Golf Mk4

|

|

|

Test conditions

Notes:

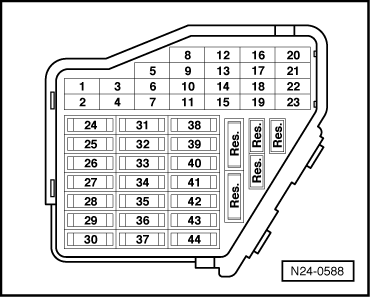

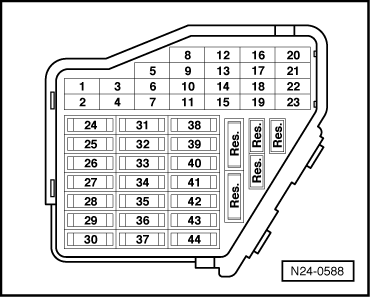

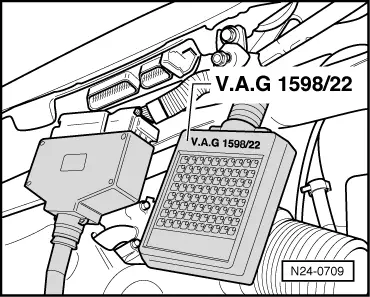

Checking voltage supply |

|

|

If no voltage is present:

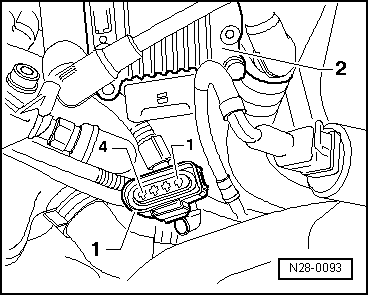

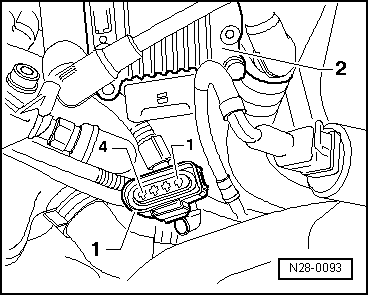

Checking activation Warning!

During the following test do not touch the connections to the ignition coils or test cables. |

|

|

|

|

|

If the LED flickers and there is voltage between contacts 2 + 4:

|

|

|

|

The LED does not flicker:

|

|

|

If no wiring fault is detected and voltage was present between contacts 2+4:

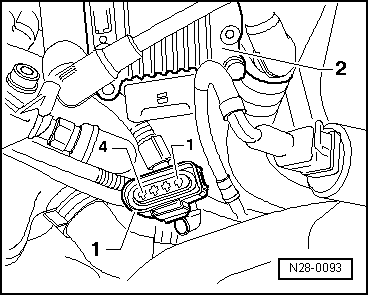

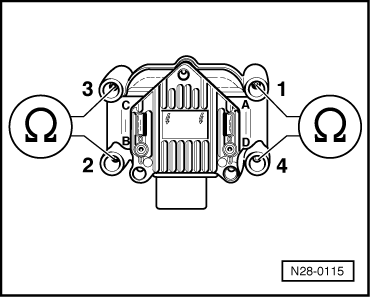

Checking secondary resistance |

|

|

If the specifications are not attained: |