| t

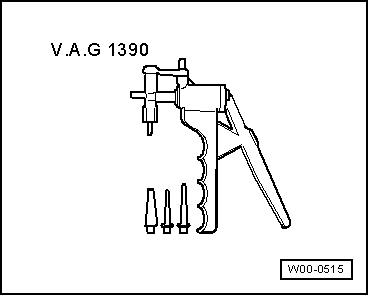

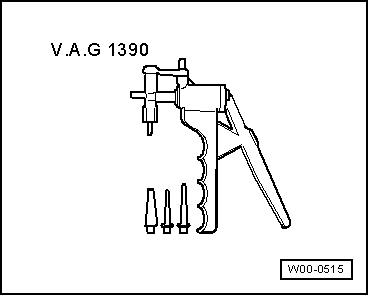

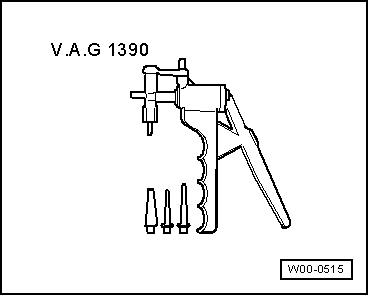

| Hand vacuum pump with accessories -V.A.G 1390/- |

| t

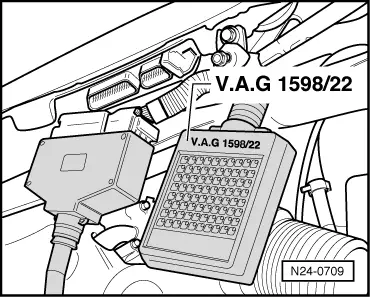

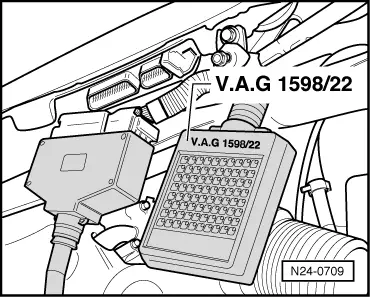

| Adapter -V.A.G 1598/22- |

| t

| Hand multimeter -V.A.G 1526C- or multimeter -V.A.G 1715- |

| t

| Adapter set -V.A.G 1594C- |

| –

| Start engine and run at idling speed. |

| –

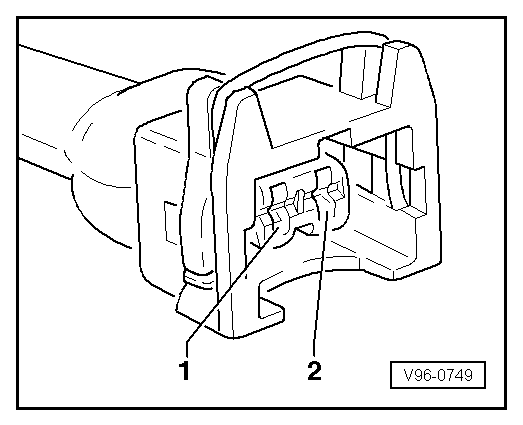

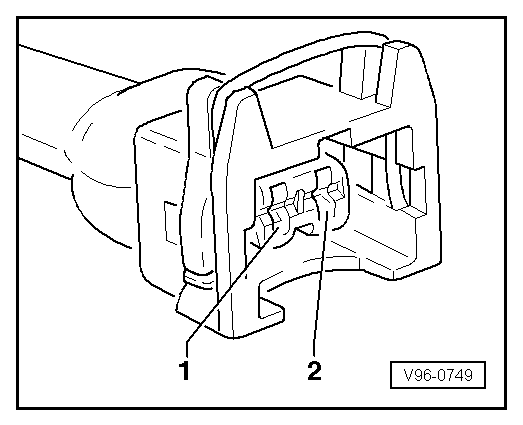

| Observe positioning lever on intake manifold flap (2nd person required). |

| –

| The intake manifold flap must, after switching off ignition, close and after approx. 3 seconds open again. |

| If change-over does not occur, the following checks must be carried out. |

| –

| Check intake manifold flap change-over mechanics for freedom of movement. To do this, operate rods by hand. |

| –

| Check function of vacuum actuator using hand vacuum pump with accessories -V.A.G 1390/-. |

| –

| Check that vacuum lines are connected correctly. |

| If no fault is found in the mechanical components: |

| –

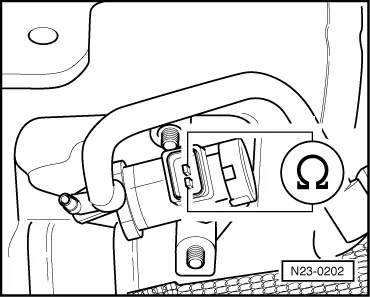

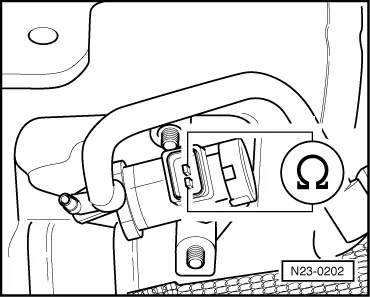

| Check variable intake manifold flap change-over valve -N239-. |

| –

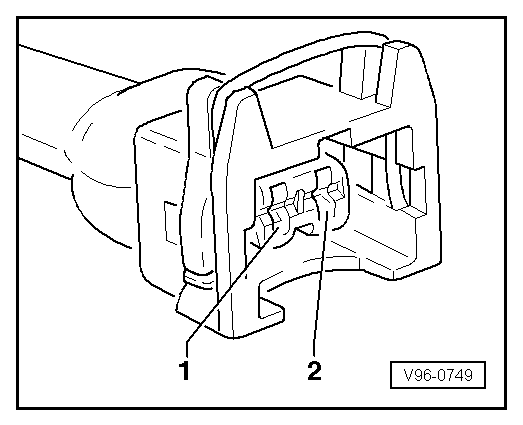

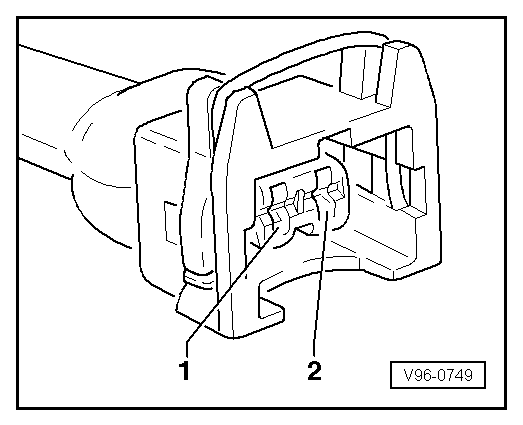

| Pull connector off variable intake manifold flap change-over valve -N239-. |

|

|

|