Golf Mk5

| Front-wheel drive - dismantling and assembling differential |

| Special tools and workshop equipment required |

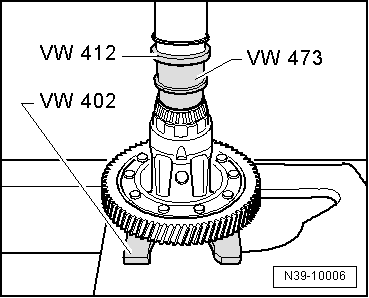

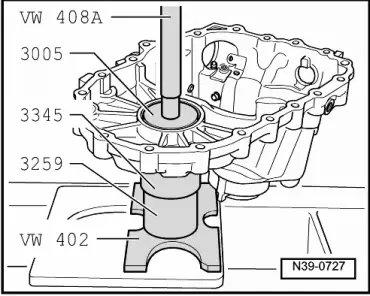

| t | Pressure plate -VW 402- |

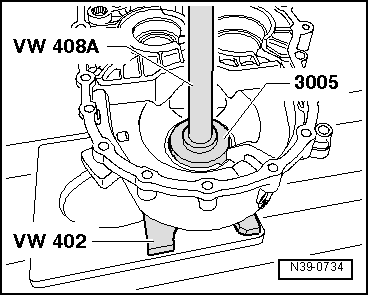

| t | Press tool -VW 408 A- |

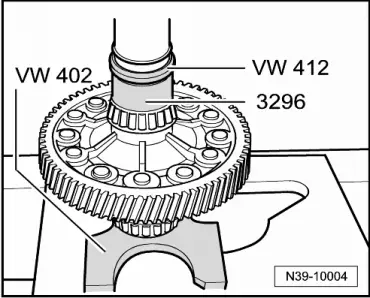

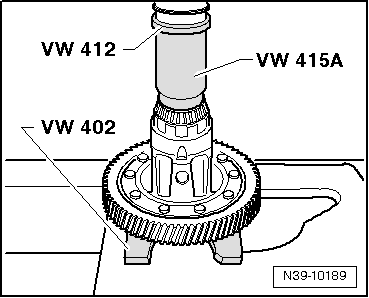

| t | Press tool -VW 412- |

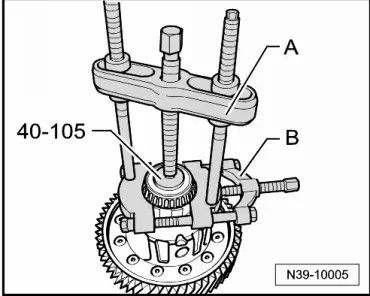

| t | Thrust plate -40-105- |

| t | Thrust plate -3005- |

| t | Only gearboxes with right stub shaft |

| t | Thrust piece -VW 473- |

|

|

|

| t | Tube -3259- |

| t | Tube -3296- |

| t | Tube -3345- |

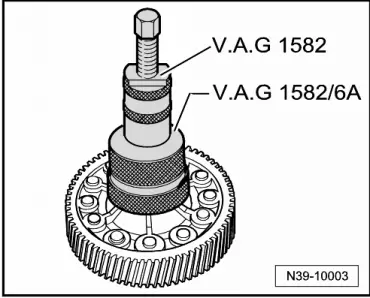

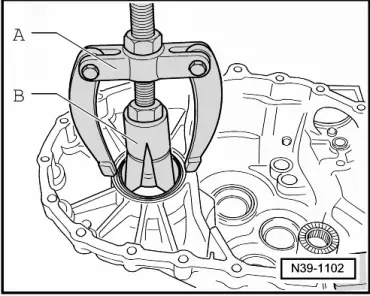

| t | Tapered roller bearing puller -V.A.G 1582- |

| t | Adapter -V.A.G 1582/6A- |

| t | -1-Internal puller -Kukko 21/7- |

| t | -2-Puller -Kukko 18/1- |

| t | -3-Splitter -Kukko 17/1- |

| t | -4-Counter support -Kukko 22/2- |

Note

Note| t | Heat tapered roller bearing inner race to 100 °C before installing. |

| t | Always renew both tapered roller bearings together as a set. |

| t | If tapered roller bearings, differential cage, gearbox housing or clutch housing is renewed, adjust differential → Chapter. |

| 1 - | Gearbox housing |

| 2 - | Shim |

| q | For differential |

| q | Determining thickness → Chapter |

| 3 - | Tapered roller bearing outer race |

| q | Pulling out → Fig. |

| q | Pressing in → Fig. |

| 4 - | Tapered roller bearing inner race |

| q | Pulling off → Fig. |

| q | Pressing on → Fig. |

| 5 - | Differential cage |

| q | With riveted final drive gear |

| q | Support -arrow- for right tapered roller bearing 12.5 mm longer beginning with introduction of right flange shaft. |

| Allocation → Electronic parts catalogue „ETKA“ |

| 6 - | Tapered roller bearing inner race |

| q | Pulling off → Fig. |

| q | Gearbox with right stub shaft: pressing on → Fig. |

| q | Gearbox with right flange shaft: pressing on → Fig. |

| 7 - | Tapered roller bearing outer race |

| q | Pulling out → Fig. |

| q | Pressing in → Fig. |

| 8 - | Washer |

| Installation position: shoulder on inner circumference faces clutch housing |

| Allocation → Electronic parts catalogue „ETKA“ |

| 9 - | Clutch housing |

| 10 - | O-ring |

| q | Always renew |

| 11 - | Protective ring |

| q | Can be pulled off or pushed onto stub shaft → Item by hand |

| 12 - | Countersunk bolt, 33 Nm |

| q | Screw into threaded piece → Item |

| 13 - | Stub shaft |

| q | From gearbox date 01 11 4, replaced with a flange shaft → Item |

| Allocation → Electronic parts catalogue „ETKA“ |

| 14 - | Seal |

| q | Through gearbox date 31 10 4, for stub shaft |

| q | Renewing with gearbox installed → Chapter |

| 15 - | Right flange shaft |

| q | Replaces stub shaft from gearbox date 01 11 4 → Item |

| Allocation → Electronic parts catalogue „ETKA“ |

| 16 - | Protective ring |

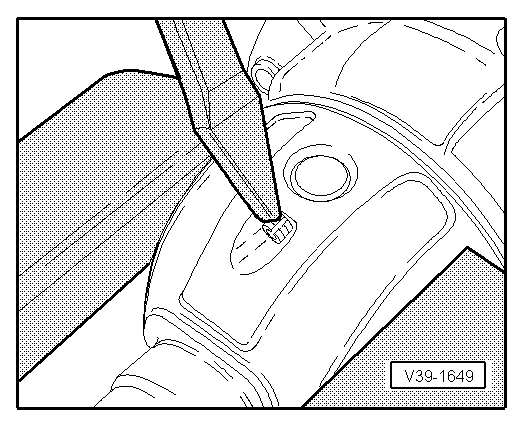

| q | Pry protective ring off flange shaft with a screwdriver, alternating sides → Item |

| q | Push on protective ring to stop by hand |

| q | Protective ring must engage in flange shaft |

| 17 - | Seal |

| q | For flange shaft from gearbox date 01 11 4 → Item |

| q | Renewing with gearbox installed → Chapter |

| Allocation → Electronic parts catalogue „ETKA“ |

| 18 - | Compression spring for flange shaft or stub shaft |

| q | Installed behind flange shaft or stub shaft |

| 19 - | Thrust washer |

| q | Installation position: shoulder faces spring, lugs, if present, face tapered ring |

| 20 - | Tapered ring |

| q | Installation position: taper towards differential cage |

| 21 - | Retaining ring |

| q | Holds tapered ring, thrust washer and spring in position when flange shaft or stub shaft is removed |

| 22 - | Large differential bevel gear |

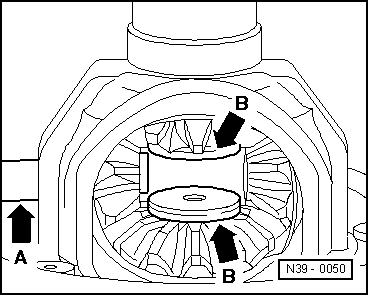

| q | Installing → Fig. |

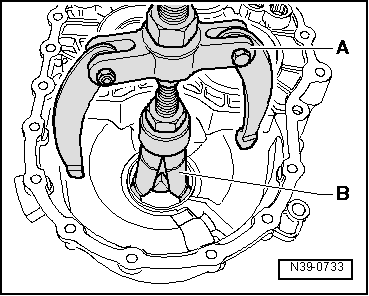

| 23 - | Differential pinion pin |

| q | Drive out using drift |

| q | Installing → Fig. |

| 24 - | Spring pin |

| q | For securing differential pinion pin |

| q | Removing and installing → Fig. |

| 25 - | Small differential bevel gear |

| q | Removing and installing → Fig. |

| 26 - | Threaded piece |

| q | Installing → Fig. |

| 27 - | One-piece thrust washer |

| q | Coat with gear oil when installing |

| 28 - | Protective ring |

| q | Pry off protective ring using screwdriver on alternate sides |

| q | Install with indentation facing away from threaded hole in flange shaft |

| q | Push on protective ring to stop by hand |

| q | Protective ring must engage in flange shaft |

| 29 - | Flange shaft |

| 30 - | Seal |

| q | For flange shaft |

| Allocation → Electronic parts catalogue „ETKA“ |

| q | Renewing with gearbox installed → Chapter. |

Note

Note

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|