Golf Mk3

|

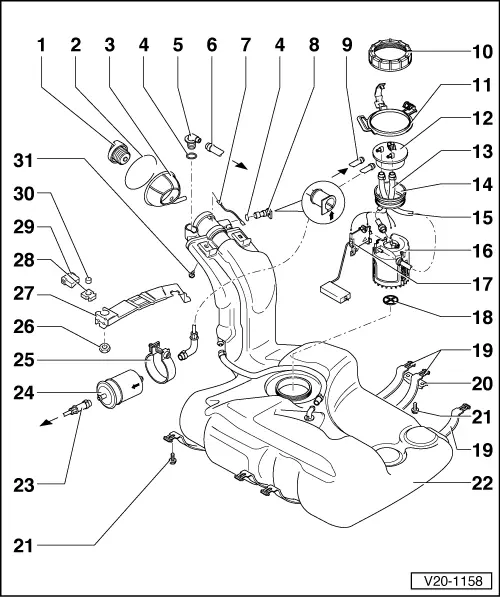

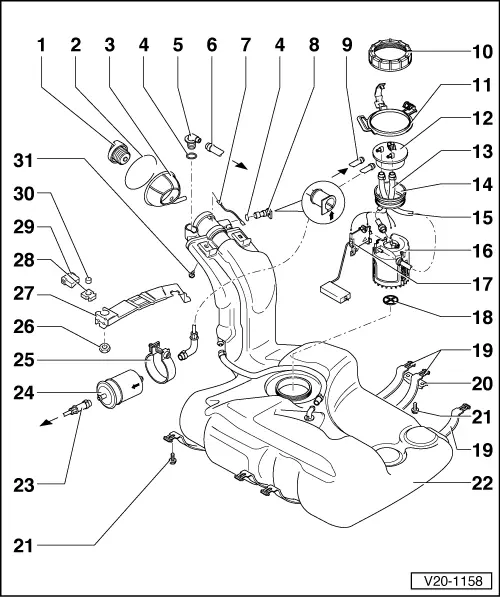

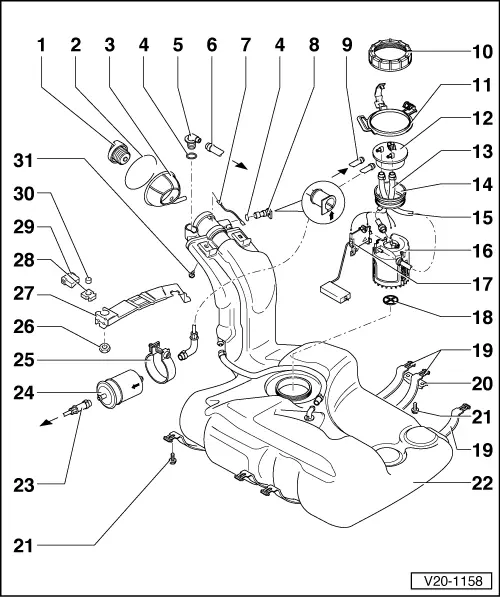

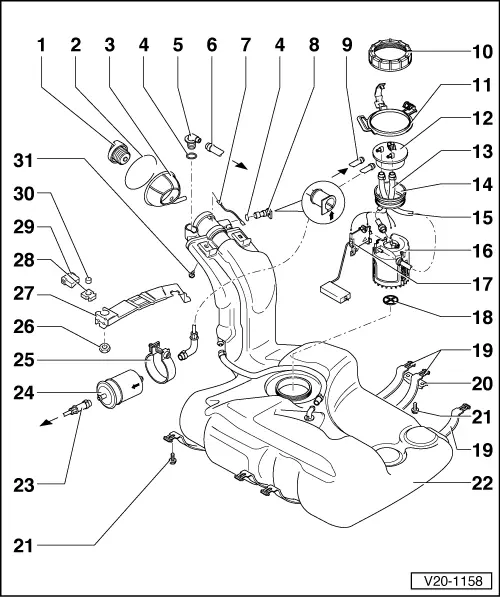

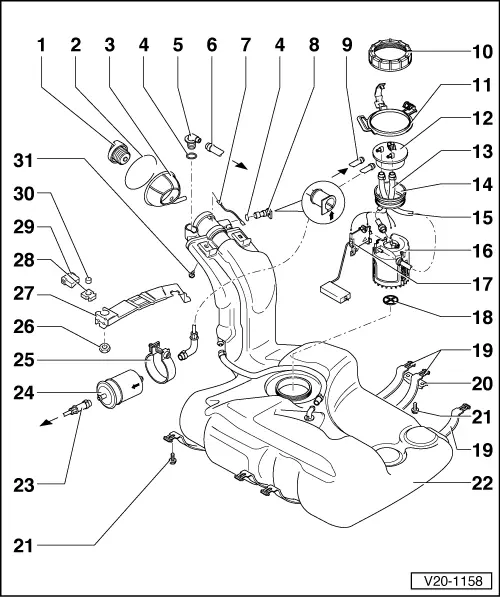

Removing and installing parts of fuel supply system

Removing and installing fuel tank with its attachments

|

|

|

|

Note: Please ensure after all repairs to the fuel supply unit and the fuel gauge sender, the corrugated hoses/hoses between delivery unit and fuel tank flange do not make contact with the fuel tank, otherwise pump noises will be transmitted. |

|

|

|

|

|

=> Repair group 24; Mixture preparation, injection

|

|

|

=> Current flow diagrams, Electrical fault finding and Fitting locations

|

|

|

|

|

|

|

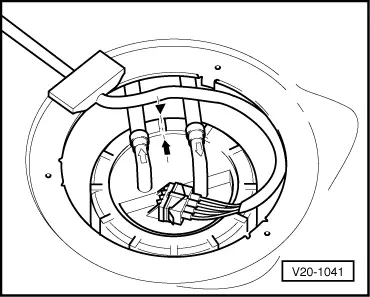

→ Fig. 1 Installation position of fuel delivery unit flange Marking on the flange must align with marking on the fuel tank. |

|

|

|

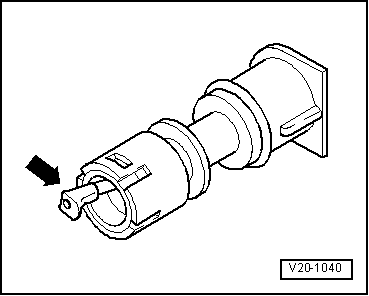

→ Fig. 2 Checking vent valve Lever in rest position: Closed Lever pushed in direction of arrow: Open |