| –

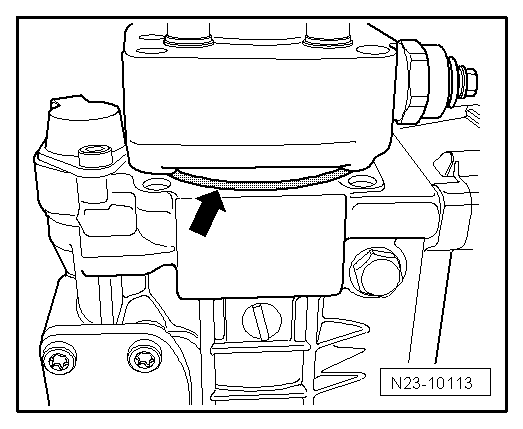

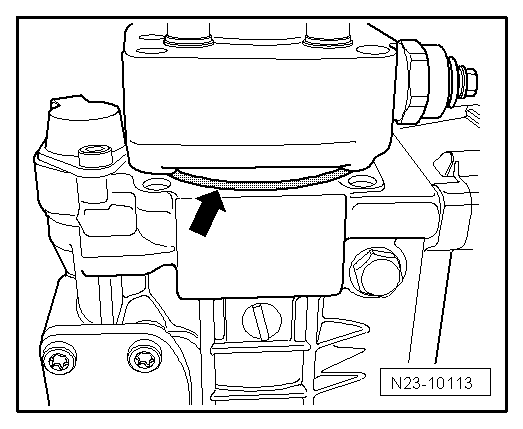

| Remove visible, old seal -arrow- by carefully pulling from seat and opening using a suitable tool. Do not scratch sealing surface. |

| –

| First position new seal behind fuel shut-off valve -N109- , then pull carefully over distributor head and allow to roll into groove. |

Caution | Subsequent tightening of distributor head securing bolts must be carried out in small steps under all circumstances, as distributor head may otherwise tilt within injection pump. In this case, the renewed seal is immediately damaged and leaking again! |

|

| –

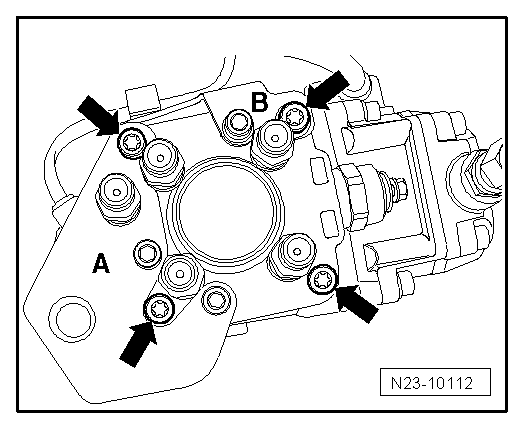

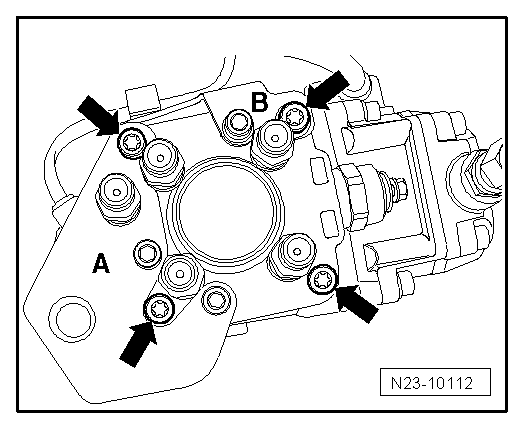

| Position securing bolts and carefully and diagonally bolt distributor head back into position in very small steps. |

| –

| Tighten securing bolts to 12 Nm. |

| –

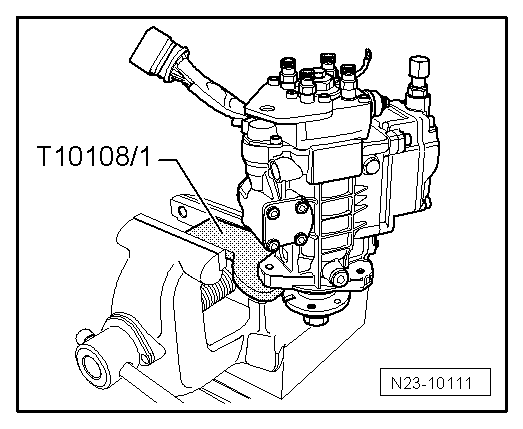

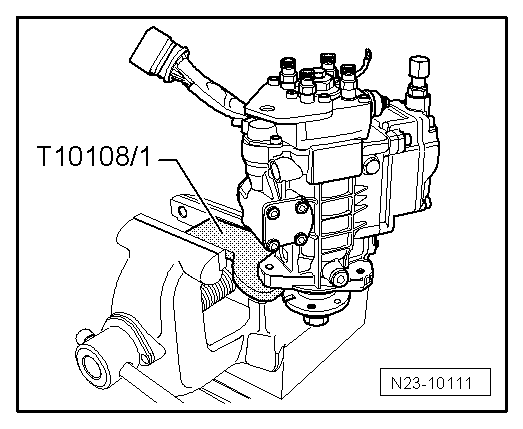

| Bolt retaining plate and cable of fuel shut-off valve -N109- back on. |

| –

| Install injection pump → Chapter and fill via return line using diesel extractor -VAS 5226-. |

|

|

|