Golf Mk4

| Removing and installing camshaft |

| Special tools and workshop equipment required |

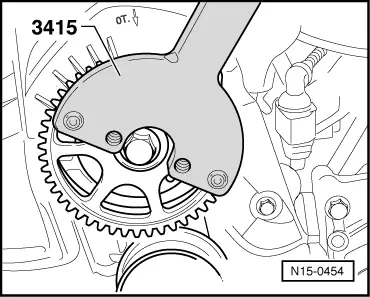

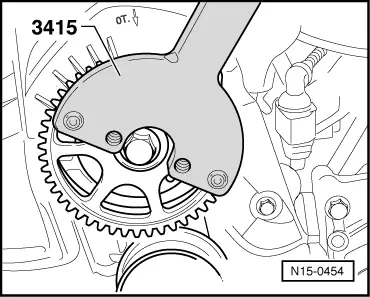

| t | Counterhold tool -3415- |

| t | Torque wrench -V.A.G 1331- |

| t | Torque wrench -V.A.G 1332- |

| t | Sealant -AMV 174 004 01- |

Note

Note

|

|

|

Note

Note

|

|

|

|

Note

Note

Note

Note

|

|