Golf Mk5

| Repairing selector forks |

| Special tools and workshop equipment required |

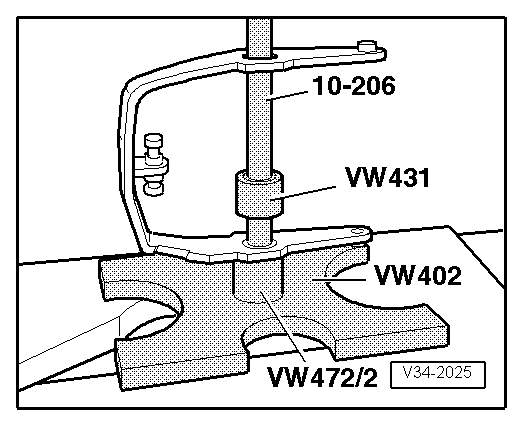

| t | Pressure plate -VW 402- |

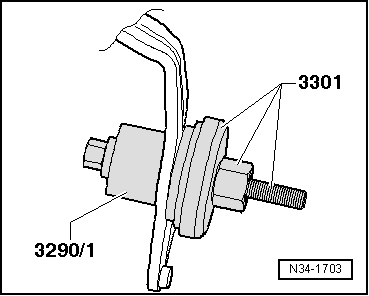

| t | Thrust piece -3290/1- |

| t | Assembly tool -3301- |

| t | Thrust piece -VW 431- |

| t | Spacer sleeve -VW 472/2- |

| t | Drift -10 - 206- |

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

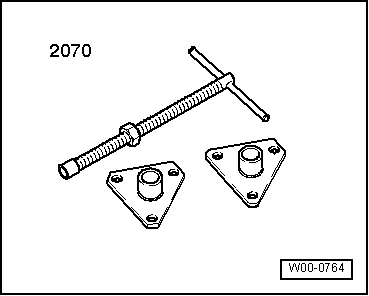

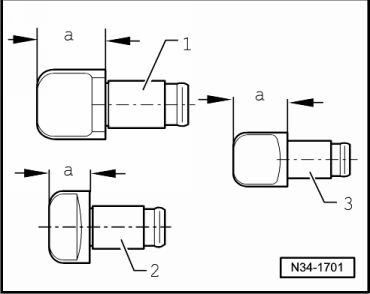

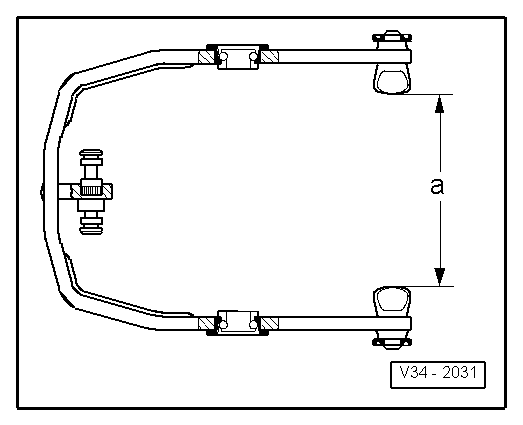

| Dim. -a- (mm) | |

| 1st/2nd gear selector fork | 87.2 …87.4 |

| 3rd/4th gear selector fork | 93.6 …93.8 |

|