Golf Mk3

|

Removing and installing parts of fuel supply system

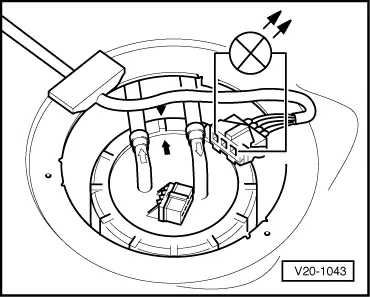

Checking fuel pump

|

|

|

|

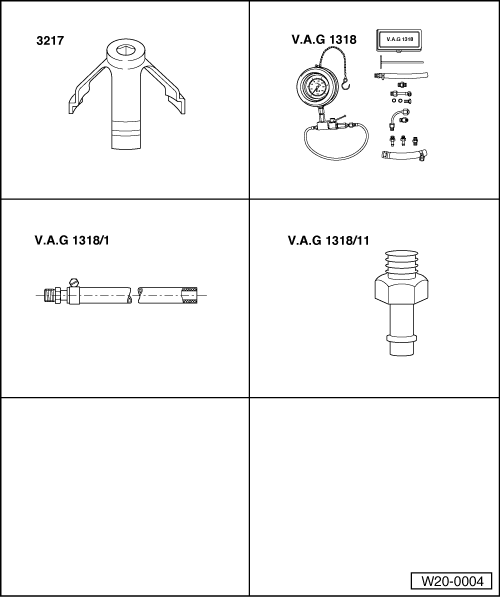

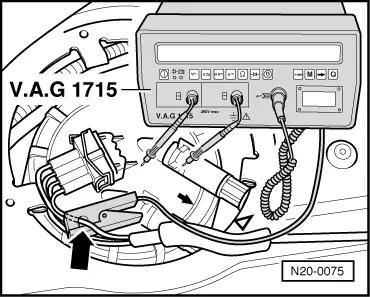

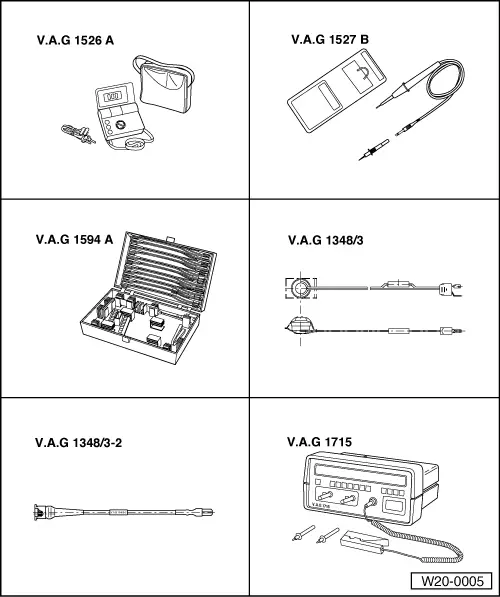

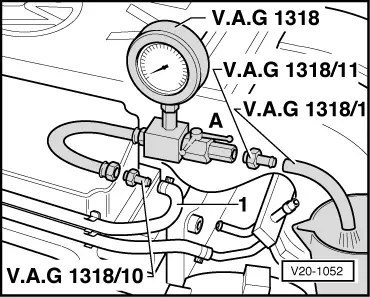

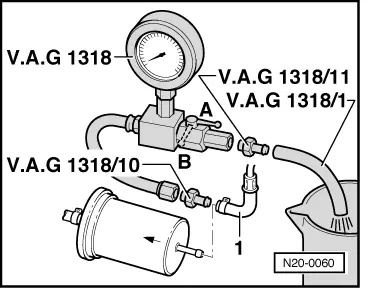

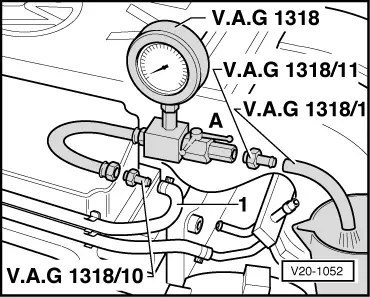

Special tools, workshop equipment, test and measuring appliances and auxiliary items required

|

|

|

|

Fuel pump must be heard to run briefly. If the fuel pump does not run:

Notes:

Fuel pump runs:

=> Current flow diagrams, Electrical fault finding and Fitting locations

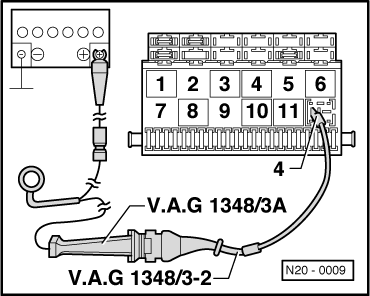

Fuel pump does not run:

|

|

|

LED does not light up:

=> Current flow diagrams, Electrical fault finding and Fitting locations binder LED lights up (voltage supply OK.):

If not open circuit can be found:

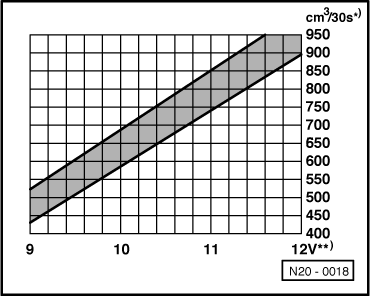

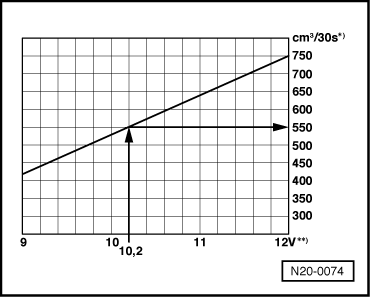

Checking delivery rate The specification for this test is dependent upon fuel pump pressure.

|

|

|

Note: To prevent fuel spray when loosening connections wrap a cloth around the connection.

Vehicles ▸07.95

|

|

|

*) Minimum delivery cm3/30 seconds **) Voltage at fuel pump with engine stopped and pump running (approx. 2 volts less than battery voltage). Vehicles 08.95 ▸

|

|

|

*) Minimum delivery cm3/30 seconds **) Voltage at fuel pump with engine stopped and pump running (approx. 2 volts less than battery voltage). Example: During the test a voltage of 12.2 volts is measured at the battery. As the voltage at the pump is approx. 2 volts less than the battery voltage then this will equate to a minimum delivery of 550 cm3/30 s. For all vehicles: If the minimum delivery rate is not attained:

|

|

|

If the minimum delivery rate is now attained:

If the minimum delivery rate is again not attained:

Only when up to now no fault has been detected:

If the delivery rate has been attained but nevertheless you suspect a fuel supply system fault (e.g. intermittent failure of fuel supply system):

|

|

|

Warning!

Danger of spray when opening the shut-offtap, hold container over the free connection of the pressure gauge.

|