| –

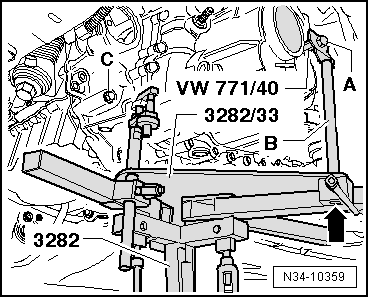

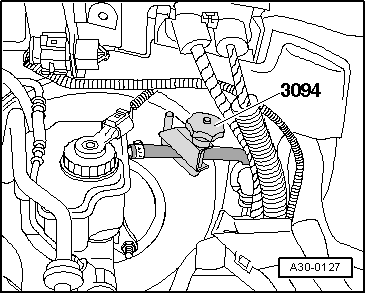

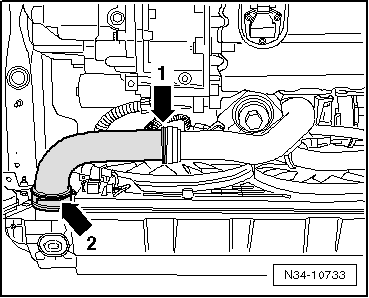

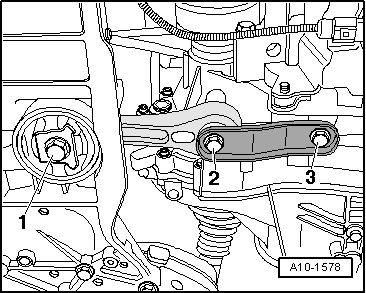

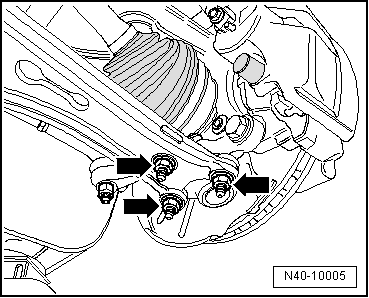

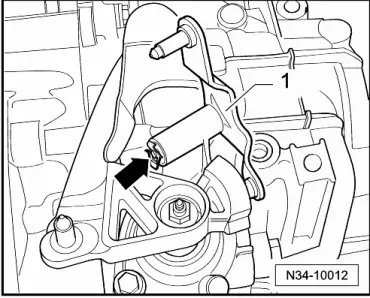

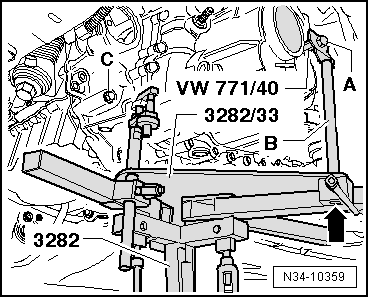

| Secure adapter -VW 771/40- in threaded hole of gearbox housing as shown in figure. |

| –

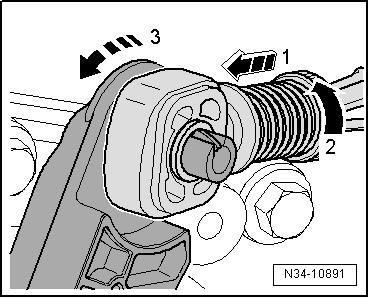

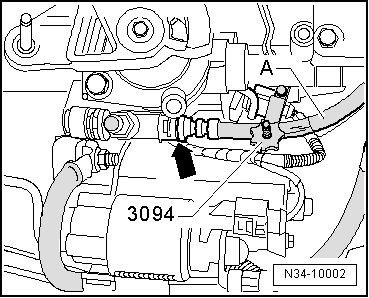

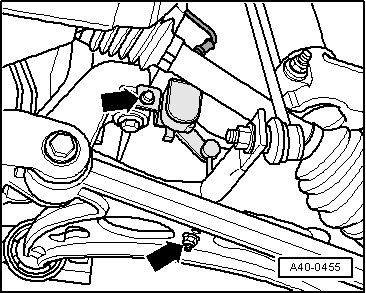

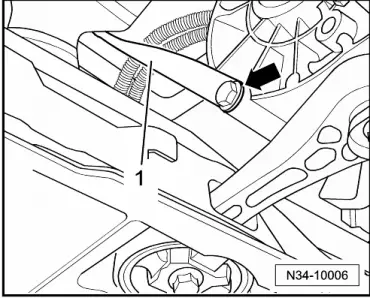

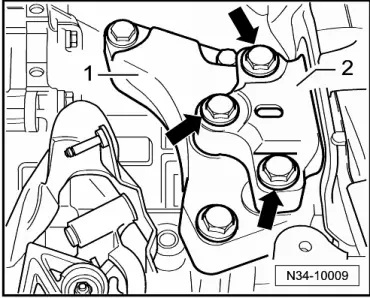

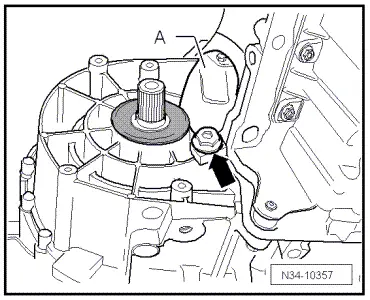

| Screw pin -3282/29- into hole on gearbox for securing bolt of pendulum support. |

| –

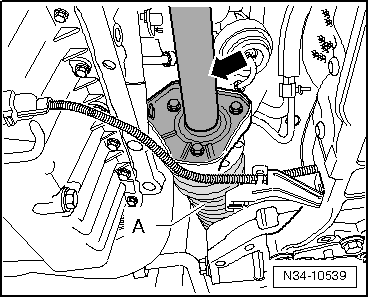

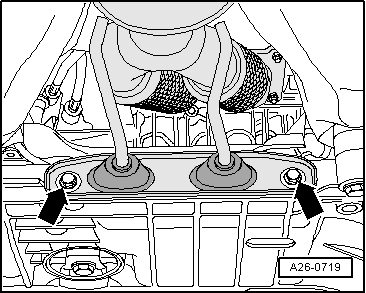

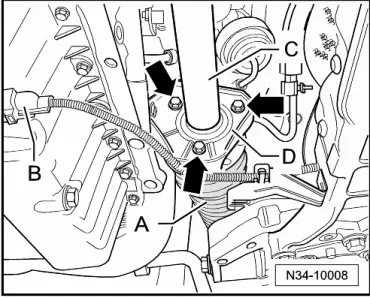

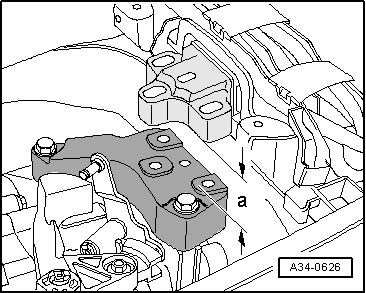

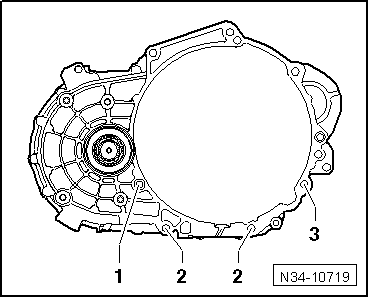

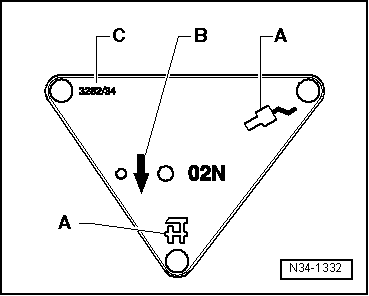

| Secure gearbox to gearbox support -3282- using bolt (M10x20) -A-. |

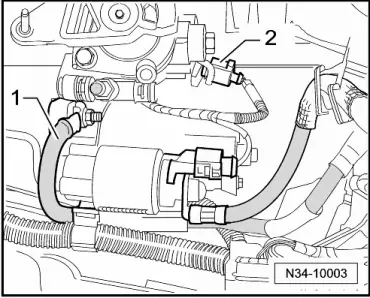

| Pin -B- must lie flush with guide from gearbox support -3282- at bottom -arrow-. |

| –

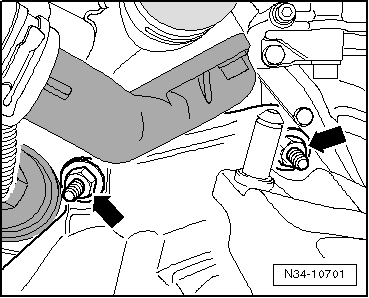

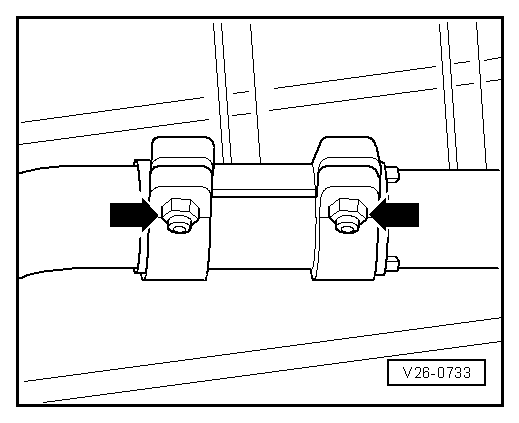

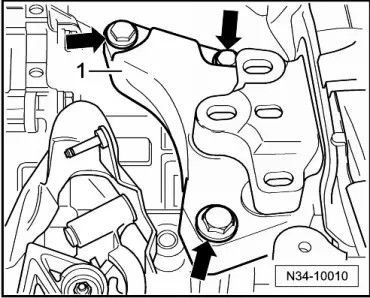

| Remove last engine/gearbox connecting bolt -C-. |

| –

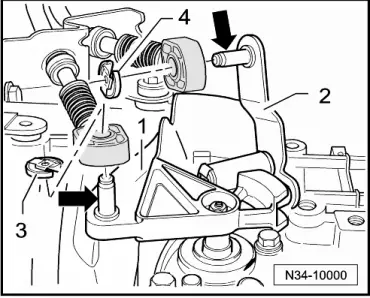

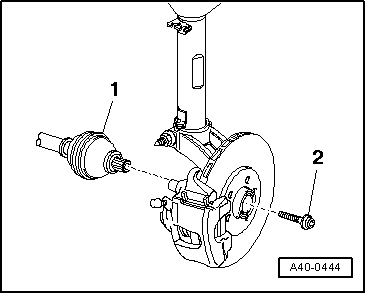

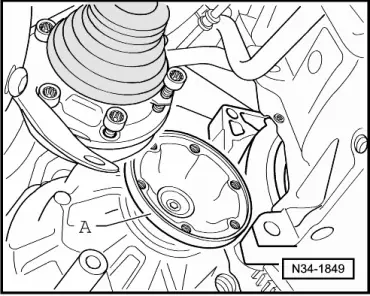

| Press gearbox away from engine, off dowel sleeves. |

| –

| Raise gearbox near differential via spindle of gearbox support -3282-. |

| –

| Rotate gearbox to left via spindle of gearbox support -3282-. |

| –

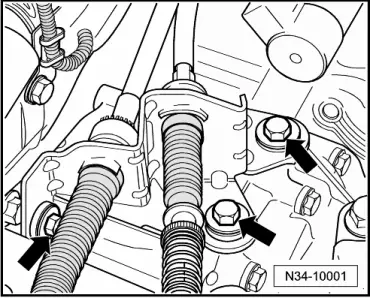

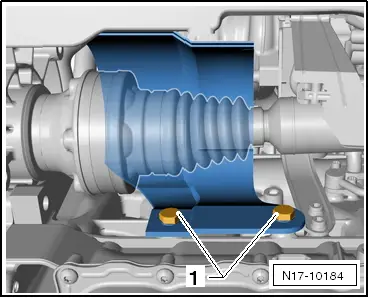

| Lower gearbox carefully. |

Note | t

| When lowering gearbox, observe, if appropriate, steering box. |

| t

| Be careful of all lines when lowering gearbox. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Caution

Caution