Note | Refer to procedure „Removing gearbox“ for required special tools → Chapter. |

| –

| All threaded holes into which self-locking bolts are to be screwed must be cleaned of residual locking fluid with a thread chaser. |

| –

| Always renew self-locking bolts and nuts. |

| –

| Clean input shaft splines and lightly grease with grease -G 000 100-. |

| The clutch plate must slide easily to and fro on the input shaft. |

| –

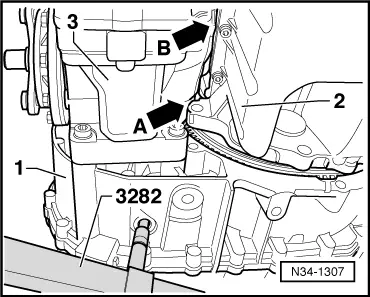

| Check whether dowel sleeves for aligning engine and gearbox are fitted in cylinder block and install if necessary. |

| If dowel sleeves are not fitted, difficulties shifting gears, clutch problems and possible noises from the gearbox (rattling of gears which are not engaged) could occur. |

| –

| Ensure that intermediate plate is correctly seated on engine. |

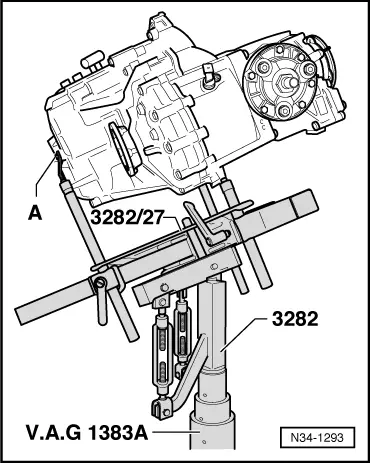

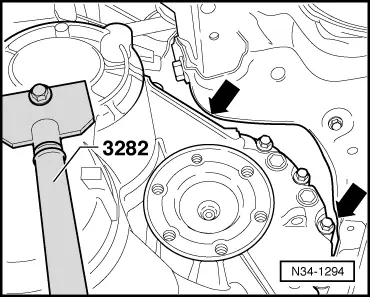

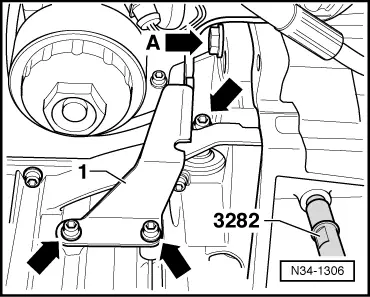

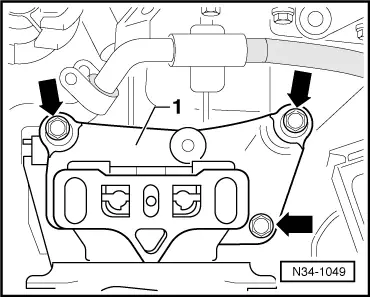

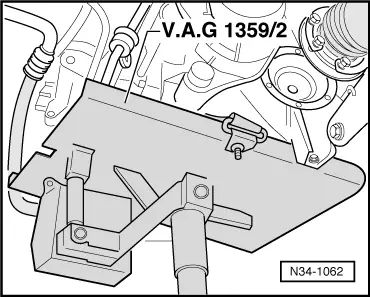

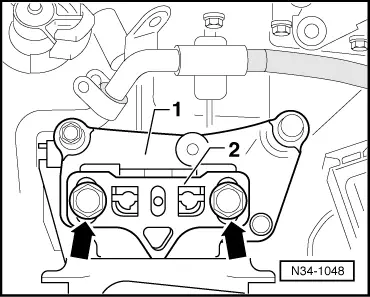

| To install gearbox „02M/02Y“, set up gearbox support -3282- with adjustment plate -3282/27-. |

| –

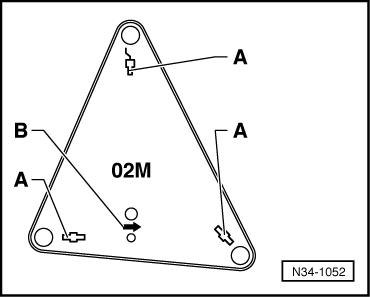

| Align arms of gearbox support according to holes in adjustment plate. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note Note

Note

Note

Note

Note

Note

WARNING

WARNING