Golf Mk4

|

Removing and installing parts of fuel supply system

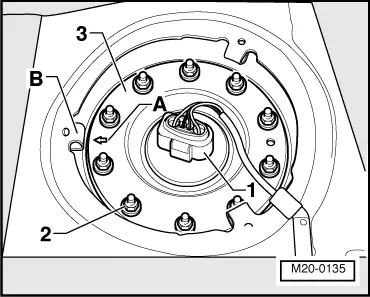

Removing and installing fuel delivery unit

|

|

|

|

Special tools, workshop equipment, testers, measuring instruments and auxiliary items required

Removing Prerequisites

Notes:

Warning:

Fuel supply lines are under pressure! When disconnecting the connectors wear eye protection and fuel-resistant gloves. Release pressure by carefully pulling connector off connection.

|

|

|

|

|

|

|

|

|

|

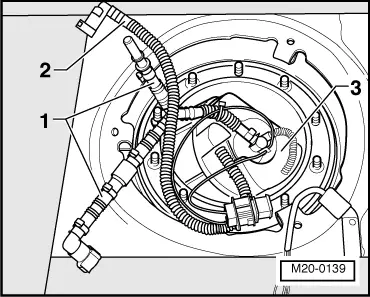

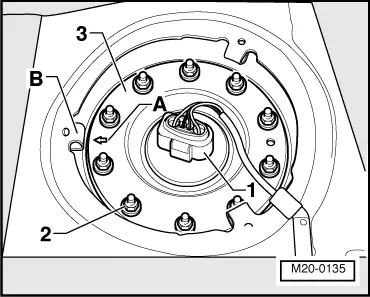

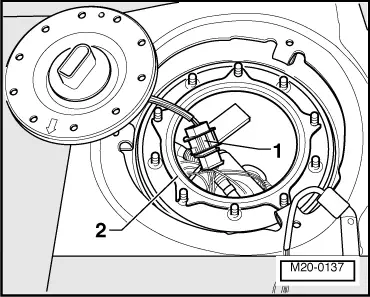

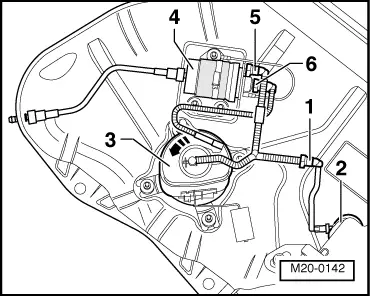

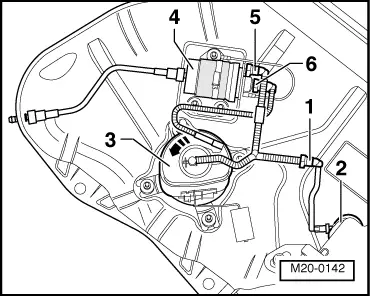

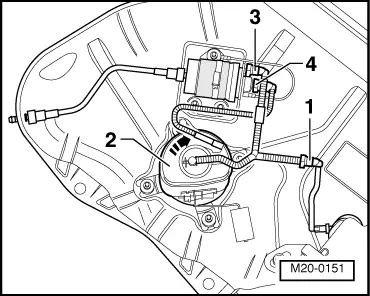

→ Note: For ease of illustration, the fuel tank upper shell is not shown. The components are shown simplified.

|

|

|

Note: Observe that the strainer filter and the fuel gauge sender are not damaged.

|

|

|

|

Installation of the fuel delivery unit is performed in reverse order. When doing this note the following:

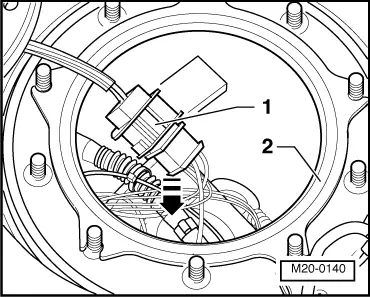

Note: The supply and return hose connectors must audibly engage. Check for correct seat by tightening.

|

|

|

Note: The working area of the float must not be reduced. |

|

|

|