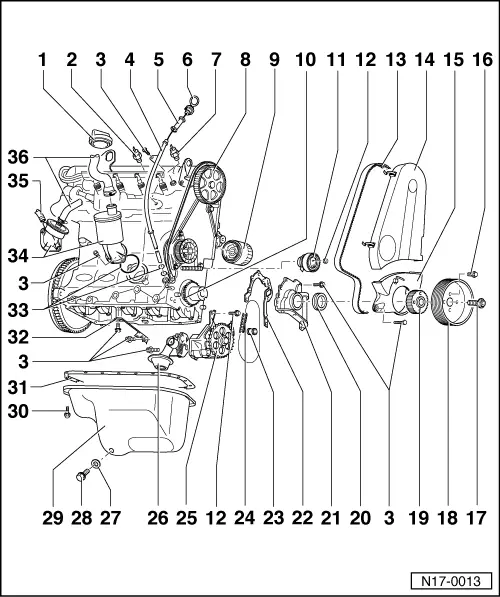

Vehicles with oil pump driven by chain

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

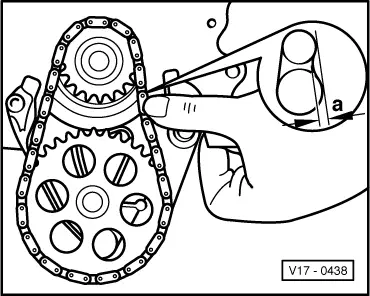

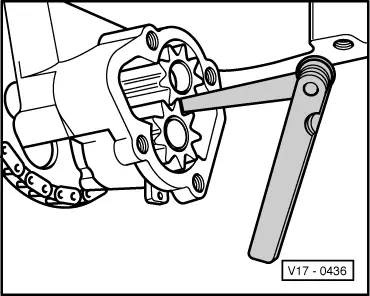

→ Fig. 1 Checking oil pump backlash New: 0.05 mm Wear limit: 0.20 mm |

|

|

|

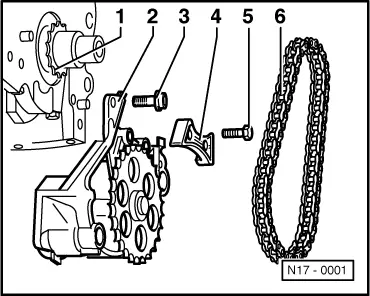

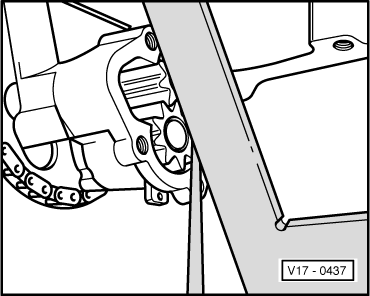

→ Fig. 2 Checking oil pump axial clearance Wear limit: 0.15 mm |

|

|

|

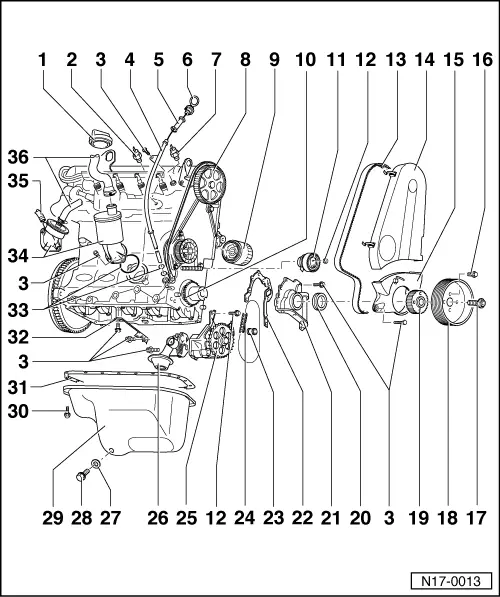

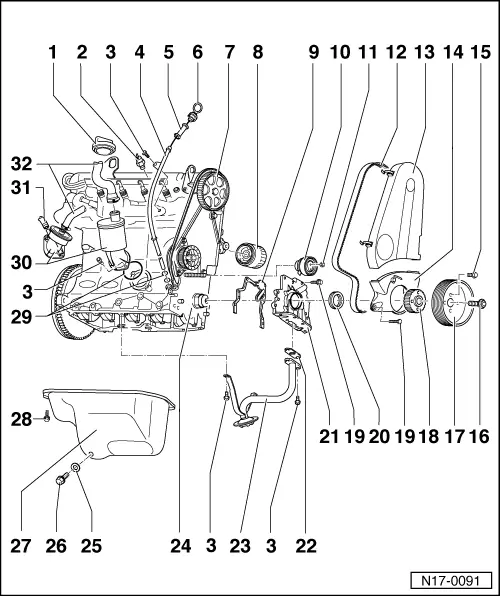

Vehicles with Duo-centric oil pump

|

|

|

|

|

|

|

|

|

|

|

|

|