| –

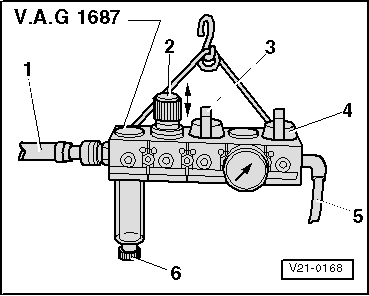

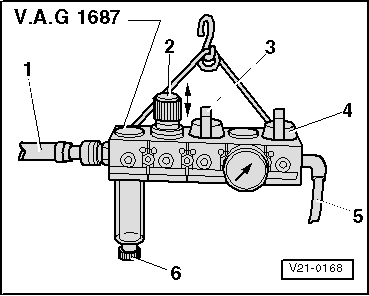

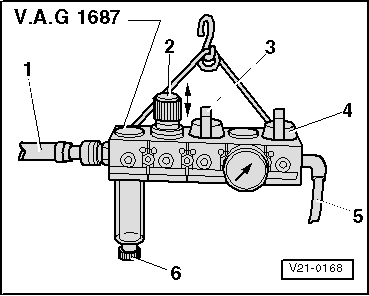

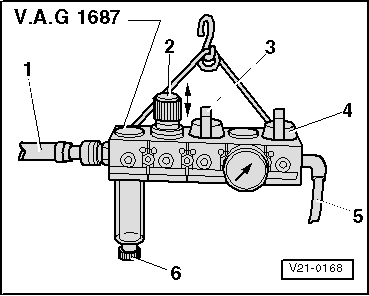

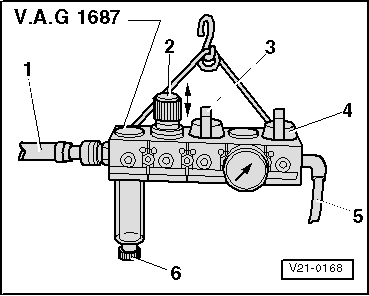

| Connect compressed air hose -1- (compressed air source) to charge air system tester -V.A.G 1687-. |

Note | If there is water in the sight glass, drain at water drain screw -6-. |

| –

| Adjust pressure to 1.0 bar with pressure regulating valve -2-. |

Caution | The maximum test pressure is 1.3 bar and this must not be exceeded. |

|

| –

| Open valve -4- and wait until the test circuit is filled. If necessary readjust pressure to 1.0 bar. |

| –

| Close valve -3- to retain pressure and observe the pressure drop over a period of 1 minute. |

| If the pressure does not drop the tandem pump can be reused, if the pressure drops the tandem pump must be renewed. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note