Golf Mk4

|

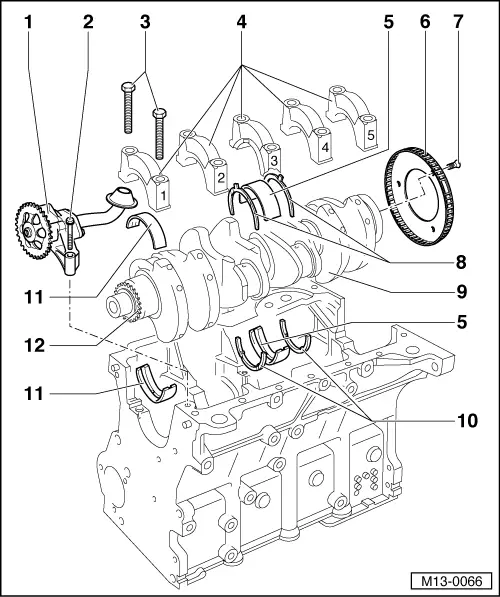

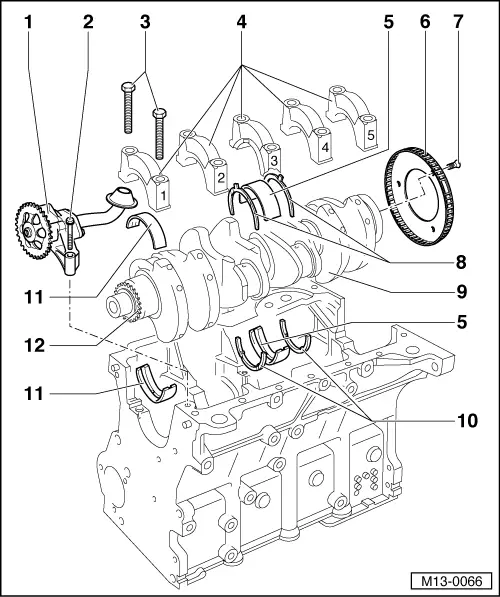

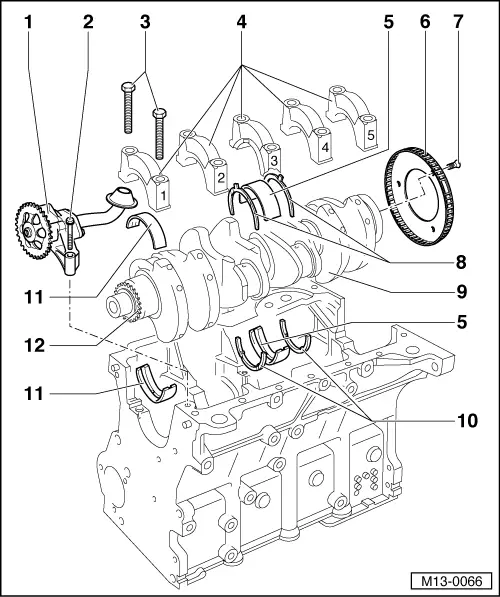

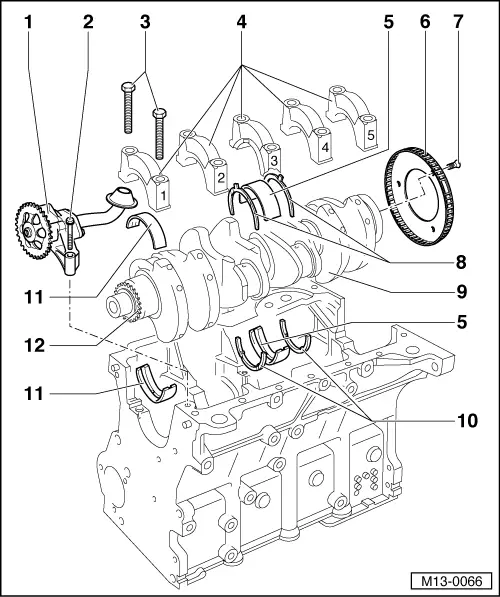

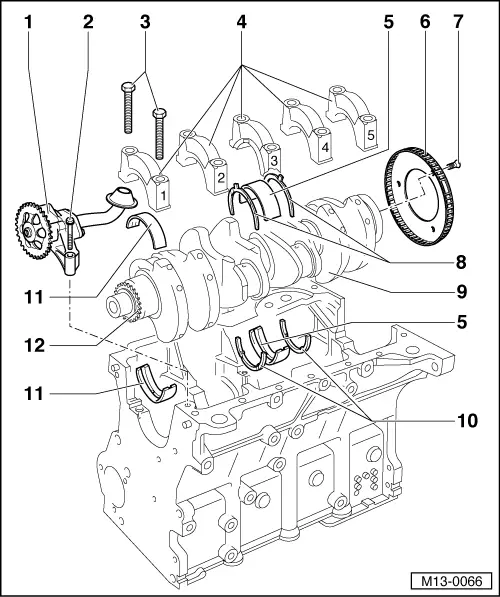

Removing and installing crankshaft

Removing and installing crankshaft

|

|

|

|

Notes:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

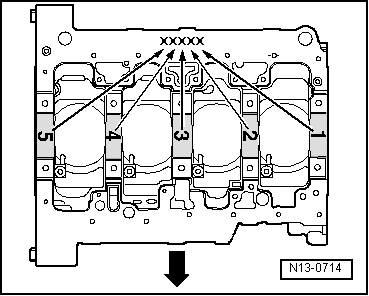

→ fig. 1 Upper crankshaft bearing identification (gradual introduction) In the factory the upper bearing caps are allocated with the correct thickness for the cylinder block. Coloured marks are used to identify the thickness of the bearing shells => Page 13-36. Which thickness of shell should be fitted to which location is marked by a letter on the lower sealing surface of the cylinder block -x-. Arrow indicates direction of travel (forwards). |