| –

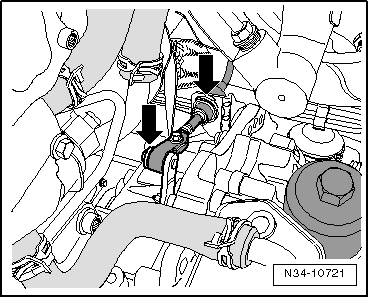

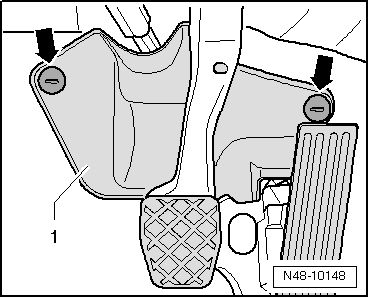

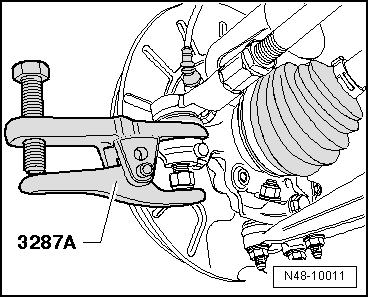

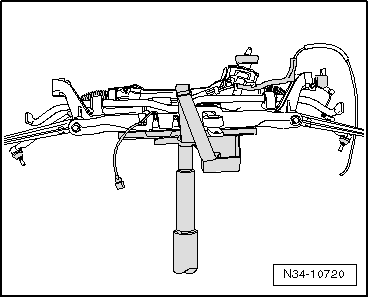

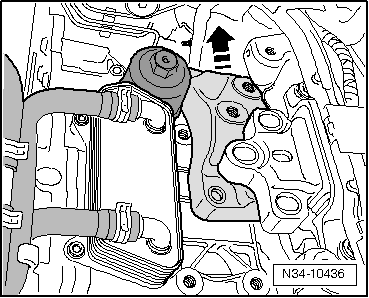

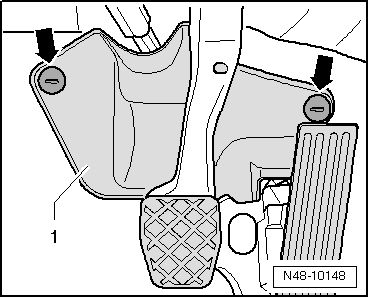

| Now separate steering from steering column. |

| In any case, first return the steering wheel to the straight-ahead position. Engage steering wheel lock. Notes on tightening the bolt can also be found in these instructions. |

| –

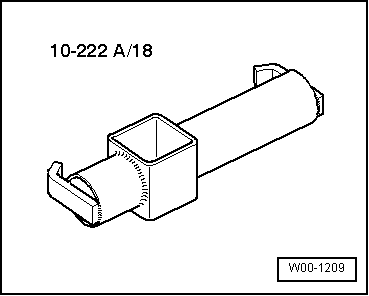

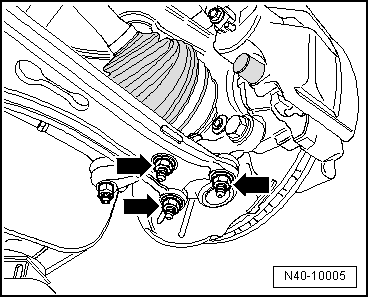

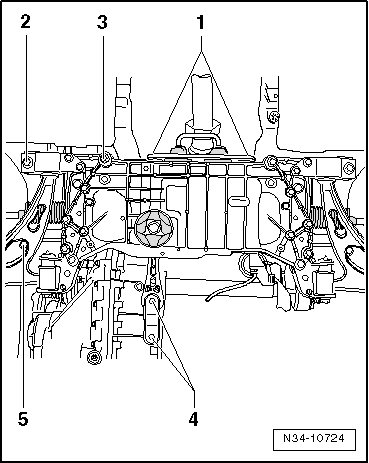

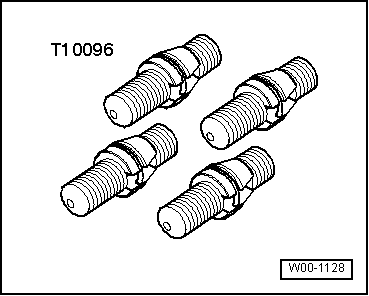

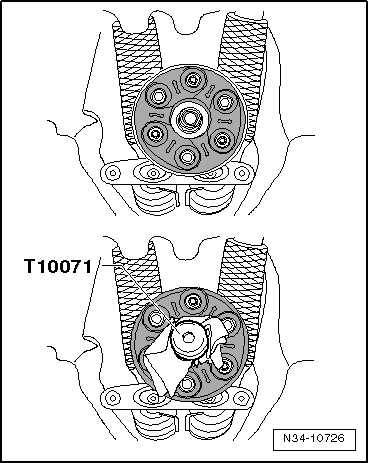

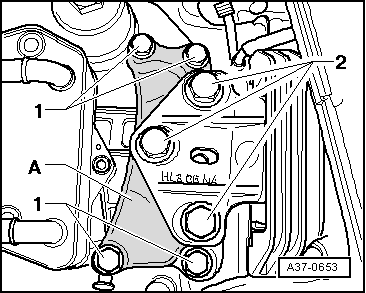

| Now remove all upper connecting bolts between gearbox and engine. Insert 18 mm -T10179- is especially good for this purpose. |

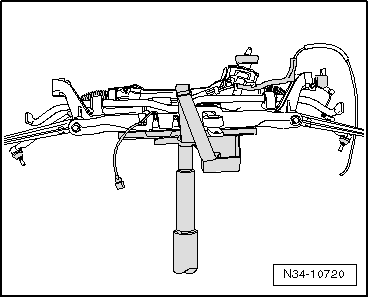

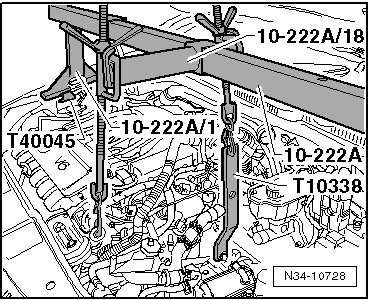

| It is advisable to now do all the work which must be done »beneath« the car. This will avoid having the weight of the engine carried by the support bracket and, consequently, by the body, for »a long time«. |

|

|

|

Note

Note