Golf Mk5

| Dismantling and assembling differential |

| Special tools and workshop equipment required |

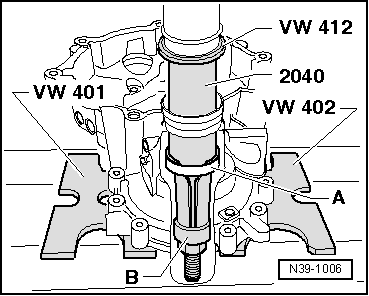

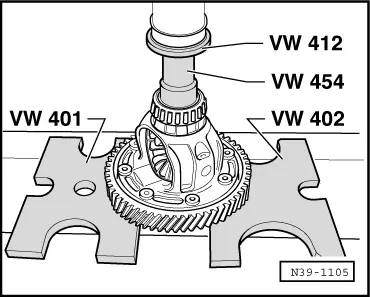

| t | Pressure plate -VW 401- |

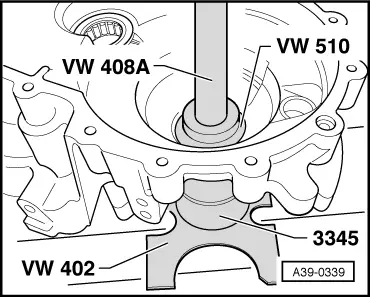

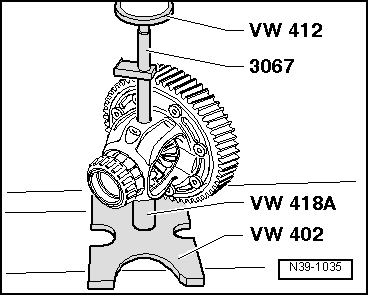

| t | Pressure plate -VW 402- |

| t | Press tool -VW 408 A- |

| t | Press tool -VW 412- |

| t | Tube -VW 418 A- |

| t | Thrust piece -VW 454- |

| t | Installing sleeve -VW 455- |

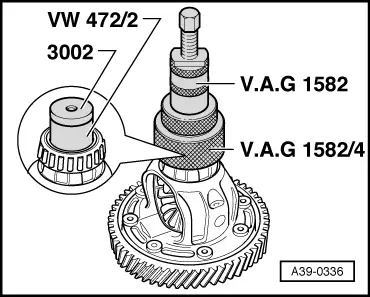

| t | Spacer sleeve -VW 472/2- |

| t | Thrust pad -VW 510- |

| t | Tube -30 - 14- |

| t | Tube -2040- |

| t | Thrust piece -3002- |

| t | Counterhold -3067- |

| t | Tube -3259- |

| t | Wheel bearing tube -3345- |

| t | Tapered roller bearing puller -V.A.G 1582- |

| t | Adapter -V.A.G 1582/4- |

| t | Internal puller -1 - Kukko 21/7- |

| t | Counter support -4 - Kukko 22/2- |

| t | Thrust plate -30 - 205- |

| t | Drift sleeve -40 - 21- |

| t | Torque wrench -V.A.G 1331- (5 ... 50 Nm) |

| t | Adapter -V.A.G 1582/3- |

Note

Note| t | Heat tapered roller bearing inner race to 100° C before installing. |

| t | Always renew both tapered roller bearings together as a set. |

| t | If tapered roller bearings, differential cage, gearbox housing or clutch housing is renewed, adjust differential → Chapter. |

| 1 - | Countersunk bolt, 25 Nm |

| q | Screw into threaded piece → Item |

| 2 - | Right flange shaft |

| 3 - | Compression spring for flange shaft |

| q | Installed behind flange shafts |

| 4 - | Thrust washer |

| q | Installation position: shoulder towards spring |

| 5 - | Tapered ring |

| q | Installation position: taper towards differential cage |

| 6 - | Retaining ring |

| q | Holds tapered ring, thrust washer and spring in position when flange shaft is removed |

| 7 - | Sun wheel |

| q | Installing → Fig. |

| 8 - | Threaded piece |

| q | Installing → Fig. |

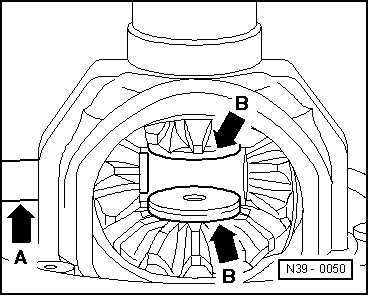

| 9 - | Differential pinion pin |

| q | To remove, shear off spring pin → Item → Fig. |

| q | Installing → Fig. |

| 10 - | Planet pinion |

| q | Installing → Fig. |

| 11 - | One-piece thrust washer |

| q | Coat with gear oil when installing |

| 12 - | Left flange shaft |

| 13 - | Oil seal for left flange shaft |

| q | Renewing with manual gearbox installed → Chapter. |

| 14 - | Shim S1 |

| q | For differential |

| q | Always 1 mm thick |

| q | Shim S1 discontinued as of gearbox date 04 12 6 → Fig. |

| q | Bearing seat for tapered roller bearing outer race adapted in gearbox housing |

| q | Allocation → Electronic parts catalogue (ETKA) |

| 15 - | Tapered roller bearing outer race |

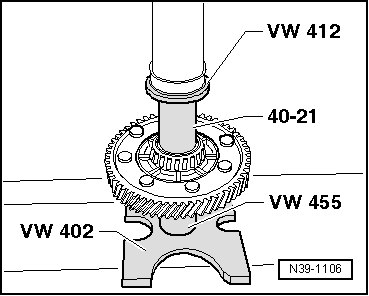

| q | Pulling out → Fig. |

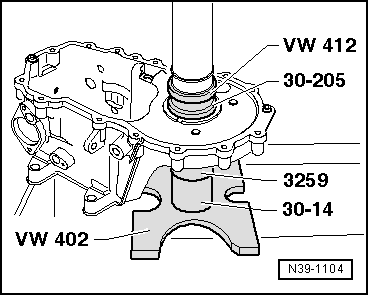

| q | Pressing in → Fig. |

| 16 - | Tapered roller bearing inner race |

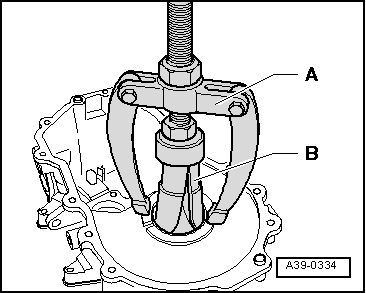

| q | Pulling off → Fig. |

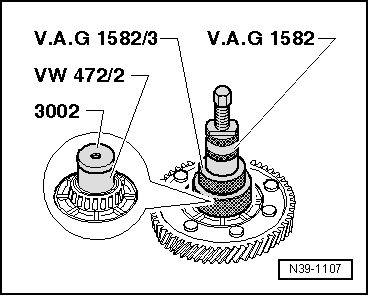

| q | Pressing on → Fig. |

| 17 - | Differential cage |

| q | With final drive gear |

| 18 - | Spring pin |

| q | For securing planet pinion pin |

| q | Will be sheared off when removed → Fig. |

| 19 - | Tapered roller bearing inner race |

| q | Pulling off → Fig. |

| q | Pressing on → Fig. |

| 20 - | Tapered roller bearing outer race |

| q | Pressing out → Fig. |

| q | Pressing in → Fig. |

| 21 - | Shim S2 |

| q | For differential |

| q | Determining thickness → Chapter |

| 22 - | Oil seal for right flange shaft |

| q | Renewing with manual gearbox installed → Chapter. |

| 23 - | Gearbox housing |

| q | Repairing → Chapter |

| q | Shim S1 discontinued as of gearbox date 04 12 6 → Fig. |

| q | Bearing seat for tapered roller bearing outer race adapted |

| q | Allocation → Electronic parts catalogue (ETKA) |

| 24 - | Clutch housing |

| q | Repairing → Chapter |

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

WARNING

WARNING