| –

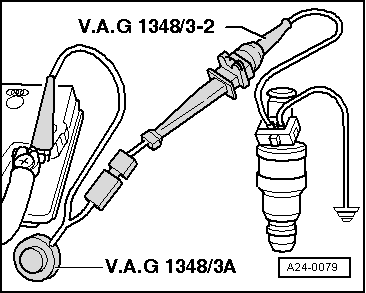

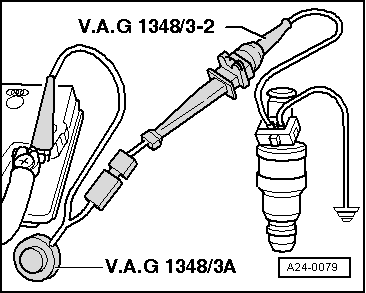

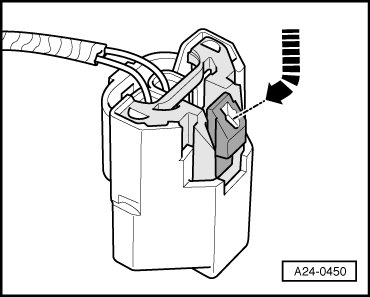

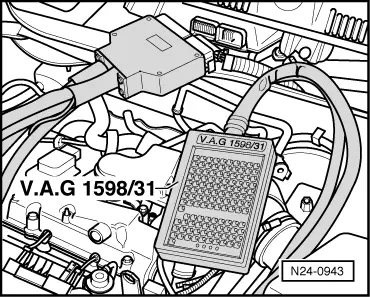

| Connect a contact of injector to be tested to engine earth using auxiliary cables from auxiliary measuring set -V.A.G 1594C-. |

| –

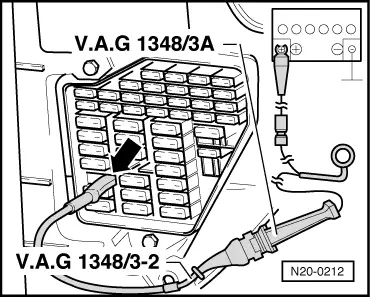

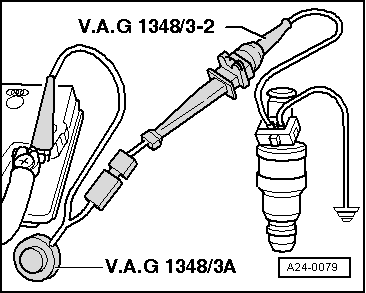

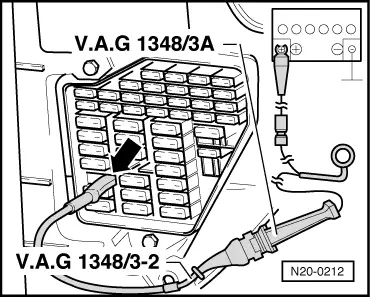

| Connect second injector contact with auxiliary cable to remote control for V.A.G 1348 -V.A.G 1348/3A- using adapter cable -V.A.G 1348/3-2-. |

| –

| Connect crocodile clip to battery (+). |

| –

| Operate remote control for V.A.G 1348 -V.A.G 1348/3A- for 30 seconds. |

| –

| Repeat check on other injectors. Use new measuring beakers. |

| –

| After all injectors have been activated, place measuring beakers on level surface and compare volume injected. Specification for: |

| AQP, AUE and BDE: 110-130 ml per valve |

| BFH, BJS and BML: 128-140 ml per valve |

| If the measured values of one or more injectors are above or below the prescribed specifications: |

| –

| Renew defective injector. |

| Pay attention to the following when installing the injectors: |

| t

| Renew O-rings on all injectors and lightly moisten with clean engine oil. |

| t

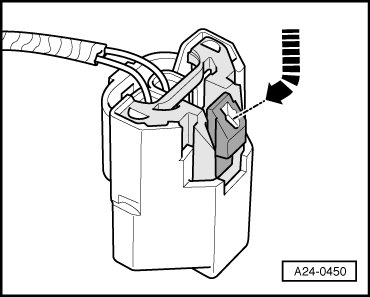

| Insert injectors vertically and in the correct position into the fuel rail and secure with retaining clips. |

| t

| Locate fuel rail with injectors installed and secured on lower part of intake manifold and press in evenly. |

|

|

|

Note

Note

Note

Note