Golf Mk5

|

|

|

|

|

|

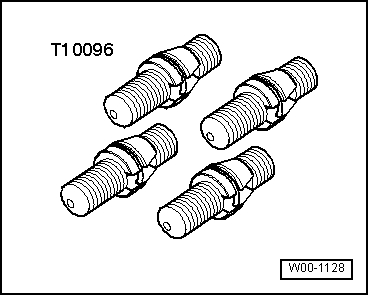

| Special tools and workshop equipment required |

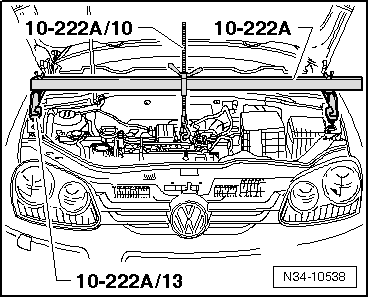

| t | Support bracket -10-222A- |

| t | Adapter -10-222A/3- |

| t | Hook- 10-222A/13- |

| t | Gearbox support -3282- |

| t | Adjustment plate -3282/42 A- |

| t | Insert tool 18 mm -T10179- |

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|