| –

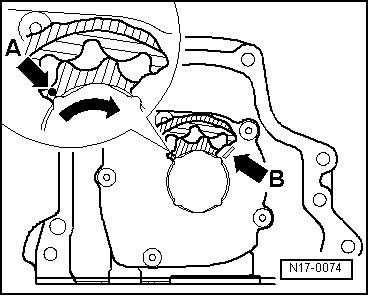

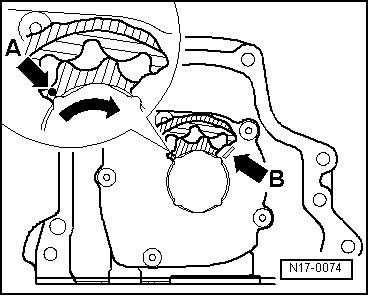

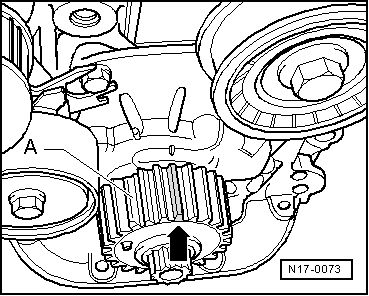

| Align one of the two markings -arrow A- of the oil pump inner rotor with installation position marking -arrow B- on oil pump housing cover. |

| –

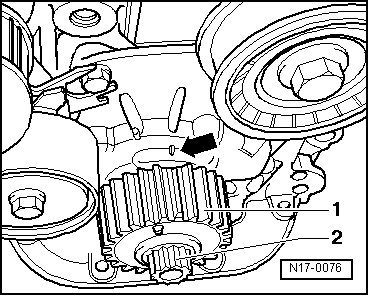

| Coat the four crankshaft follower polygon cams with oil. |

| –

| Lightly oil sealing lip of oil pump oil seal. |

| –

| Guide oil pump carefully onto crankshaft follower polygon cams. |

| –

| Align inner rotor to crankshaft follower polygon cams by turning slightly if necessary. |

| –

| Then slide oil pump carefully onto dowel sleeves. |

| –

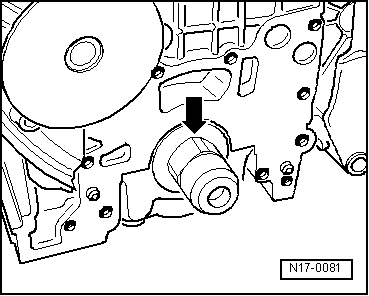

| Secure oil pump with new bolts. Specified torque: 12 Nm |

| –

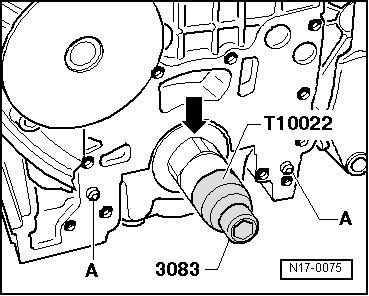

| Remove assembly tool -T10022-. |

| –

| Install suction line → Item. |

| –

| Install main drive tensioning roller, fit and tension toothed belt → Chapter. |

|

|

|

Note

Note

Note

Note