| Indicated on display: (1…4 = display zones) |

| The display in display zone 2 must fluctuate every 10 secs. between EGR active and EGRn.active. |

| The displays in display zone 3 and 4 must fluctuate within the following control range: |

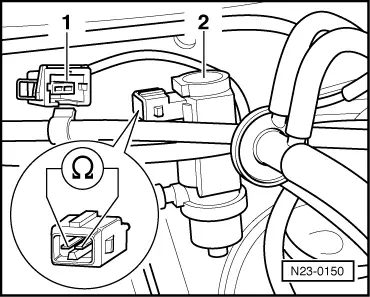

Note | If a constant 550 mg/H is displayed in display zone 3; check air mass meter: → Rep. Gr.23 |

| –

| Specification display zone 3: 400…580 mg/H |

| –

| Specification display zone 4 0…5 % |

| –

| Specification display zone 3150…340 mg/H |

| –

| Specification display zone 4 95…100 % |

Note | Displays in display zone 3 depend on pressure and therefore altitude. The values displayed are in relation to 0 m (sea level). If the values displayed deviate greatly due to the altitude, check in display zone 3 if a specified difference of min. 100 mg/H is achieved between displays for EGR active and EGRn.active. |

| If the specifications are not obtained: |

| –

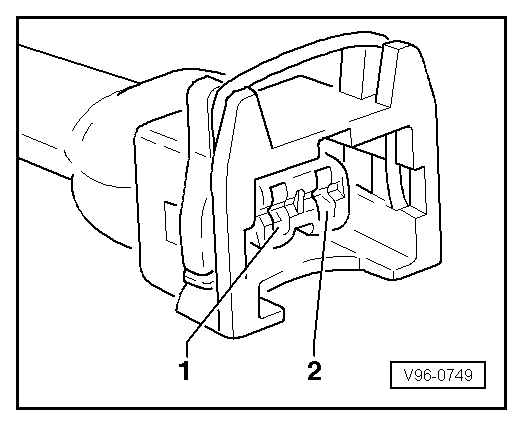

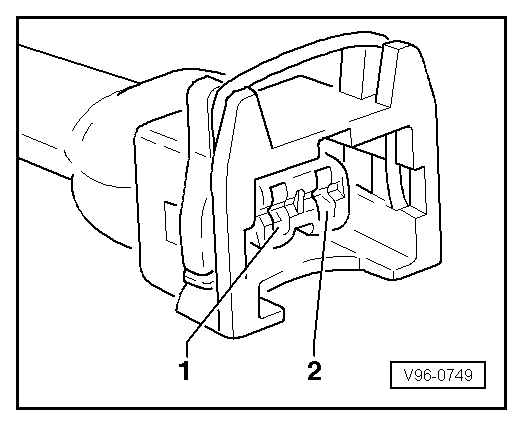

| Check mechanical exhaust gas recirculation valve → Chapter. |

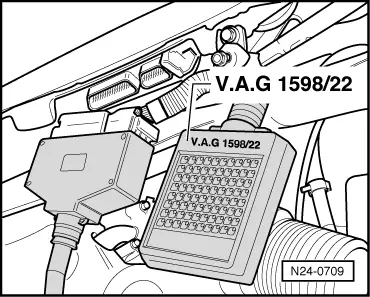

| Engine codes AGP (with 121-pin control unit), AQM |

|

|

System in basic setting 3 -> | 900 rpm EGRn.active 500 mg/H 0% |

|

Note

Note Note

Note Note

Note