Golf Mk5

| Renewing oil seal for propshaft drive flange at bevel box |

| Special tools and workshop equipment required |

| t | Support clamp -VW 313- |

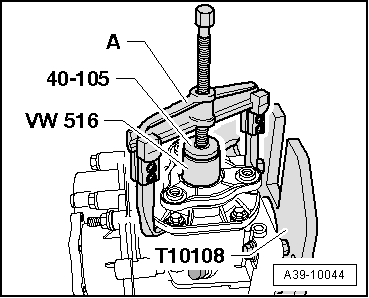

| t | Tube -VW 516- |

| t | Thrust plate -40-105- |

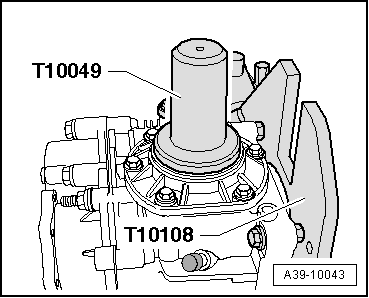

| t | Thrust piece -T10049- |

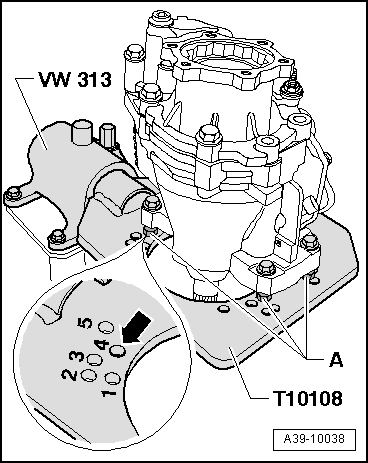

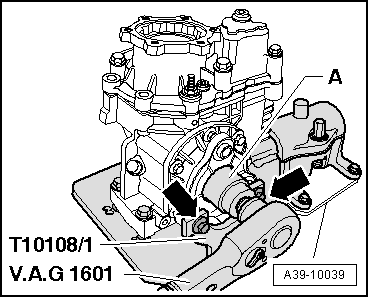

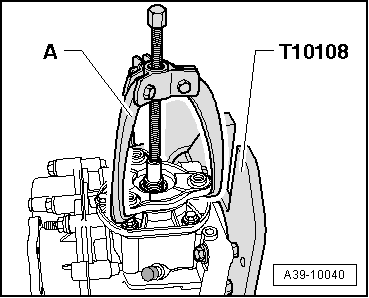

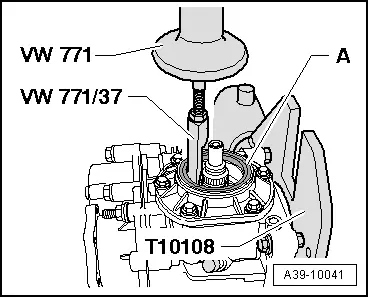

| t | Gearbox support -T10108- |

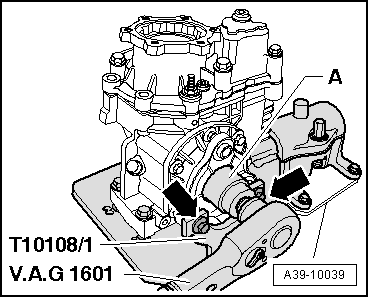

| t | Support plate -T10108/1- |

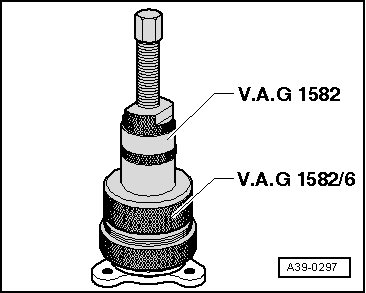

| t | Tapered roller bearing puller -V.A.G 1582- |

| t | Adapter -V.A.G 1582/6A- |

| t | Torque wrench -V.A.G 1601- |

| t | -1- Two-arm puller KUKKO 20/10 |

| t | Three-arm puller KUKKO 45-2 |

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|