Golf Mk5

| Dismantling and assembling output shaft |

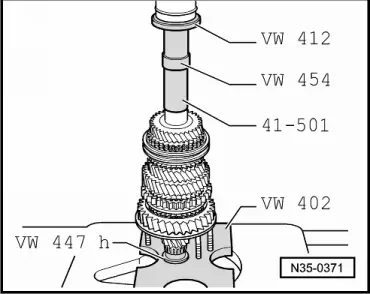

| Special tools and workshop equipment required |

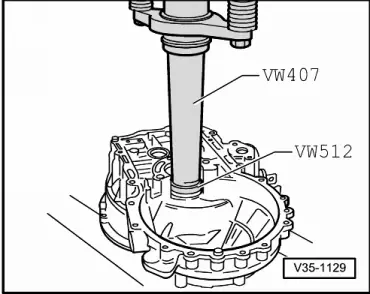

| t | Press tool -VW 407- |

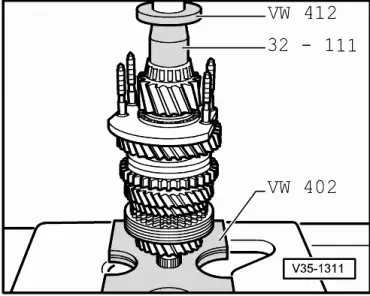

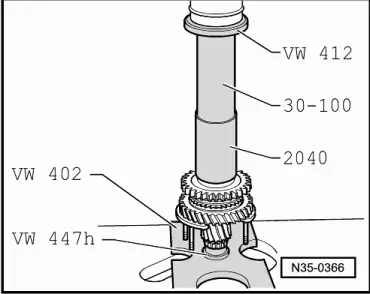

| t | Press tool -VW 412- |

| t | Thrust pad -VW 512- |

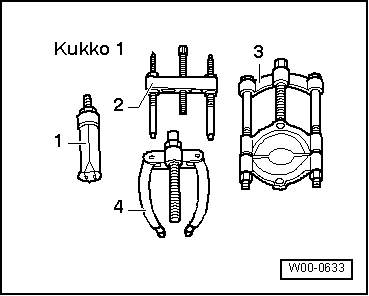

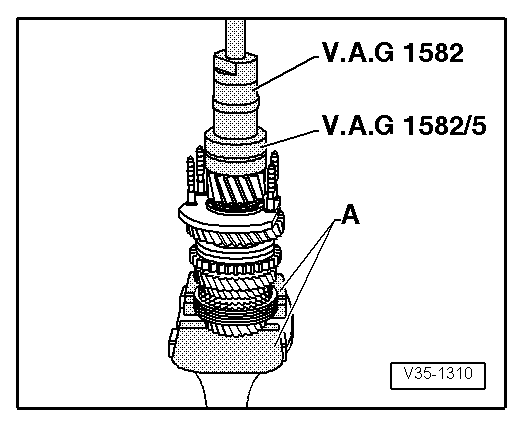

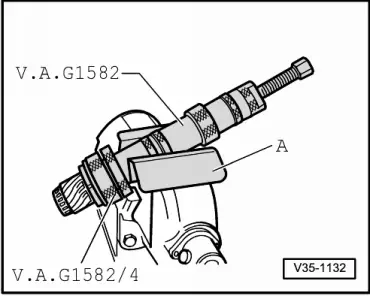

| t | Puller -V.A.G 1582- |

| t | Adapter -V.A.G 1582/4- |

| t | Adapter -V.A.G 1582/5- |

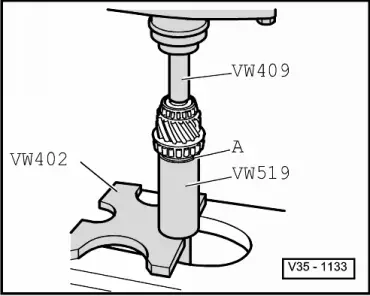

| t | Thrust plate -VW 402- |

| t | Thrust piece -32 - 111- |

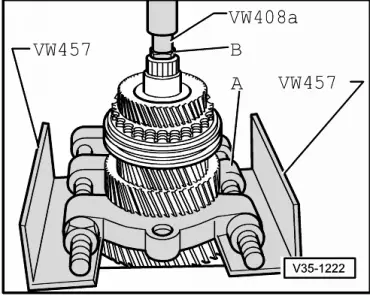

| t | Press tool -VW 408 A- |

| t | Press tool -VW 409- |

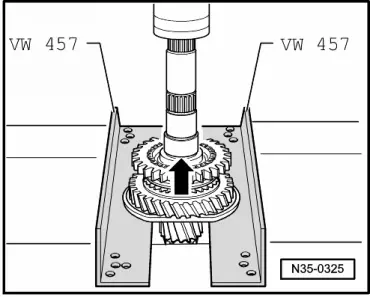

| t | Support rails -VW 457- |

| t | Tube -VW 519- |

| t | Drift sleeve -30 - 100- |

| t | Tube -VW 415 A- |

| t | Thrust pad -VW 447 H- |

| t | Thrust piece -VW 454- |

| t | Tube -2040- |

| t | Drift sleeve -41 - 501- |

|

|

|

|

Note

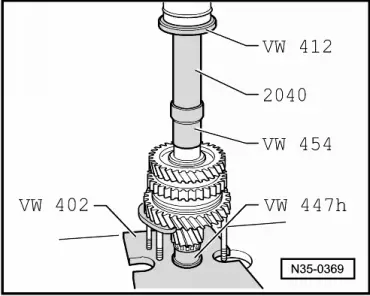

Note| t | The output shaft is dismantled as follows: position separating device under 2nd gear synchromeshed gear → Item and press off as described in → Fig.. Remove retaining ring → Item. Then press off locking collar with synchro-hub for 1st and 2nd gear as described in → Fig.. |

| t | When installing new gears or new input shaft, refer to → Electronic parts catalogue “ETKA” and technical data → Chapter. |

| t | Always renew both tapered roller bearings together as a set. |

| 1 - | Hexagon nut, 25 Nm and then turn 90° further |

| q | 4 nuts for bearing support. |

| q | Always renew |

| 2 - | Clutch housing |

| 3 - | Shim |

| q | For output shaft |

| q | Adjustment overview → Chapter |

| 4 - | Small tapered roller bearing outer race |

| q | Removing → Fig. |

| q | Pressing in → Fig. |

| 5 - | Small tapered roller bearing inner race |

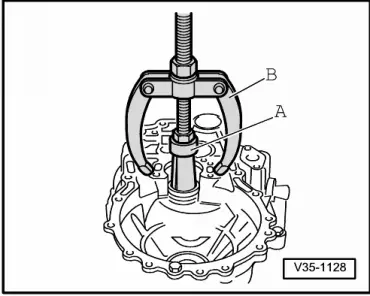

| q | Pulling off → Fig. |

| q | Pressing on → Fig. |

| 6 - | Output shaft |

| q | Adjusting → Chapter |

| 7 - | Large tapered roller bearing inner race |

| q | Pulling off → Fig. |

| q | Pressing on → Fig. |

| 8 - | Seal |

| q | Place sealing rings (Qty. 4) on bearing support bolts |

| 9 - | Bearing support |

| q | With large tapered roller bearing outer race and bolts |

| q | Change outer race only together with large tapered roller bearing and bearing support |

| 10 - | Thrust washer |

| q | Shoulder of thrust washer faces tapered roller bearing |

| 11 - | Synchromeshed gear for 1st gear |

| 12 - | Needle bearing |

| q | For 1st gear |

| 13 - | Synchro-ring |

| q | (Inner ring for 1st gear) |

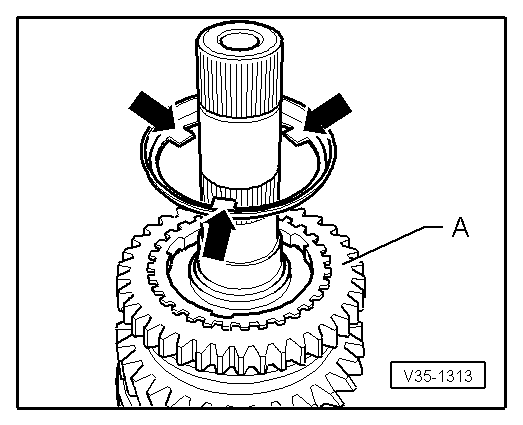

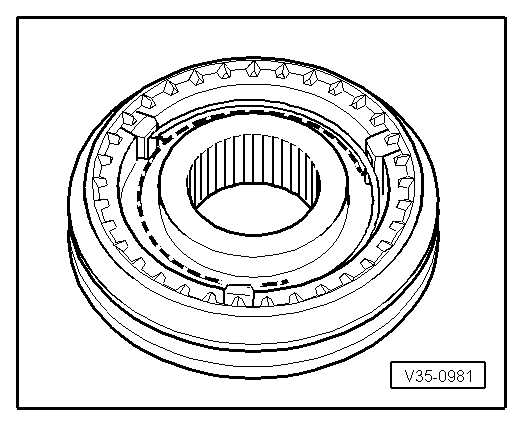

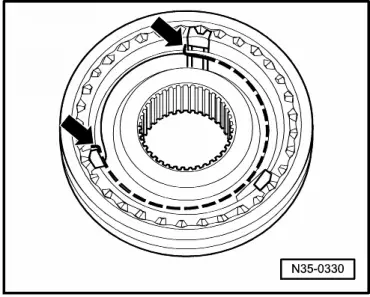

| q | Installation position → Fig. |

| q | Check for wear → Fig. |

| q | Check lugs for scoring |

| 14 - | Outer ring for 1st gear |

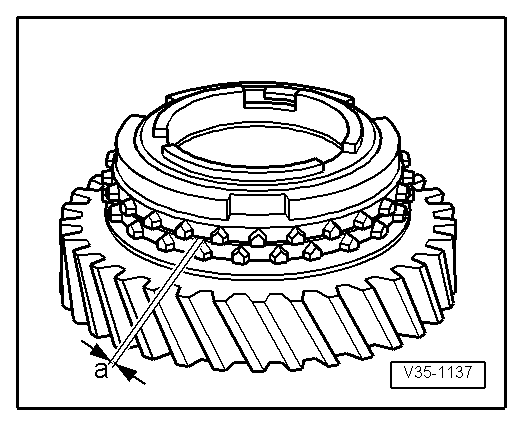

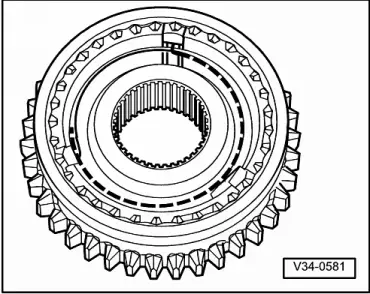

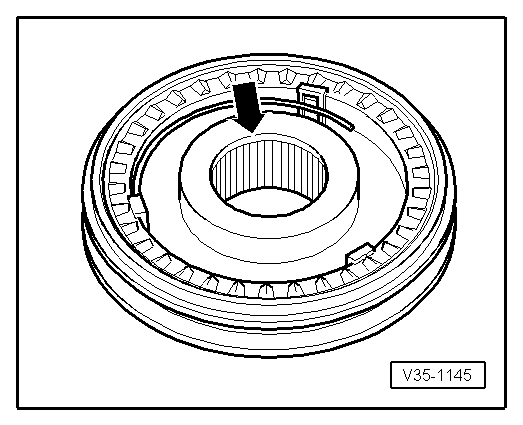

| q | Installation position → Fig. |

| q | Check for wear → Fig. |

| q | Renew if scored |

| 15 - | Synchro-ring for 1st gear |

| q | Installation position → Fig. |

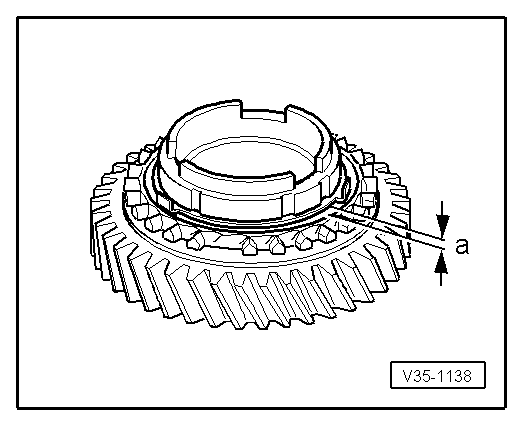

| q | Check for wear → Fig. |

| 16 - | Locking collar with synchro-hub for 1st and 2nd gears |

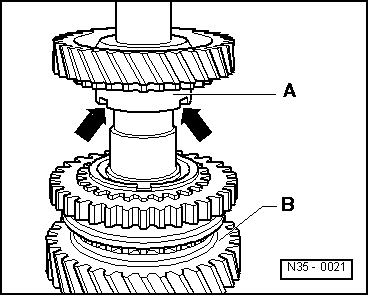

| q | After removing retaining ring, pull off together with bearing support → Fig. → Item |

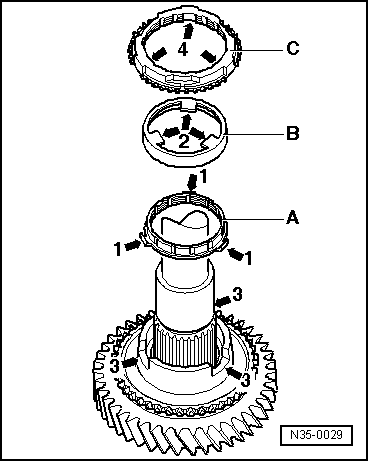

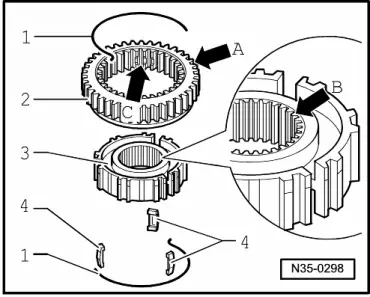

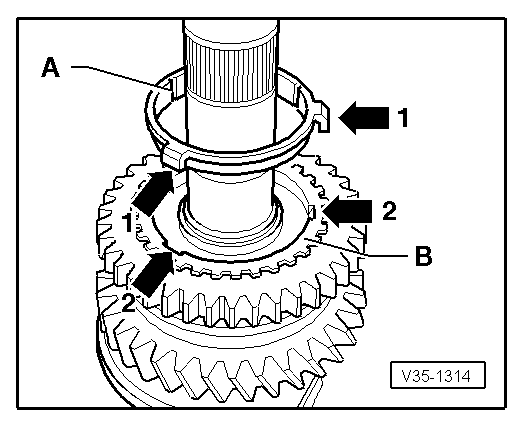

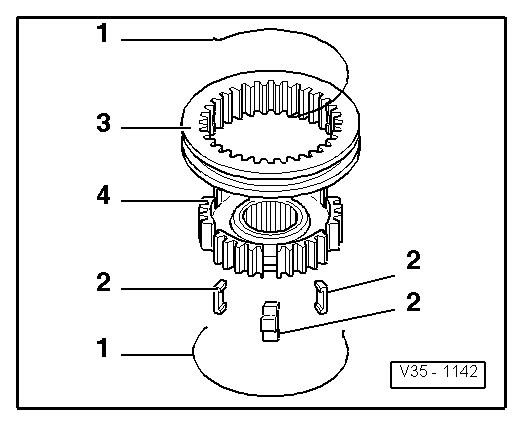

| q | Dismantling → Fig. |

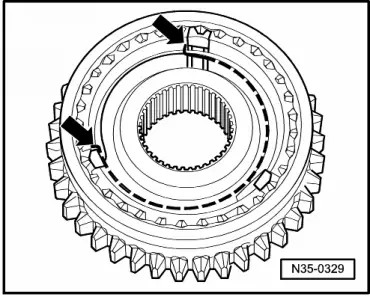

| q | Assembling locking collar and synchro-hub → Fig., → Fig. and → Fig. |

| q | Installation position → Fig. |

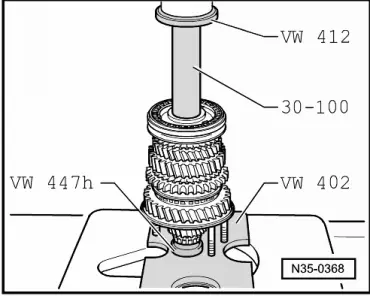

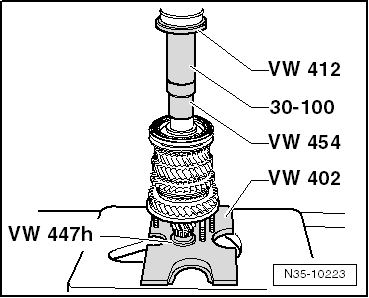

| q | Pressing on → Fig. |

| 17 - | Retaining ring |

| 18 - | Synchro-ring for 2nd gear |

| q | Check for wear → Fig. |

| q | Assemble so that notches engage in locking pieces of locking collar → Item |

| 19 - | Outer ring for 2nd gear |

| q | Insert in synchro-ring → Item |

| q | Installation position → Fig. |

| q | Renew if scored |

| 20 - | Synchro-ring |

| q | (Inner ring for 2nd gear) |

| q | Check for wear → Fig. |

| q | Check lugs for scoring |

| q | Installation position → Fig. |

| 21 - | Synchromeshed gear for 2nd gear |

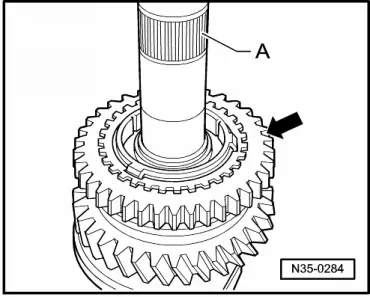

| q | Installation position → Fig. |

| 22 - | Needle bearing |

| q | For 2nd gear |

| 23 - | Thrust washer |

| 24 - | Sleeve for 3rd gear needle bearing |

| q | Pressing off with synchromeshed gear for 2nd gear → Fig. |

| q | Pressing on → Fig. |

| 25 - | Needle bearing |

| q | For 3rd gear |

| 26 - | Synchromeshed gear for 3rd gear |

| 27 - | Synchro-ring for 3rd gear |

| q | Check for wear → Fig. |

| 28 - | Locking collar with synchro-hub for 3rd and 4th gears |

| q | Press off with synchromeshed gears for 2nd gear → Item and 3rd gear → Item → Fig.. |

| q | Dismantling → Fig. |

| q | Assembling locking collar and synchro-hub → Fig., → Fig. and → Fig. |

| q | Installation position, locking collar and synchro-hub → Fig. |

| q | Pressing on → Fig. |

| 29 - | Sleeve |

| q | For needle bearing |

| q | Press off with 3rd and 4th gear → Item locking collar and synchro-hub → Fig.. |

| q | Pressing on → Fig. |

| 30 - | Needle bearing |

| q | For 4th gear |

| 31 - | Synchro-ring for 4th gear |

| q | Check for wear → Fig. |

| 32 - | Synchromeshed gear for 4th gear |

| 33 - | Thrust washer |

| 34 - | Needle bearing |

| q | For output shaft |

| q | Removing and installing → Fig. |

| 35 - | Gearbox housing |

| 36 - | Sleeve |

| q | For output shaft needle bearing |

| q | Pressing off → Fig. |

| q | Pressing on → Fig. |

| 37 - | Gear wheel for 5th gear |

| q | Removing and installing → Chapter |

| 38 - | Sleeve |

| 39 - | Gear wheel for 6th gear |

| q | Removing and installing → Chapter |

| 40 - | Cylindrical roller bearing inner race |

| q | For output shaft |

| q | Larger outer diameter from gearbox date 21 08 6 |

| q | Allocation → Fig. |

| q | Mark before removing |

| q | Do not interchange with inner race for cylindrical roller bearing of input shaft |

| 41 - | Bolt → Item |

| q | Allocation → Fig. |

| q | Self-locking |

| q | Always renew |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

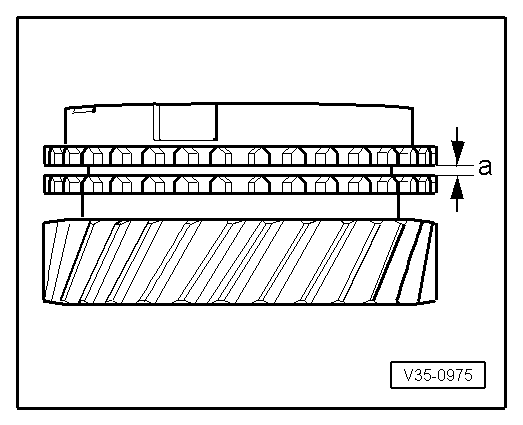

| Gap -a- | Installation (new) dimension | Wear limit |

| 1st and 2nd gears | 0.75…1.25 mm | 0.3 mm |

|

|

| Gap -a- | Installation (new) dimension | Wear limit |

| 1st and 2nd gears | 1.2…1.8 mm | 0.5 mm |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Gap -a- | Installation (new) dimension | Wear limit |

| 1st gear 3rd gear 4th gear | 1.0 ... 1.7 mm 1.0 ... 1.7 mm 1.0 ... 1.7 mm | 0.5 mm |

|

|

|

|

|

|

|

|

|

|

|

|

|

|