Golf Mk4

| IV - Repairing front drive shaft with triple roller joint AAR 2900 |

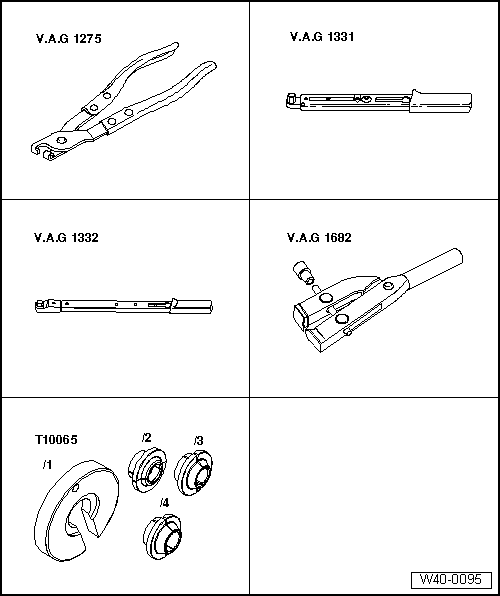

| Special tools and workshop equipment required |

| t | Thrust plate -VW 401- |

| t | Thrust plate -VW 402- |

| t | Press tool -VW 408 A- |

| t | Press tool -VW 411- |

| t | Tube -VW 416 B- |

| t | Thrust plate -VW 447 H- |

| t | Pliers -V.A.G 1275- |

| t | Torque wrench -V.A.G 1331- |

| t | Torque wrench -V.A.G 1332- |

| t | Pliers -V.A.G 1682- |

| t | Assembly tool -T10065- |

|

| Grease | of which in: | ||

| Outer joint | Total quantity | Joint | Boot |

| Ø mm | [g] | [g] | [g] |

| 90 | 100 | 50 | 50 |

| Inner joint | |||

| Ø mm | |||

| 124 | 140 | 70 | 70 |

|

| 1 - | Self-locking 12-point nut |

| q | Tightening → Chapter. |

| q | Remove any corrosion on thread of outer joint before fitting nut. |

| q | Renew each time after removing. |

| 2 - | Outer constant velocity joint |

| q | Renew only complete. |

| q | Removing → Fig.. |

| q | Installing: drive onto shaft with plastic hammer until compressed retaining ring seats. |

| q | Checking → Chapter. |

| q | Greasing → . |

| 3 - | Retaining ring |

| q | Renew each time after removing. |

| q | Insert in groove in shaft. |

| 4 - | Thrust washer |

| q | Installation position → Fig.. |

| 5 - | Dished spring |

| q | Installation position → Fig.. |

| 6 - | Clamp |

| q | Renew each time after removing. |

| q | Tighten with pliers -V.A.G 1682- → Fig.. |

| 7 - | Constant velocity joint boot |

| q | Check for splits and chafing. |

| q | Material: Hytrel (polyester elastomer). |

| 8 - | Clamp |

| q | Renew each time after removing. |

| q | Tightening → Fig.. |

| 9 - | Drive shaft |

| 10 - | Clamp |

| q | Renew each time after removing. |

| q | Tightening → Anchor. |

| 11 - | Triple roller joint boot |

| q | Check for splits and chafing. |

| 12 - | Clamp |

| q | Renew each time after removing. |

| q | Tightening → Anchor. |

| 13 - | Joint body |

| 14 - | Multi-point socket head bolt |

| q | M8 x 18; |

| Torque settings: → |

| 15 - | Rollers |

| 16 - | Triple roller star |

| The chamfer -arrow- points towards drive shaft splines. |

| 17 - | Retaining ring |

| q | Renew. |

| q | Insert in groove in shaft. |

| 18 - | O-ring |

| Is no longer required for assembly. |

| 19 - | Rectangular section seal |

| This oil seal is part of the repair set. It is not installed during manufacture. |

| No longer supplied as a spare part; instead, a new repair set is supplied. |

| 20 - | Cover |

| Will be destroyed when dismantled. |

| No longer required for assembly and is therefore not supplied as a spare part. |

| New cover is included in repair kit. |