Golf Mk4

| Dismantling and assembling output shaft for 1st through 4th gears |

| Special tools and workshop equipment required |

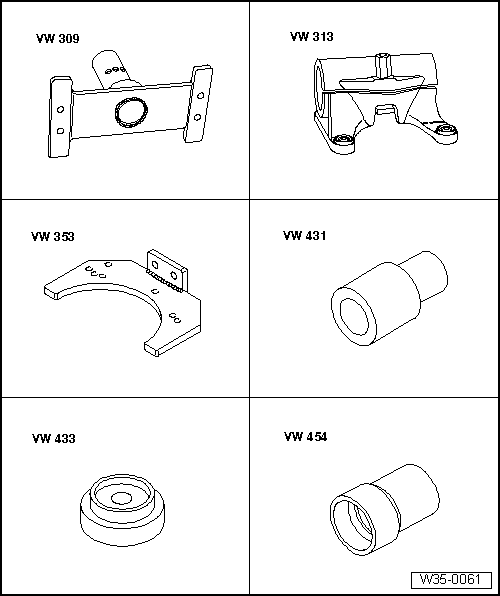

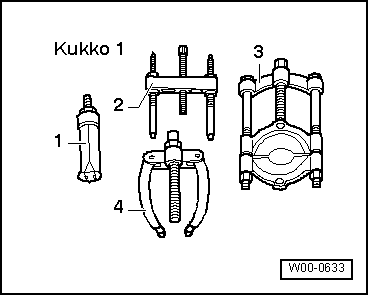

| t | Pressure plate -VW 401- |

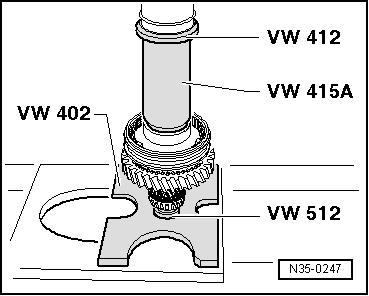

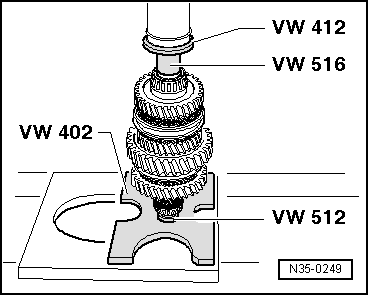

| t | Pressure plate -VW 402- |

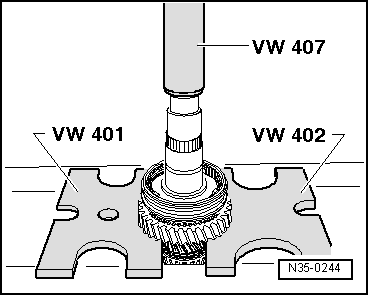

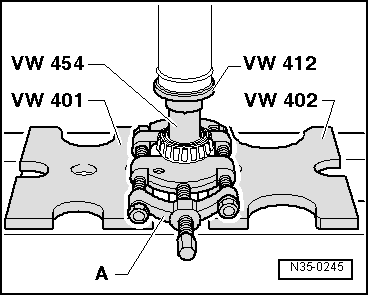

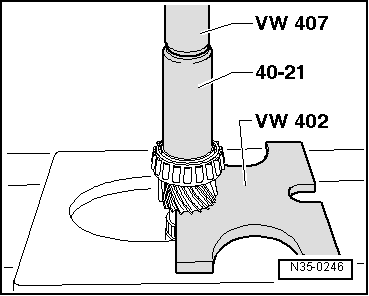

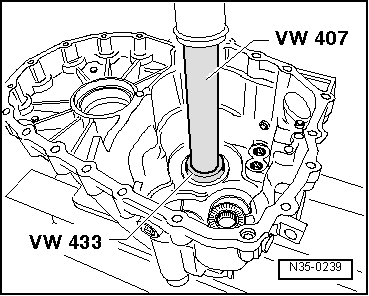

| t | Press tool -VW 407- |

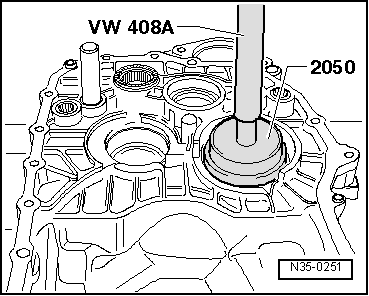

| t | Press tool -VW 408 A- |

| t | Press tool -VW 412- |

| t | Tube -VW 415 A- |

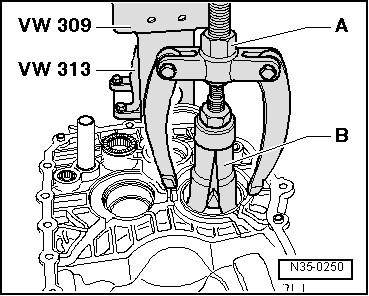

| t | Support plate -VW 309- |

| t | Support clamp -VW 313- |

| t | Gearbox support -VW 353- |

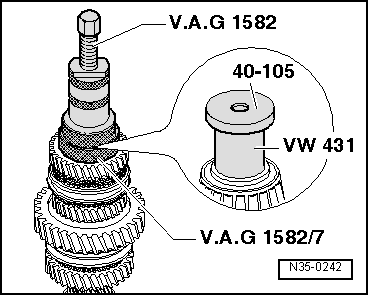

| t | Thrust piece -VW 431- |

| t | Thrust piece -VW 433- |

| t | Thrust piece -VW 454- |

| t | Thrust pad -VW 512- |

| t | Tube -VW 516- |

| t | Tube -VW 519- |

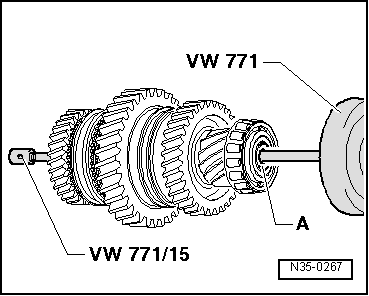

| t | Multipurpose tool -VW 771- |

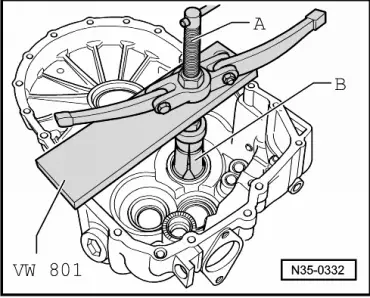

| t | Support plate -VW 801- |

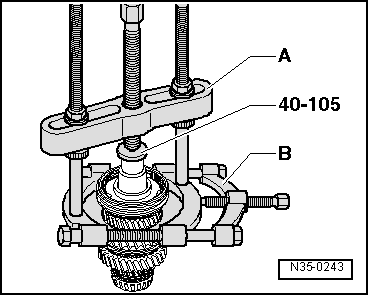

| t | Thrust plate -40-105- |

| t | Drift sleeve -40-20- |

| t | Drift sleeve -40-21- |

| t | Thrust piece -2050- |

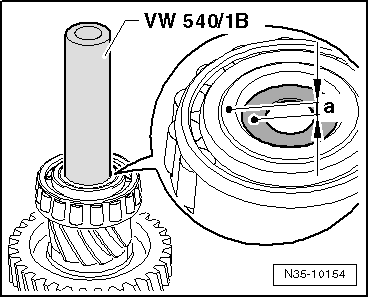

| t | Supplementary set for engine and gearbox support -VW 540/1 B- |

| t | Tapered roller bearing puller -V.A.G 1582- |

| t | Adapter -V.A.G 1582/7- |

|

|

Note

Note

|

|

| 1 - | Clutch housing |

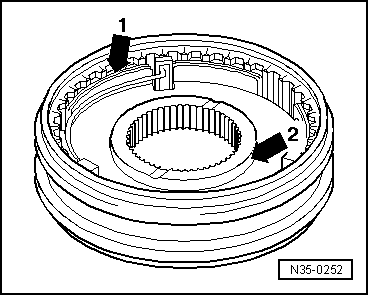

| 2 - | Oil deflector ring |

| 3 - | Dished washer |

| q | Pulling out → Fig. |

| q | Pressing in → Fig. |

| 4 - | Tapered roller bearing outer race |

| q | Pulling out → Fig. |

| q | Pressing in → Fig. |

| 5 - | Tapered roller bearing inner race |

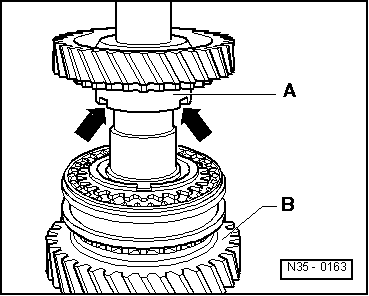

| q | Pressing off → Fig. |

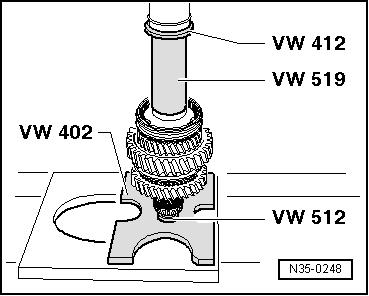

| q | Pressing on → Fig. |

| 6 - | Output shaft |

| q | For 1st through 4th gears |

| q | Adjusting → Chapter |

| 7 - | Needle bearing |

| q | For 2nd gear |

| 8 - | Synchromeshed gear for 2nd gear |

| 9 - | Synchro-ring |

| q | (Inner ring for 2nd gear) |

| q | Check for wear → Fig. |

| q | Check lugs for scoring |

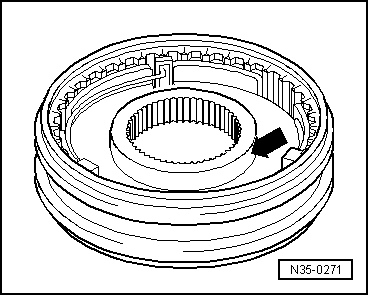

| q | Installation position → Fig. |

| 10 - | Outer ring for 2nd gear |

| q | Place on synchro-ring → Item |

| q | Renew if scored |

| q | Installation position → Fig. |

| 11 - | Synchro-ring for 2nd gear |

| q | Check for wear → Fig. |

| q | Installation position → Fig. |

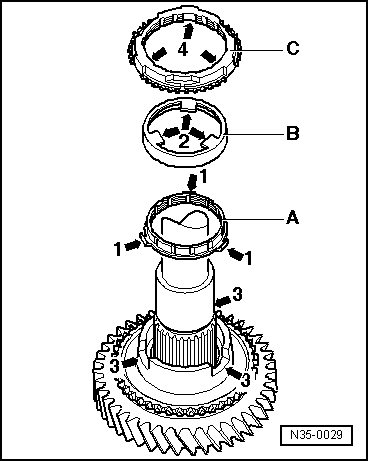

| 12 - | Locking collar with synchro-hub for 1st and 2nd gears |

| q | After removing retaining ring → Item, press off with synchromeshed gear for 2nd gear → Fig. |

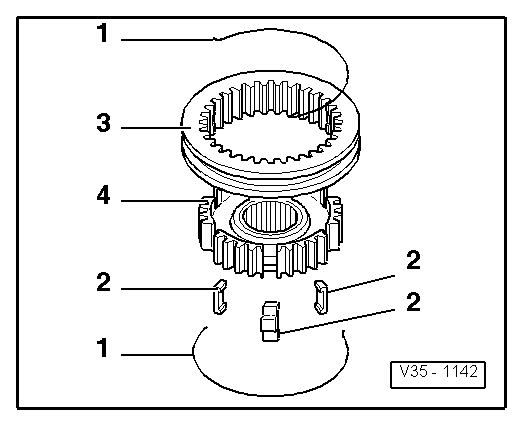

| q | Dismantling → Fig. |

| q | Assembling locking collar and synchro-hub → Fig. |

| q | Installation position → Fig. |

| q | Pressing on → Fig. |

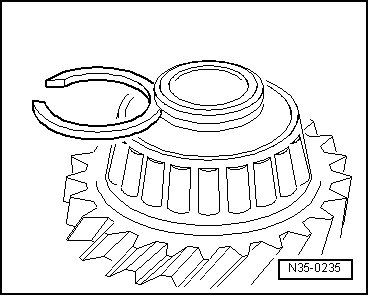

| 13 - | Retaining ring |

| 14 - | Synchro-ring for 1st gear |

| q | Check for wear → Fig. |

| q | Assemble so that notches engage in locking pieces of locking collar → Item |

| 15 - | Outer ring for 1st gear |

| q | Insert in synchro-ring → Item; installation position → Fig. |

| q | Renew if scored |

| 16 - | Synchro-ring |

| q | (Inner ring for 1st gear) |

| q | Check for wear → Fig. |

| q | Check lugs for scoring |

| q | Installation position → Fig. |

| 17 - | Needle bearing |

| q | For 1st gear |

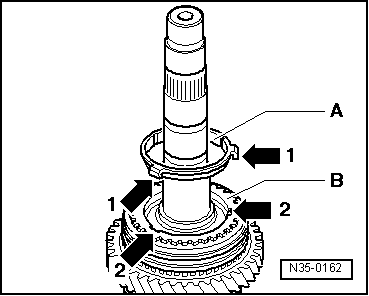

| 18 - | Synchromeshed gear for 1st gear |

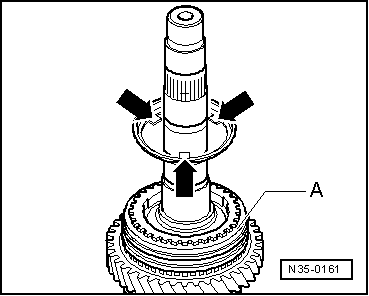

| q | Installation position → Fig. |

| 19 - | Thrust washer |

| q | For 1st through 4th gears |

| q | Insert lugs on thrust washer in hole of output shaft. |

| 20 - | Washer |

| q | Holds thrust washers → Item on output shaft. |

| 21 - | Needle bearing |

| q | For 4th gear |

| 22 - | Synchromeshed gear for 4th gear |

| 23 - | Synchro-ring for 4th gear |

| q | Check for wear → Fig. |

| 24 - | Locking collar with synchro-hub for 3rd and 4th gears |

| q | After removing retaining ring → Item, pull off via 4th gear synchromeshed gear → Item. |

| q | Dismantling → Fig. |

| q | Installation position, locking collar and synchro-hub → Fig. |

| q | Assembling locking collar and synchro-hub → Fig. and → Fig. |

| q | Pressing on → Fig. |

| 25 - | Retaining ring |

| 26 - | Synchro-ring for 3rd gear |

| q | Check for wear → Fig. |

| 27 - | Outer ring for 3rd gear |

| q | Insert in synchro-ring → Item; installation position → Fig. |

| q | Renew if scored |

| 28 - | Synchro-ring |

| q | (Inner ring for 3rd gear) |

| q | Check for wear → Fig. |

| q | Check lugs for scoring |

| q | Installation position → Fig. |

| 29 - | Needle bearing |

| q | For 3rd gear |

| 30 - | Synchromeshed gear for 3rd gear |

| q | Installation position → Fig. |

| 31 - | Tapered roller bearing inner race |

| q | Pulling off → Fig. |

| q | Pressing on → Fig. |

| 32 - | Retaining ring |

| q | If tapered roller bearing → Item and output shaft → Item are renewed, redetermine → Fig. |

| 33 - | Tapered roller bearing outer race |

| q | Pulling out → Fig. |

| q | Pressing in → Fig. |

| 34 - | Shim |

| q | Determining thickness → Chapter |

| 35 - | Gearbox housing |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

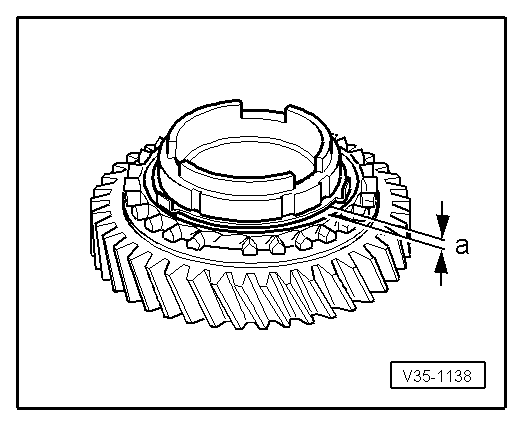

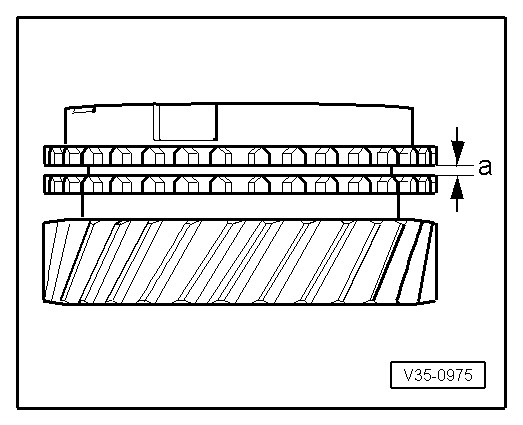

| Gap „a“ | Installation dimension | Wear limit |

| 1st, 2nd and 3rd gears | 0.75 ... 1.25 mm | 0.3 mm |

|

|

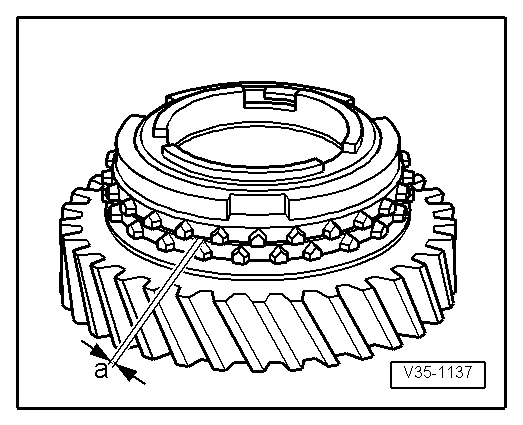

| Gap -a- | Installation dimension | Wear limit |

| 1st, 2nd and 3rd gears | 1.2 ... 1.8 mm | 0.5 mm |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

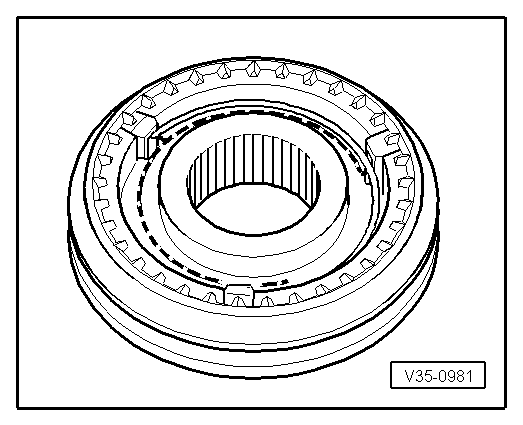

| Gap -a- | Installation dimension | Wear limit |

| 4th gear | 1.0 ... 1.7 mm | 0.5 mm |

|

|

|

|

| Thickness (mm) | ||

| 1.79 | 1.89 | 1.98 |

| 1.83 | 1.92 | |

| 1.86 | 1.95 | |

|

|

|

|