Golf Mk5

| Dismantling and assembling differential |

| Special tools and workshop equipment required |

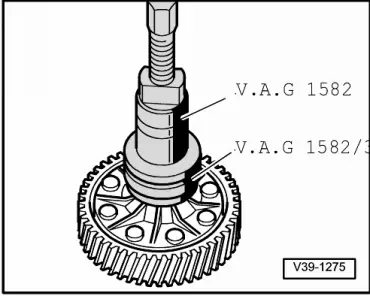

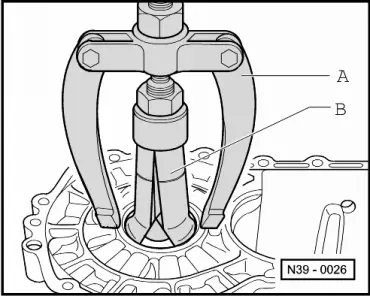

| t | Tapered roller bearing puller -V.A.G 1582- |

| t | Adapter -V.A.G 1582/3- |

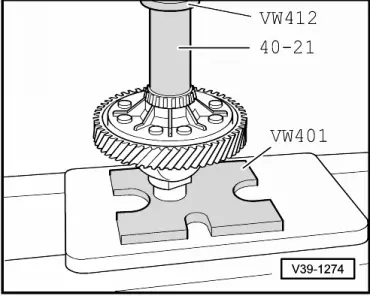

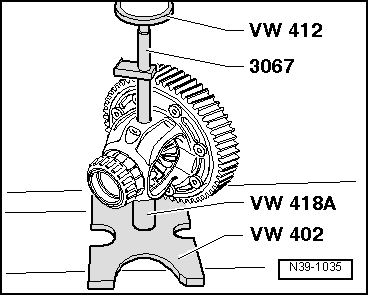

| t | Press tool -VW 412- |

| t | Pressure plate -VW 401- |

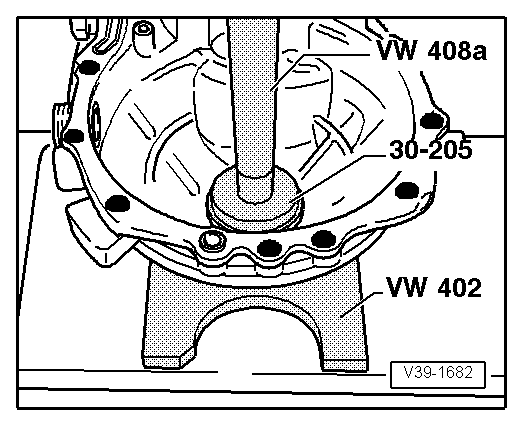

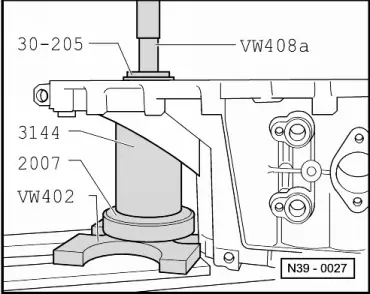

| t | Pressure plate -VW 402- |

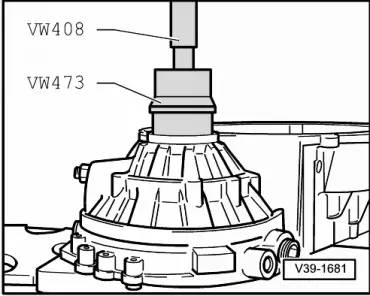

| t | Press tool -VW 408 A- |

| t | Thrust piece -VW 473- |

| t | Thrust plate -30 - 205- |

| t | Sleeve -3144- |

| t | Thrust piece -2007- |

| t | Torque wrench -V.A.G 1332- |

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

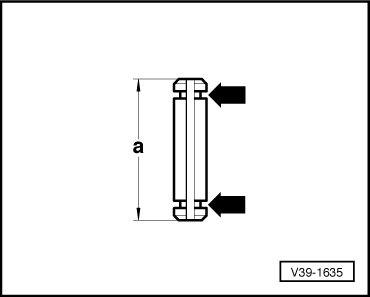

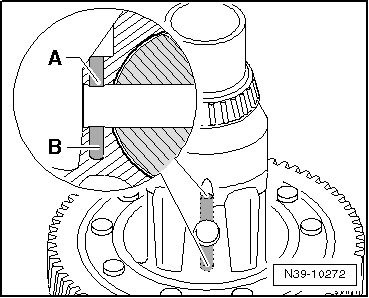

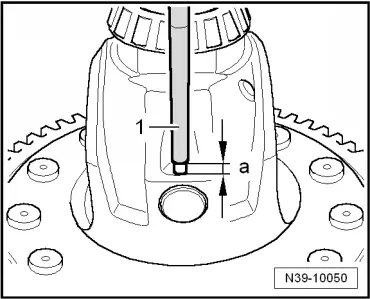

| Dim. „a“ mm | Identification |

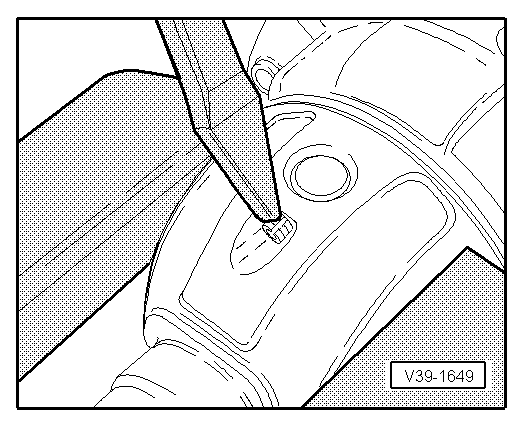

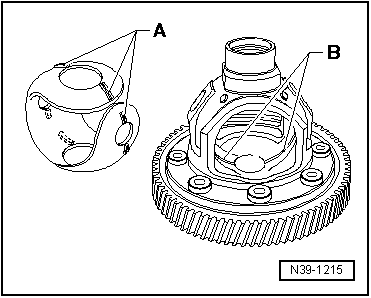

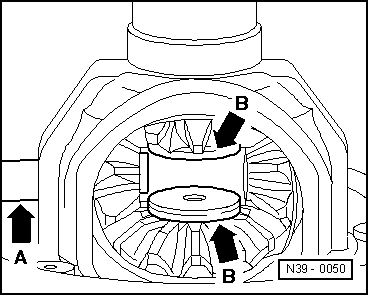

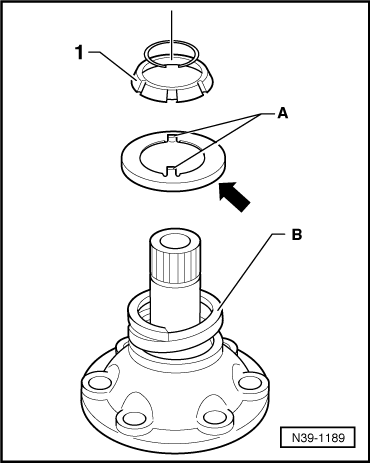

| 28.5 (short spring pin) Removing and installing → Fig. | Circumferential groove -arrows- |

| 36.0 (long spring pin), Removing → Fig., Installing → Fig. | No circumferential groove |

|

|

| Hole | Length of spring pin (mm) |

| -A- | 28.5 (short spring pin) |

| -A- and -B- | 36.0 (long spring pin) |

|

|

|

|

|

|

|

|

|

|

|

|