| –

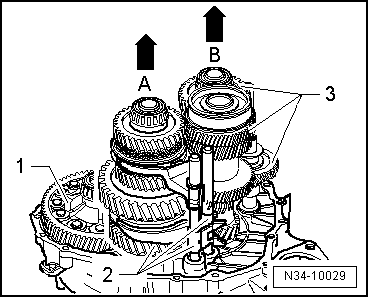

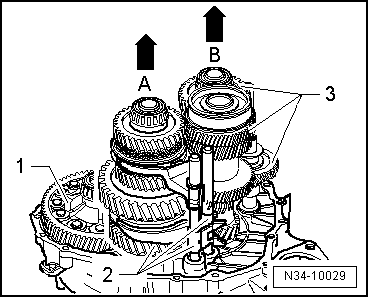

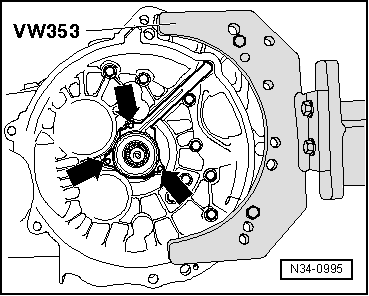

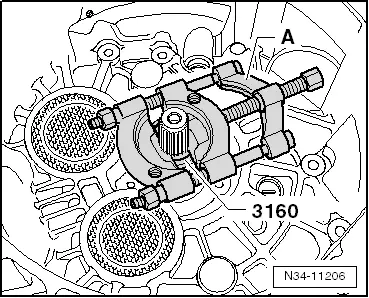

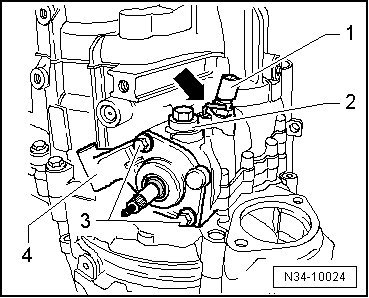

| With left hand, raise differential -1-. With right hand, lift output shaft for 1st to 4th gear together with selector rods -2--arrow A-. |

| –

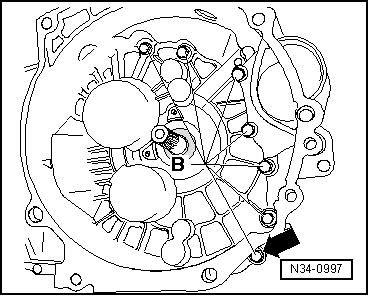

| At same time, second mechanic lifts input shaft, reverse shaft and output shaft for reverse, 5th and 6th gears -3- together with selector rods out of clutch housing -arrow B-. |

Note | After shafts are lifted, differential may be set back in clutch housing if desired. |

| –

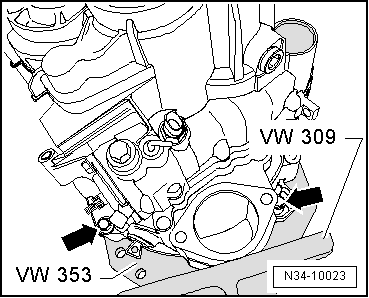

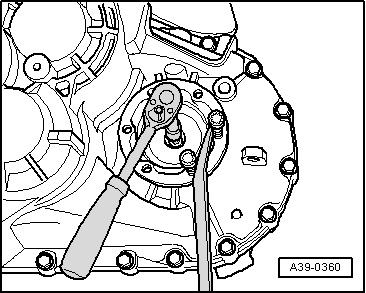

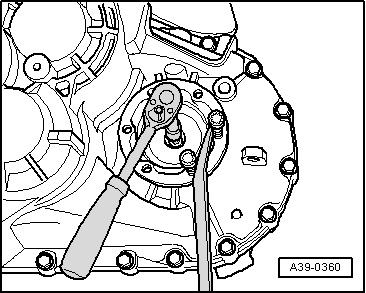

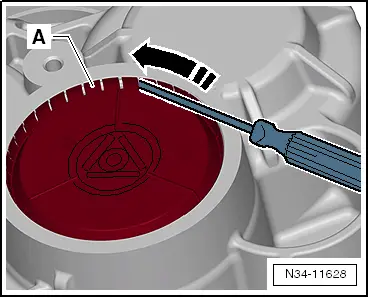

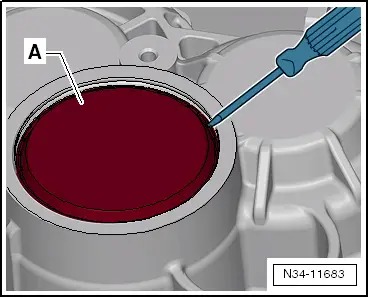

| Lever out input shaft oil seal using oil seal extractor lever -VW 681-. |

Note | Always renew deep groove ball bearing on input shaft → Item. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note Note

Note