Golf Mk3

|

|

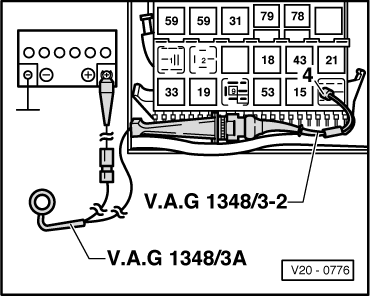

Note: If the relay cannot be removed from the relay plate without tools then first disconnect battery earth strap.

Fuel pump runs:

Engine codes ABD, ABU, AEX, APQ: => Current flow diagrams, Electrical fault finding and Fitting locations, Fuel supply system Engine code AEA: Engine code AEE: => 1AV Injection and ignition system; => Repair group 01; Self-diagnosis; Final control diagnosis Fuel pump does not run:

|

|

|

LED does not light up:

LED lights up (voltage supply OK.):

If not open circuit can be found:

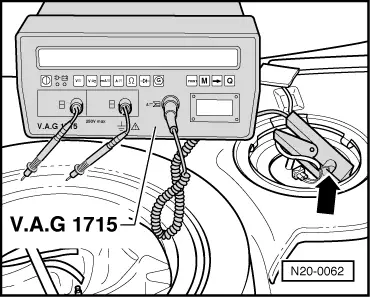

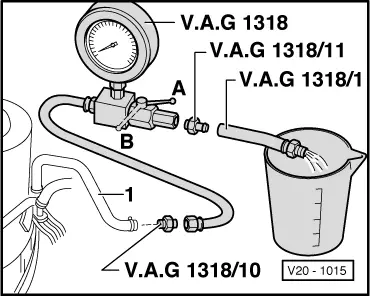

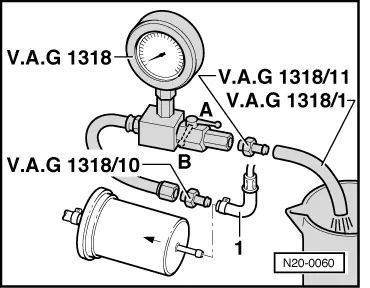

Checking delivery rate Test conditions

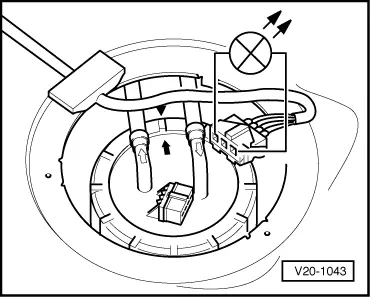

Test sequence

Warning!

Fuel supply lines are under pressure! Before removing from hose connection wrap a cloth around the connection. Then release pressure by carefully pulling hose off connection. |

|

|

|

|

|

|

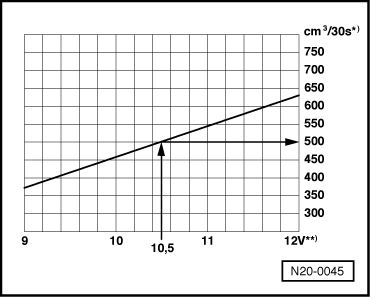

→ Engine code ABD, ABU, AEA *) Minimum delivery cm3/30 seconds **) Voltage at fuel pump with engine stopped and pump running (approx. 2 volts less than battery voltage). Example: During the test a voltage of 12.5 volts is measured at the battery. As the voltage at the pump is approx. 2 volts less than the battery voltage then this will equate to a minimum delivery of 500 cm3/30 s. |

|

|

|

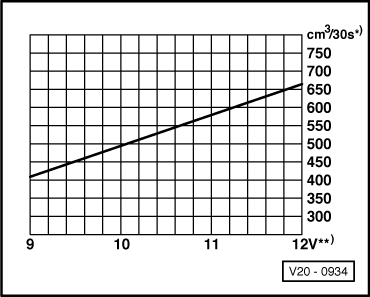

→ Engine code AEE, AEX, APQ *) Minimum delivery cm3/30 seconds **) Voltage at fuel pump with engine stopped and pump running (approx. 2 volts less than battery voltage). If the minimum delivery rate is not attained:

|

|

|

If the minimum delivery rate is now attained:

If the minimum delivery rate is again not attained:

Only when up to now no fault has been detected:

If the delivery rate has been attained but nevertheless you suspect a fuel supply system fault (e.g. intermittent failure of fuel supply system):

|