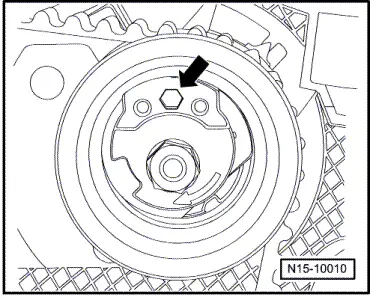

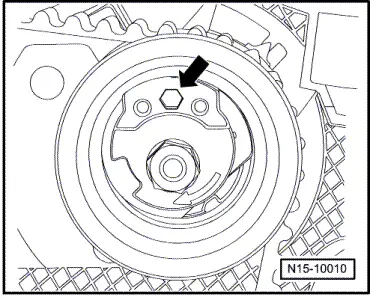

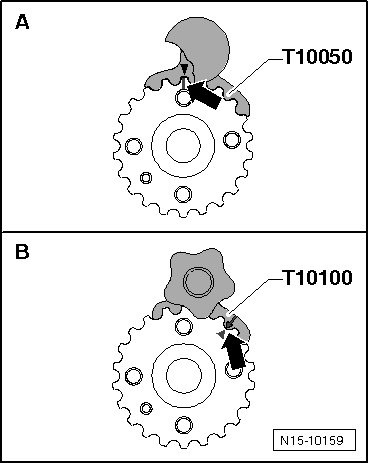

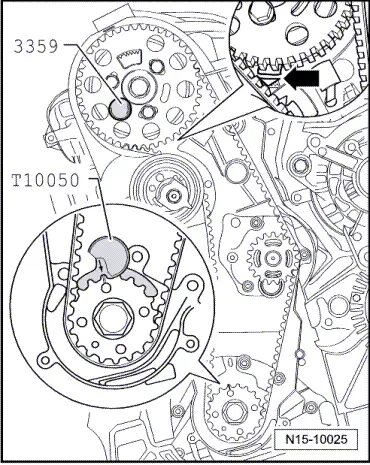

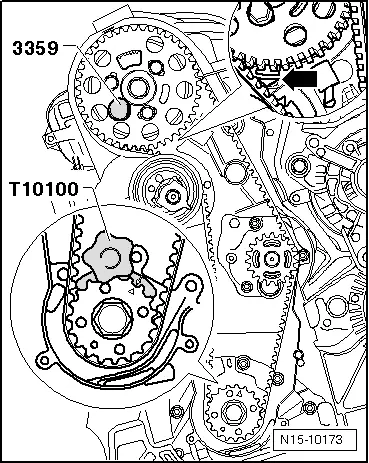

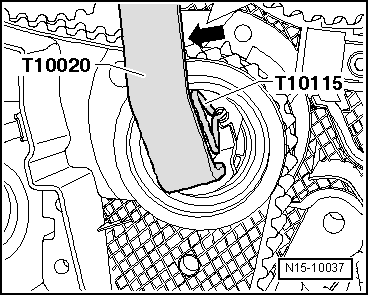

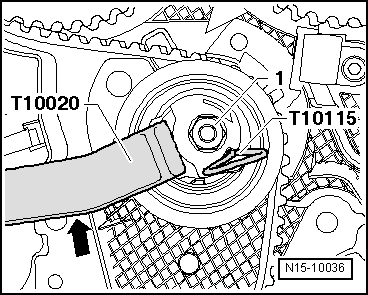

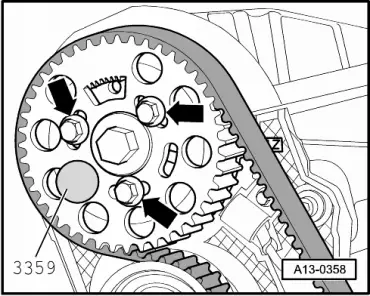

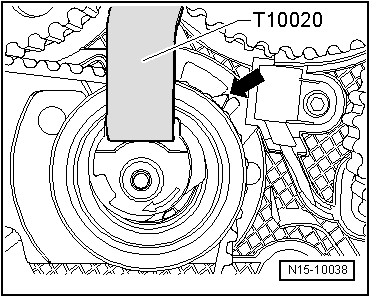

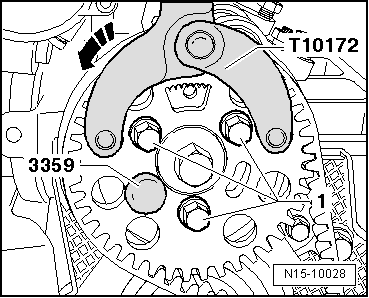

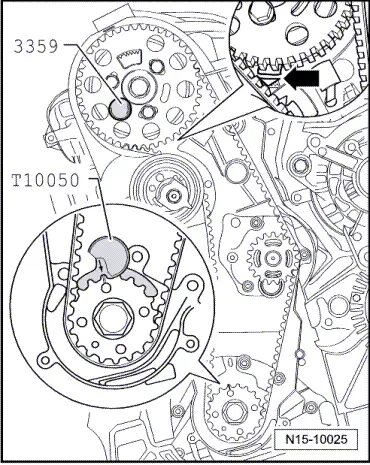

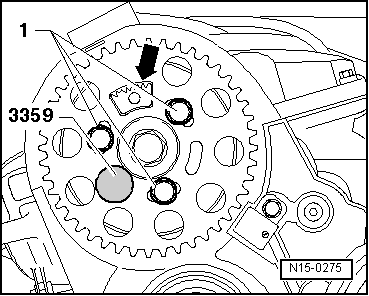

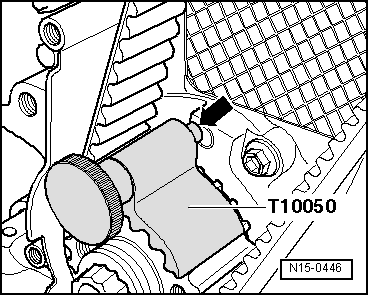

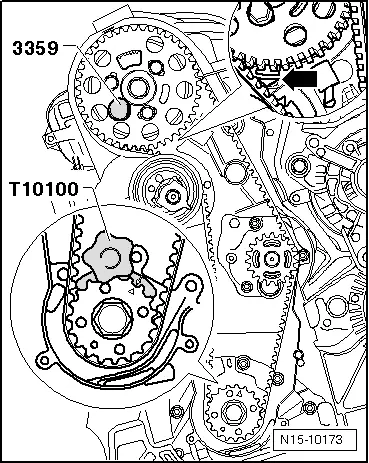

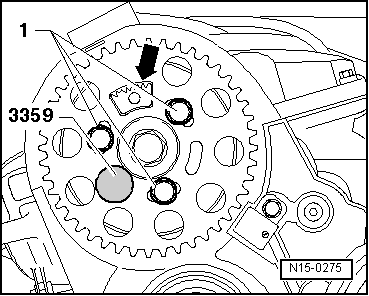

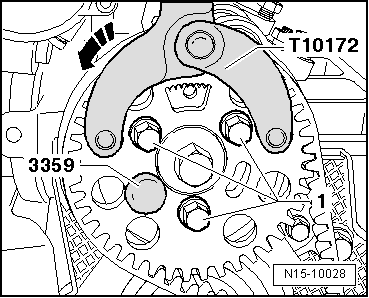

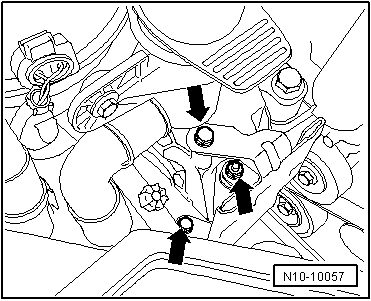

| From model year 2004, a new toothed belt tensioner is installed. The tensioner has an additional hexagon hole -arrow-. To tension and release toothed belt, use Allen key instead of pin wrench -T10020-. This does not alter the procedure. |

Note | Adjustment work on toothed belts must be performed only on cold engines, as the indicator position on the tensioning element varies depending on the engine temperature. |

| –

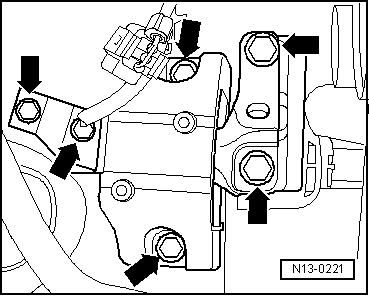

| Remove coolant expansion tank, coolant hoses remain connected. |

| –

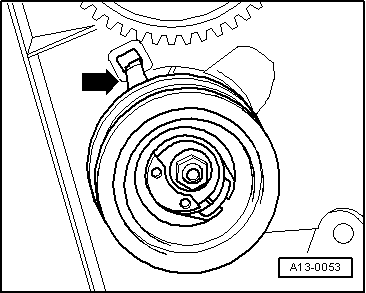

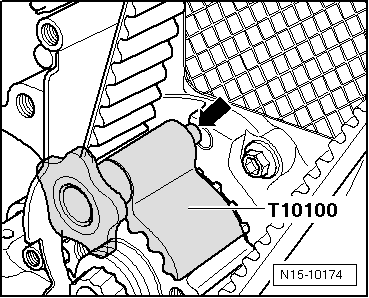

| Remove tensioning element for poly V-belt. |

| –

| Remove front right wheel housing liner. |

| –

| Remove charge air pipe between charge air cooler and turbocharger. → Chapter |

| –

| Carefully cover or seal open ends. |

| –

| Remove belt pulley with vibration damper. |

| –

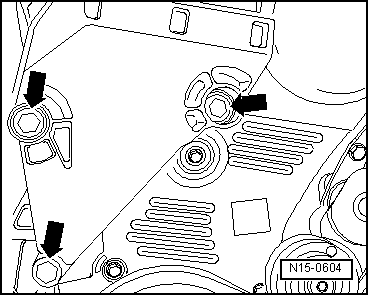

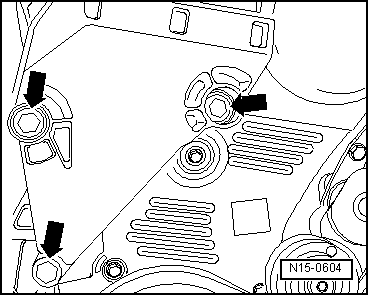

| Remove lower and centre parts of toothed belt guard. |

|

|

|

Note

Note Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

WARNING

WARNING