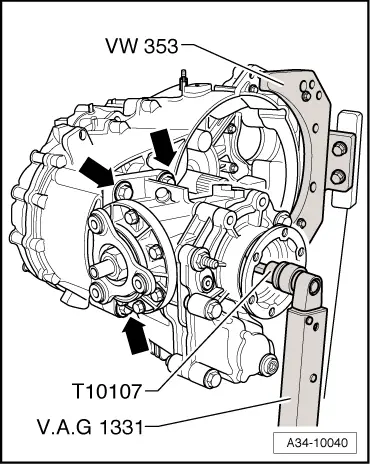

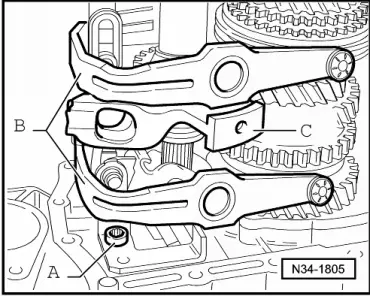

| Attach bevel box to gearbox as follows: |

| –

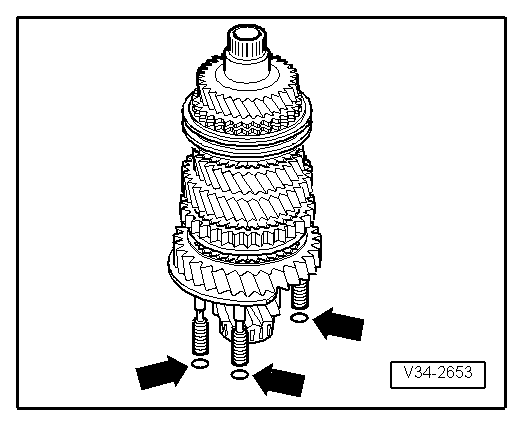

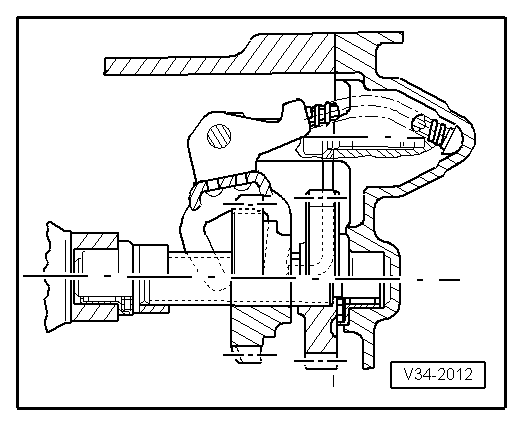

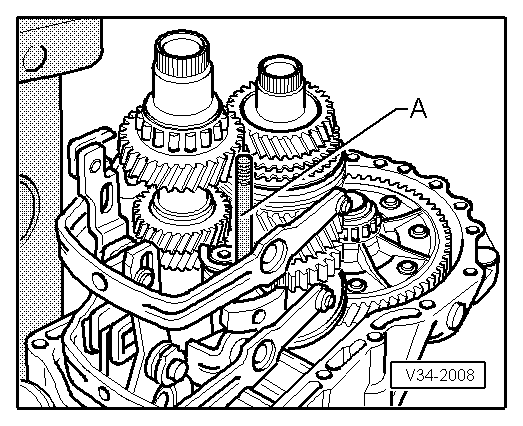

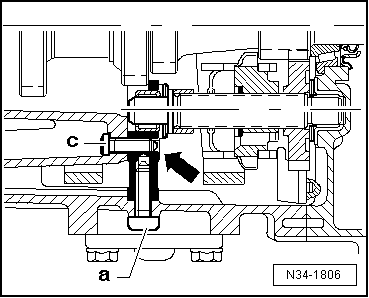

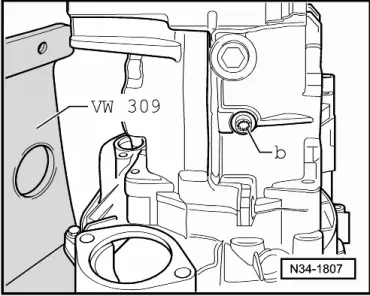

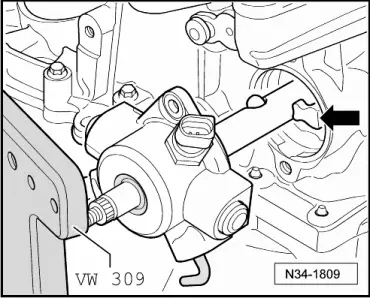

| Push bevel box completely onto gearbox, ensuring that splines of bevel box input shaft and differential are centred when brought together. |

| –

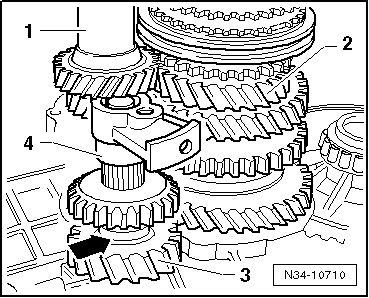

| Align splines of right flange shaft and differential bevel gear, turning flange shaft if necessary. |

| –

| If splines are correctly positioned and shafts are centred, then bevel box will slide to stop against gearbox. |

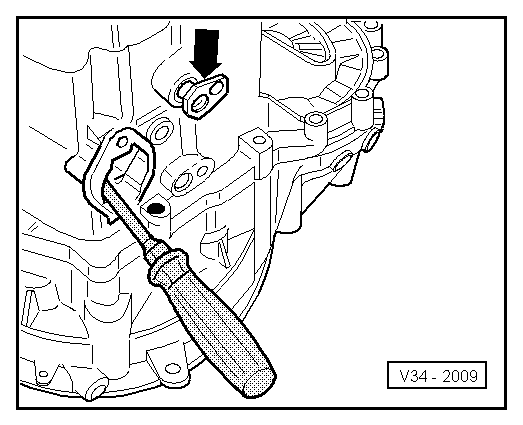

Note | Do not use securing bolts to pull bevel box onto gearbox, or bevel box will cant and bolt holes can break off. |

|

|

|

Note

Note

Note

Note

Note

Note