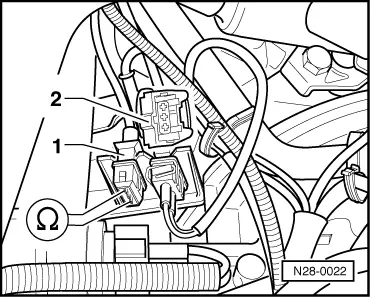

Checking Knock Sensor and Knock Control on Motronic Injection and Ignition System

| → Indicated on display: |

|

||

|

| → Indicated on display: |

|

||

|

| →

Indicated on display: (1...4 = Display zones) |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

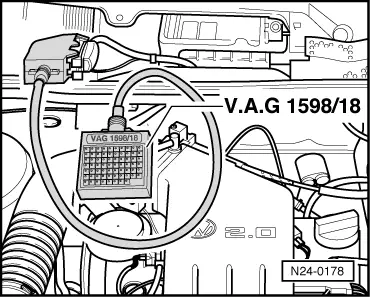

Note: The check must be carried out during a test drive as the knock control is not active until the engine is loaded for more than 3 ms.

Evaluating display group 45

Continuation | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

If the specification is attained: |

|

|

|

|

|

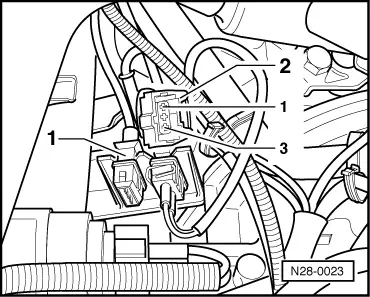

If no wiring fault is detected:

If the fault is still present (fault again in fault memory): |